Preparation method of silicon-copper composite nanowire

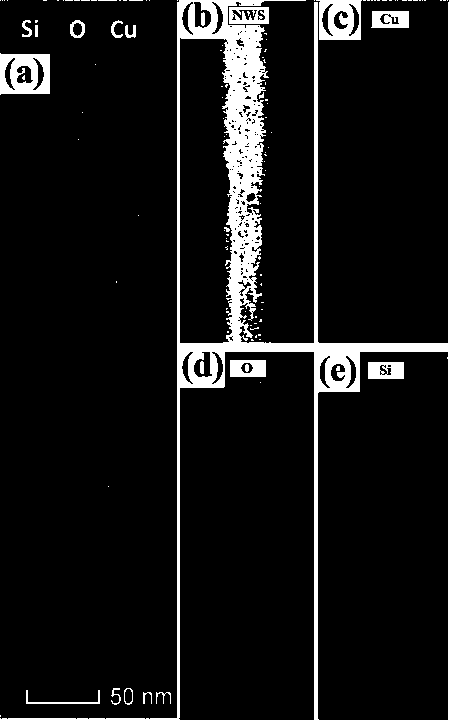

A nanowire and silicon-copper technology, which is applied in the field of preparation of silicon-copper composite nanowires, can solve the problems of high cost and poor uniformity, and achieve the effect of overcoming the difficulty of in-situ compounding, high conductivity, and uniform distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

