Method for preparing thin films in different components and doping ratios through multi-target co-sputtering

A co-sputtering and thin-film technology, which is applied in the field of thin-film preparation that can flexibly adjust the composition and doping ratio, can solve the problems of not being prepared, not being able to obtain a thin film, and being unable to flexibly adjust the VO phase transition temperature, etc., to achieve repeatability Strong, low production cost, good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

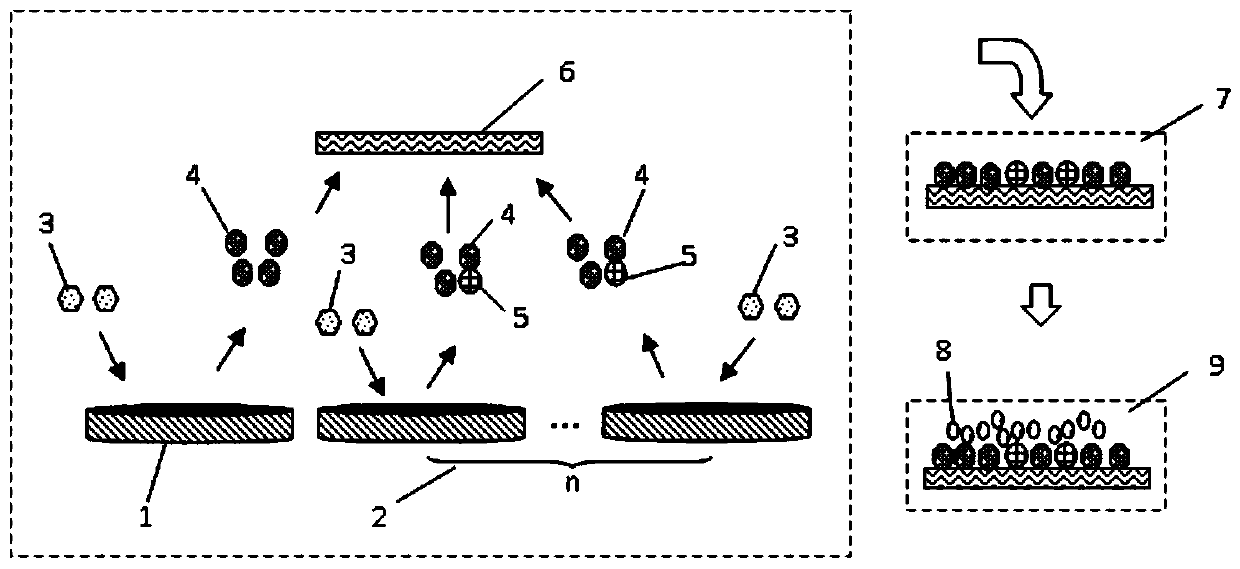

Method used

Image

Examples

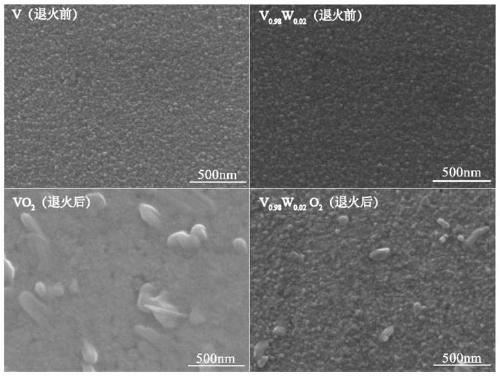

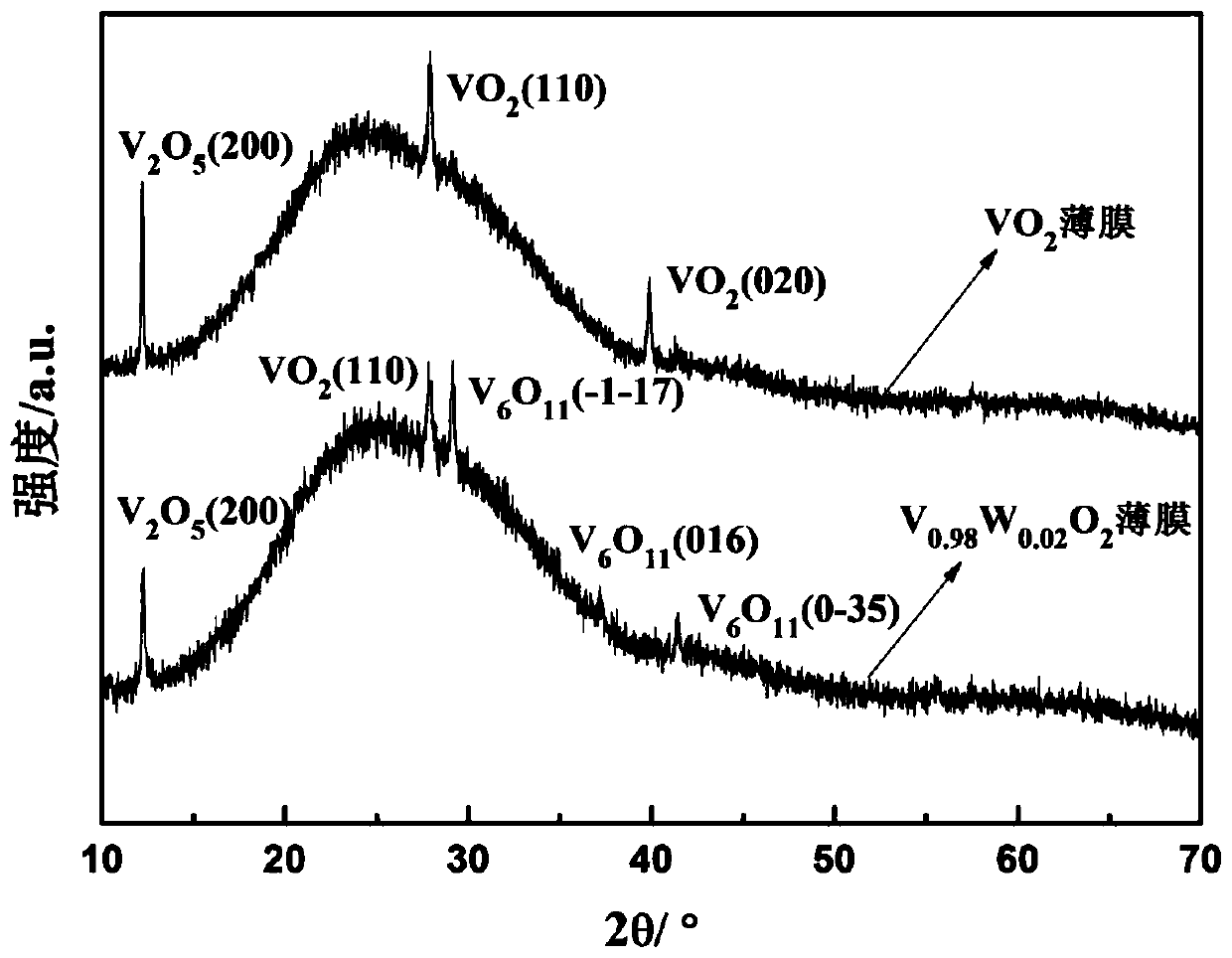

Embodiment 1

[0031] In this example, a VW film with a specific W doping ratio is deposited on an amorphous K9 glass substrate by double-target co-sputtering with a fixed power ratio of 500W:0W. The VW atomic ratio in the vanadium-tungsten target is 98:2. Then, VO with specific W doping ratio was prepared by vacuum pre-annealing and oxidation annealing process. 2 thin films, and finally tested the prepared doped VO 2 Film transmission properties. The specific implementation steps are as follows:

[0032] 1. Substrate cleaning. Put the amorphous K9 glass substrate into an acetone solution (MOS grade, purity greater than 99.8%) for 5 minutes, and then put it into an anhydrous ethanol solution (MOS grade, purity greater than 99.7%) for 5 minutes to remove oil on the surface of the substrate , after ultrasonic cleaning, take it out vertically and dry it with nitrogen.

[0033] 2. Place the cleaned substrate in the input cavity of the magnetron sputtering coating line, and evacuate to 9.9×10...

Embodiment 2

