Modified silica gel material, and preparation method and application thereof

A silica gel and modified technology, applied in the field of materials, can solve the problem that it is difficult to adjust the ratio of polar groups and non-polar groups, the position and number of polar groups are not fixed, and the reproducibility of fillers is difficult to ensure. problems, to achieve the effect of superior water resistance, increased hydrophilicity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

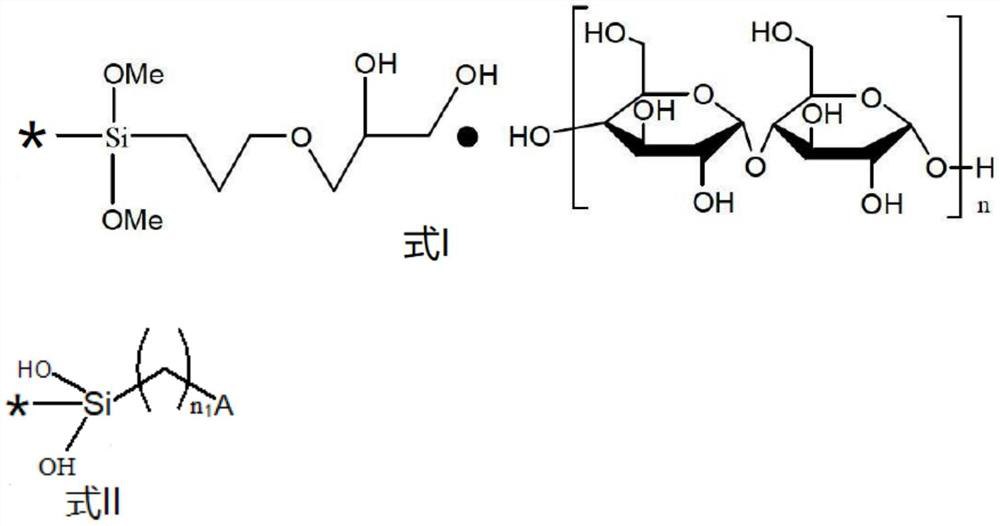

[0098] The present application provides a preparation method of a modified silica gel material to solve the problems of poor water resistance, poor selectivity and short life when the silica gel material in the prior art is used as a chromatographic column. The preparation method of modified silica gel material comprises the steps:

[0099] 1) Silane coupling agent modified silica gel and hydrophilic polymer carry out cross-linking reaction to obtain hydrophilic modified silica gel;

[0100] 2) Substituting the hydrophilic modified silica gel with a non-polar silane reagent to obtain hydrophobic modified silica gel;

[0101] 3) Substituting the hydrophobically modified silica gel with a polar silane reagent to obtain the modified silica gel material.

[0102] The concrete route of the preparation method of modified silicon material in the present application is as follows:

[0103]

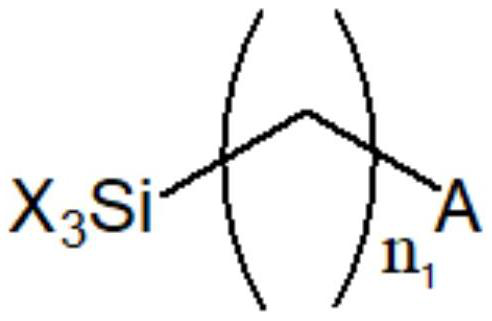

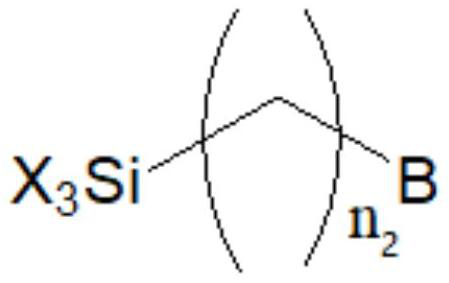

[0104] In this application, the active silanol on the surface of the silica gel reacts wi...

Embodiment 1

[0107] In this embodiment, the modified silica gel material and its preparation method include the following:

[0108] 1) 50g of spherical silica gel and 100g of γ-(2,3-glycidoxy)propyltrimethoxysilane were dispersed in 250mL of toluene solution, and reacted at 80°C for 2h to obtain 53g of silane coupling agent modified silica gel.

[0109] 2) Add 100g of soluble starch to the above 53g of silane coupling agent-modified silica gel, and reflux at 97°C for cross-linking reaction for 20h; after the reaction, cool and reflux for 12h; wash with 200mL distilled water, 200mL tetrahydrofuran and 200mL acetonitrile, and filter , to obtain hydrophilic modified silica gel.

[0110] 3) Add 250mL of toluene, 50g of octadecyltrichlorosilane, and 2g of triethylamine in sequence to the above-mentioned hydrophilic modified silica gel, and reflux and stir at 105°C for 1 hour; Wash with methanol, filter, and repeat this step once; dry in the air, and vacuum dry at 105° C. for 2 hours to obtain ...

Embodiment 2

[0113] In this embodiment, the modified silica gel material and its preparation method include the following:

[0114] 1) 50g of spherical silica gel and 100g of γ-(2,3-glycidoxy)propyltrimethoxysilane were dispersed in 250mL of toluene solution, and reacted at 80°C for 2h to obtain 53g of silane coupling agent modified silica gel.

[0115] 2) Add 100g of soluble starch to the above 53g of silane coupling agent-modified silica gel, and reflux at 97°C for cross-linking reaction for 20h; after the reaction, cool and reflux for 12h; wash with 200mL distilled water, 200mL tetrahydrofuran and 200mL acetonitrile, and filter , to obtain hydrophilic modified silica gel.

[0116] 3) Add 250mL of toluene, 50g of octyltrichlorosilane, and 2g of triethylamine in sequence to the above-mentioned hydrophilic modified silica gel, and reflux and stir at 105°C for 1 hour; after the reaction, add 400mL of distilled water and 400mL of methanol Wash, filter, and repeat this step once; dry in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com