Dual-curable polyurethane toughened resin and preparation method and application thereof

A toughened resin and dual curing technology, which is applied in the field of dual curable polyurethane toughened resin and its preparation, can solve the problems of reduced curing speed, reduced adhesion, and reduced Tg, to achieve increased curing speed, improved adhesion, and volume small shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of PPG1000-PU

[0030] S1. First mix 26.78g of 3-oxetanemethanol with 34.09g of hydroxyethyl acrylate (molar ratio 1:1) to obtain substance A;

[0031] Another 135.12 g of isophorone diisocyanate (IPDI) were added to obtain substance B;

[0032] Add 0.5 g of the polymerization inhibitor p-hydroxyanisole and 0.5 g of the catalyst dibutyltin dilaurate to the substance B, mix them uniformly, and maintain the reaction at 60 ° C for 2 hours to obtain the isocyanate semi-blocked composition C;

[0033] S2. Add 304.01 g of macromolecular polyol polypropylene glycol 2000 (PPG2000, 2-functional) according to the molar ratio of the composition to the reactive group in the macromolecular polyol -NCO:-OH=1:1 and keep it at 70°C for 6 hours to react. The finished product PPG1000-PU can be obtained.

Embodiment 2

[0035] Preparation of PPG600-PU

[0036] S1. First mix 58.75g of 3-methyl-3-hydroxymethyloxetane and 37.43g of hydroxypropyl acrylate (molar ratio 1:0.5) evenly to obtain substance A;

[0037] 144.96 g of hexamethylene diisocyanate (IPDI) were added to obtain substance B;

[0038] Add 0.4g of the polymerization inhibitor p-hydroxyanisole and 0.4g of the catalyst dibutyltin dilaurate to the substance B, mix them uniformly, and then maintain the reaction at 50°C for 3 hours to obtain the isocyanate semi-blocked composition C;

[0039] S2. According to the molar ratio of the composition to the reactive group in the macromolecular polyol -NCO:-OH=1:1, add 258.86g macromolecular polyol polyethylene glycol 600 (PEG600, 2 functional) and keep it at 80°C for reaction 4 The finished product PPG600-PU can be obtained within hours.

Embodiment 3

[0041] Preparation of PTMG1400-PU

[0042] S1. First mix 21.21g of 3-oxetanepropanol and 39.49g of hydroxybutyl acrylate (molar ratio 1:1.5) evenly to obtain substance A;

[0043] An additional 119.76 g of dicyclohexylmethane diisocyanate (HMDI) was added to obtain substance B;

[0044] Add 0.45g of polymerization inhibitor p-hydroxyanisole and 0.45g of catalyst organic bismuth catalyst bismuth neodecanoate to substance B, mix uniformly and maintain 40°C for 4 hours to obtain isocyanate semi-blocked composition C;

[0045] S2. According to the molar ratio of the composition to the reactive group in the macromolecular polyol -NCO:-OH=1:1, add 319.54g macromolecular polyol polytetrahydrofuran ether 1400 (PTMG1400, 2 functional) and keep it at 88°C for 3 hours. The finished product PTMG1400-PU can be obtained.

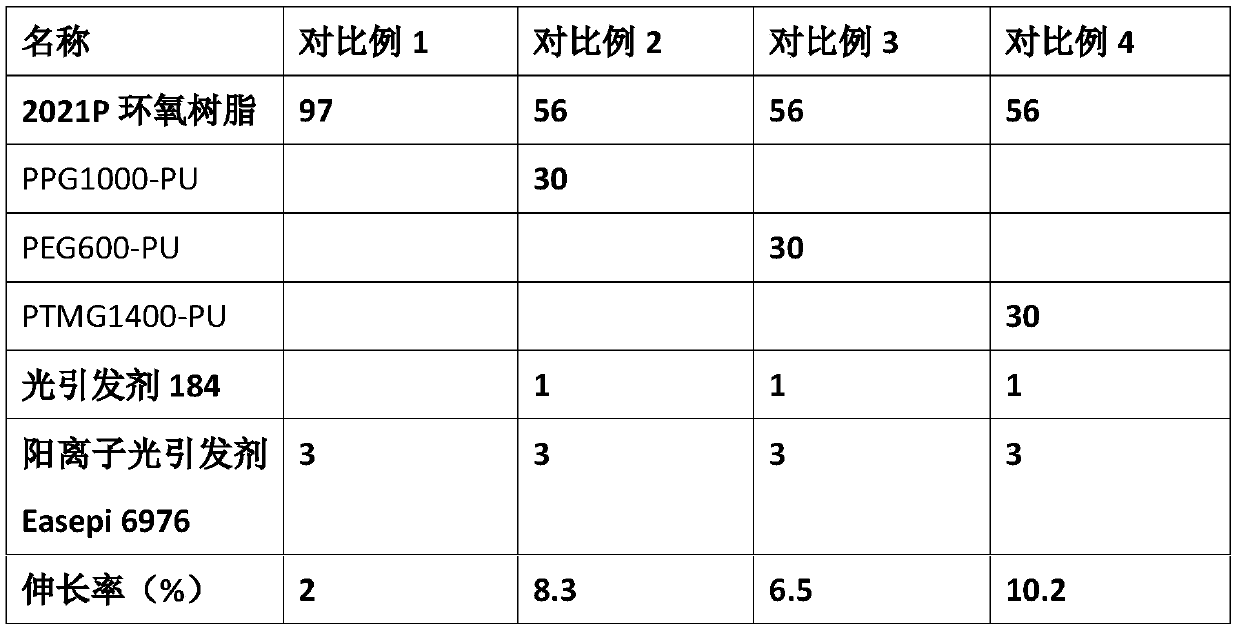

[0046] The application effects of the foregoing embodiments of the present invention are as follows:

[0047] Four sets of comparative examples were designed as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com