Novel fermentation systems and methods

A yeast and composition technology, applied in the field of production of microorganism-based compositions, can solve problems such as loss of viability and/or activity, inability of microorganisms to reproduce or even survive, and inability to effectively compete with microorganism groups, so as to promote portability and improve microbial The effect of product yield and transportation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0109] Preparation of Microbial-Based Products

[0110] Microbial-based products of the present invention include microbes and / or microbial growth by-products and optionally, growth media and / or additional ingredients such as, for example, water, carriers, adjuvants, nutrients, viscosity modifiers, and other active agents. product.

[0111] A microorganism-based product of the present invention is simply the fermentation medium comprising the microorganism and / or the by-products of microbial growth and / or any residual nutrients produced by the microorganism. The fermented product can be used directly without extraction or purification. Extraction or purification can be performed, if desired, using standard extraction methods or techniques known to those skilled in the art.

[0112] The microorganisms in the microorganism-based product may be in active or inactive form and / or exist as vegetative cells, spores, mycelia, conidia and / or any other form of microbial propagules. M...

Embodiment 1-

[0155] Embodiment 1-multi-tank fermentation system

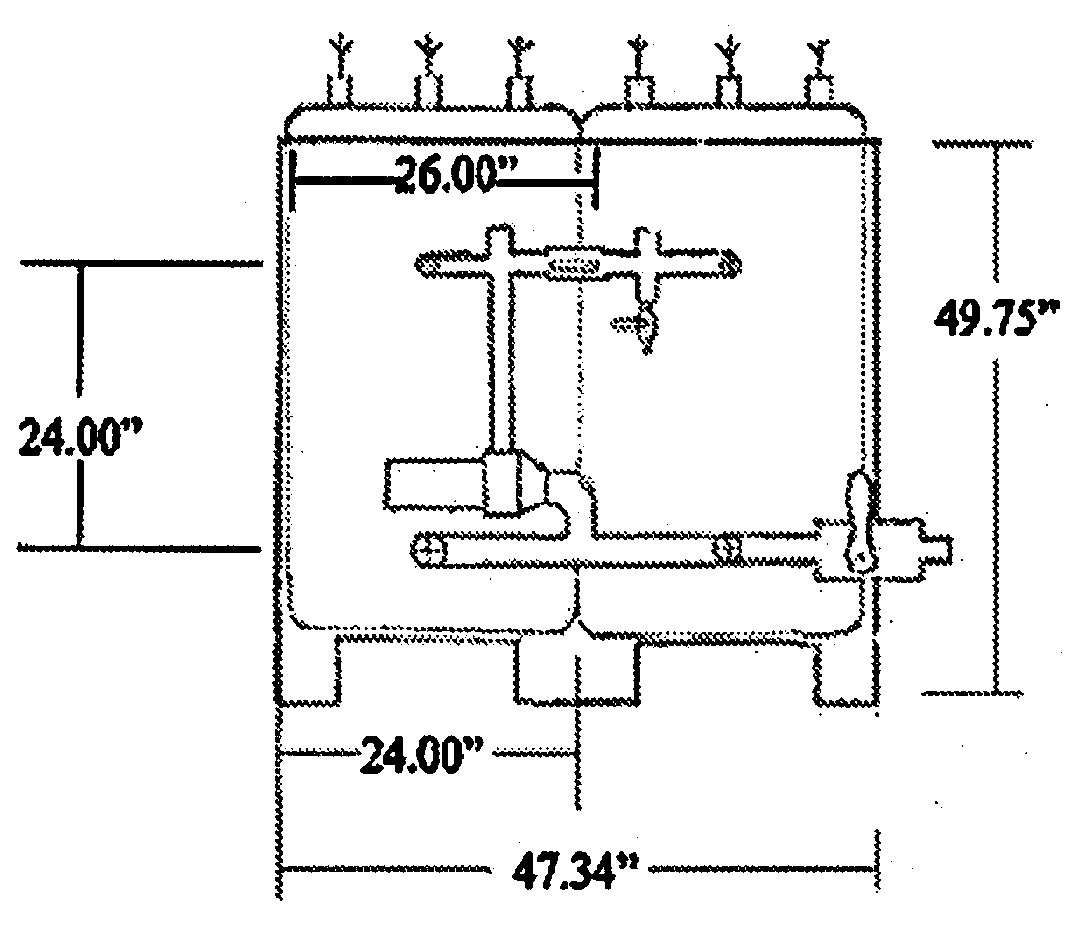

[0156] figure 1 and figure 2 A portable and dispensable plastic reactor is shown. The reactor has two plastic square tanks with two loops for mass exchange between the two tanks.

[0157] The top of the system is equipped with a pumping mechanism that pulls from the first tank and stores to the second tank, which is one in the loop. Another loop is at the bottom of the tank and relies on hydrostatic pressure to equalize the volume within the tank.

[0158] The addition of filtered air to the tank is controlled by a spray mechanism run through a bubbler. Filtered air for spraying is generated via a high volume aquatic pumping system. There are two 72-inch bubblers per tank, so there are a total of four of these bubblers in each system. An air compressor is also used to add filtered air to the top and bottom loops for additional ventilation.

[0159] The top loop is equipped with viewing glasses to observe the turbidit...

Embodiment 2

[0165] Embodiment 2-culture medium and its use in multi-tank reactors for the cultivation of Torulopsis sphaeroides

[0166] Prepare medium in filtered water consisting of: 20-100gL -1 Glucose, 0-50gL -1 (It can vary eg depending on the desired amount of biosurfactant to be produced) Rapeseed oil, 5gL -1 Yeast extract, 4gL - 1 NH 4 Cl, 1gL -1 K H 2 PO 4 .H 2 O, 0.1gL -1 NaCl and 0.5gL -1 MgSO 4 .7H 2 O.

[0167] The initial pH was adjusted to about 4.5 with 6N KOH. Cultures were grown at about 25°C. The incubation time was up to 120 hours, and the pH of the reactor culture was adjusted to about 3.5 twice a day by adding 1.0 M NaOH.

[0168] Under these culture conditions, Torulopsis globosa wet biomass reached 100 grams per liter of culture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com