Coating waste solvent recovery technology

A waste solvent and process technology, which is applied in the field of painting waste solvent recovery process, can solve the problems of difficult recovery, waste of valuable solvent resources, increased difficulty of hazardous waste incineration and difficulty of incineration tail gas treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

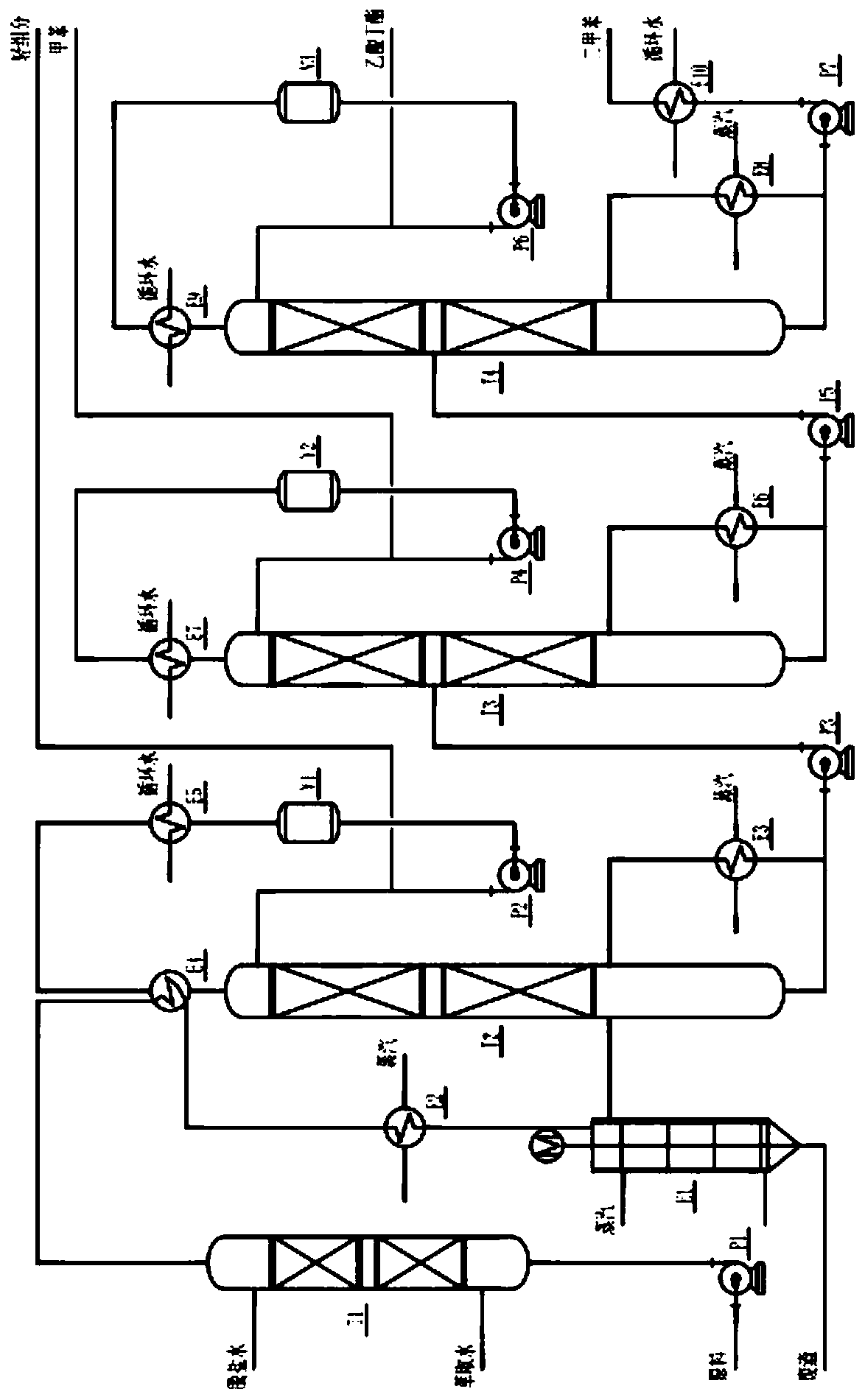

[0039] Recycling process see figure 1 ,in

[0040] P1-feed pump; P2-dehydrogenation reflux pump; P3-dehydrogenation discharge pump; P4-toluene reflux pump; P5-discharge pump; P6-butyl ester reflux pump; P7-xylene discharge pump; T1- Extraction tower; T2-light removal tower; T3-toluene tower; T4-xylene tower; E1-evaporator; E2-preheater; E3-dehydrogenation reboiler; E4-dehydrogenation condenser; E5-dehydrogenation Cooler; E6-Toluene Reboiler; E7-Toluene Condenser; E8-Xylene Reboiler; E9-Xylene Condenser; E10-Xylene Cooler; V1-Light Component Reflux Tank; V2-Toluene Reflux Tank; V3-Butyl Reflux Tank.

[0041] The specific operation steps are as follows:

[0042] (1) Extraction

[0043] Use desalted water as the extractant to extract ethanol, isopropanol, water and water-soluble resin from the waste coating solvent. Through actual operation, the volume flow ratio of desalted water to the waste coating solvent is controlled at 1:4 .

[0044] (2) Removal of impurities

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com