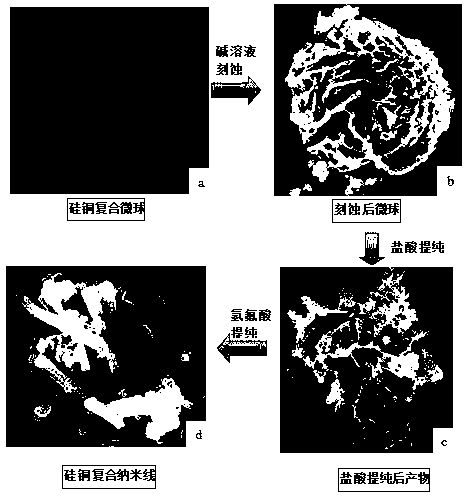

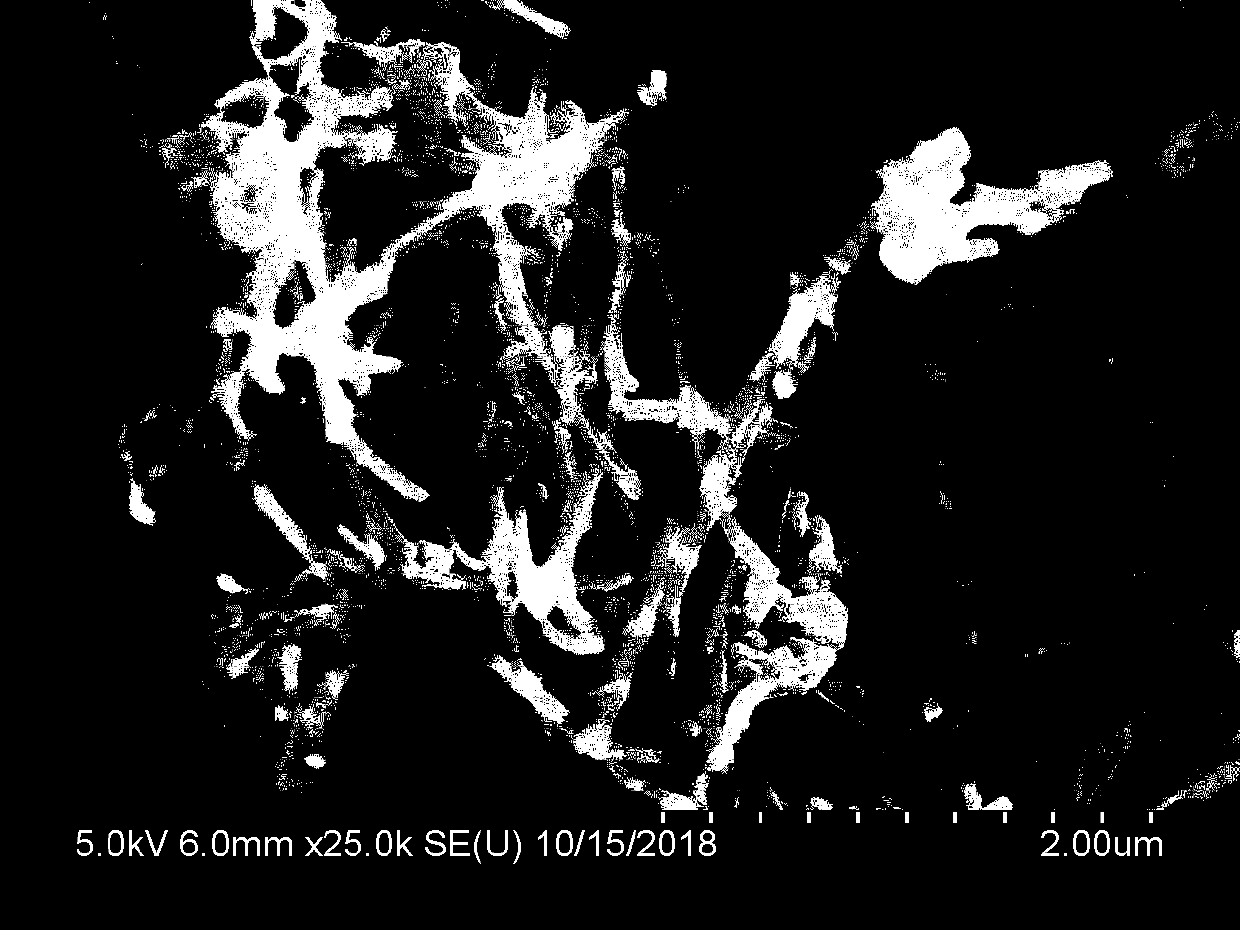

[0037] This embodiment provides a method for preparing silicon-copper composite nanowires using silicon-copper composite microspheres. When silicon-copper composite microspheres are used as raw materials, chemical etching and purification are used to prepare silicon-copper composite nanowires. The specific steps are as follows:

[0038] 1) Select P-type single crystal silicon master alloy with electrical conductivity of 0.01~0.015Ω·cm as the raw material, and process it by pulse discharge method. The processing parameters are: open circuit voltage 120V; peak current 5A; pulse width 50µs; duty ratio 1:2 , the working fluid is deionized water, and the electrode is copper electrode. Process and collect doped silicon-copper composite microspheres. The particle size range of silicon-copper composite microspheres is 1-5µm, the size is concentrated at 3µm, and the concentration is greater than 90%.

[0039] 2) Measure 10g of silicon-copper composite microspheres as the matrix materia...

Embodiment 2

[0050] This embodiment provides a method for preparing silicon-copper composite nanowires using silicon-copper composite microspheres. When silicon-copper composite microspheres are used as raw materials, chemical etching and purification are used to prepare silicon-copper composite nanowires. The specific steps are as follows:

[0051] 1) Select P-type single crystal silicon master alloy with electrical conductivity of 0.01~0.015Ω·cm as the raw material, and process it by pulse discharge method. The processing parameters are: open circuit voltage 120V; peak current 5A; pulse width 50µs; duty ratio 1:2 , the working fluid is deionized water, and the electrode is copper electrode. Process and collect doped silicon-copper composite microspheres. The particle size range of silicon-copper composite microspheres is 1-5µm, the size is concentrated at 3µm, and the concentration is greater than 90%.

[0052] 2) Measure 10g of silicon-copper composite microspheres as the matrix materia...

Embodiment 3

[0063] This embodiment provides a method for preparing silicon-copper composite nanowires using silicon-copper composite microspheres. When silicon-copper composite microspheres are used as raw materials, chemical etching and purification are used to prepare silicon-copper composite nanowires. The specific steps are as follows:

[0064] 1) Select P-type single crystal silicon master alloy with electrical conductivity of 0.01~0.015Ω·cm as the raw material, and process it by pulse discharge method. The processing parameters are: open circuit voltage 120V; peak current 5A; pulse width 50µs; duty ratio 1:2 , the working fluid is deionized water, and the electrode is copper electrode. Process and collect doped silicon-copper composite microspheres. The particle size range of silicon-copper composite microspheres is 1-5µm, the size is concentrated at 3µm, and the concentration is greater than 90%.

[0065] 2) Measure 10g of silicon-copper composite microspheres as the matrix materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com