[0039] In this example, a VW thin film with a specific W doping ratio is deposited on an amorphous K9 glass substrate by double-target co-sputtering with a fixed power ratio of 500W:250W. The VW atomic ratio in the vanadium-tungsten target is 98:2. Then prepare VO with a certain W doping ratio by vacuum pre-annealing and oxidation annealing process 2 thin films, and finally tested the prepared doped VO 2 Film transmission properties. The specific implementation steps are as follows:

[0040] 1. Substrate cleaning. Put the amorphous K9 glass substrate into an acetone solution (MOS grade, purity greater than 99.8%) for 5 minutes, and then put it into an anhydrous ethanol solution (MOS grade, purity greater than 99.7%) for 5 minutes to remove oil on the surface of the substrate , after ultrasonic cleaning, take it out vertically and dry it with nitrogen.

[0041] 2. Place the cleaned substrate in the input cavity of the magnetron sputtering coating line, and evacuate to 9.9×1...

Embodiment 3

[0047] In this example, a VW thin film with a specific W doping ratio is plated on an amorphous K9 glass substrate by double-target co-sputtering with a fixed power ratio of 500W:500W. The VW atomic ratio in the vanadium-tungsten target is 98:2. Then prepare VO with a certain W doping ratio by vacuum pre-annealing and oxidation annealing process 2 thin films, and finally tested the prepared doped VO 2 Film transmission properties. The specific implementation steps are as follows:

[0048] 1. Substrate cleaning. Put the amorphous K9 glass substrate into an acetone solution (MOS grade, purity greater than 99.8%) for 5 minutes, and then put it into an anhydrous ethanol solution (MOS grade, purity greater than 99.7%) for 5 minutes to remove oil on the surface of the substrate , after ultrasonic cleaning, take it out vertically and dry it with nitrogen.

[0049] 2. Place the cleaned substrate in the input cavity of the magnetron sputtering coating line, and evacuate to 9.9×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com