Plated steel sheet having multilayer structure and manufacturing method therefor

A technology of multi-layer structure and manufacturing method, which is applied in the field of plated steel plate, and can solve problems such as easy peeling off of the plating layer, failure to apply, and brittle cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

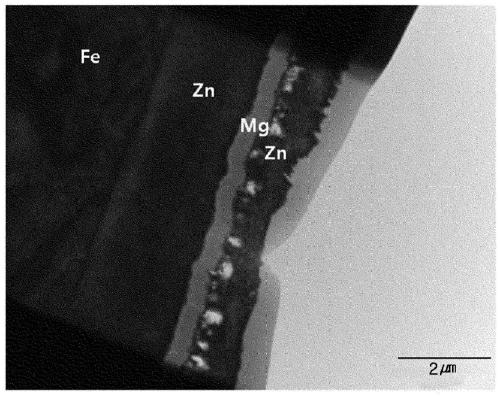

[0046] A general cold-rolled steel sheet is prepared as a base steel sheet, and then a first Zn layer is formed by an ordinary electrogalvanizing method.

[0047] Then, the steel plate is put into a vacuum chamber, and the foreign matter and natural oxide film on the surface are removed by plasma pretreatment, and then the second Mg layer and the third Zn layer are formed by electromagnetic levitation induction heating deposition method. Table 1 shows the thickness of each layer and the temperature at the time of deposition. When vacuum depositing the second Mg layer and the third Zn layer, the vacuum degree inside the chamber was kept at about 2×10 -2 ~9×10 -4 between mbars.

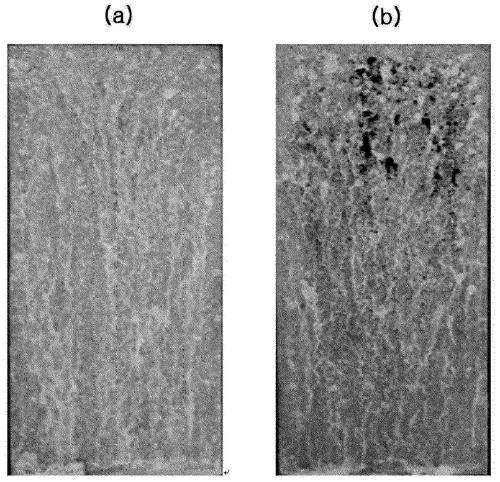

[0048] For the multilayer plated steel sheets manufactured as described above, blackening resistance, plating adhesion, corrosion resistance, etc. were evaluated and shown in Table 1 together.

[0049] At this time, for the evaluation of blackening resistance, the color difference before and after ho...

Embodiment 2

[0063] Next, under the same conditions as in Example 1, the first Zn layer, the second Mg layer, and the third Zn layer were produced to have thicknesses of 1 μm, 1 μm, and 3 μm, respectively. However, when vacuum-depositing the second Mg layer and the third Zn layer, the temperature of the substrate is varied from normal temperature to 160° C., and the degree of Zn diffusion of the third Zn layer is adjusted to produce a plated steel sheet.

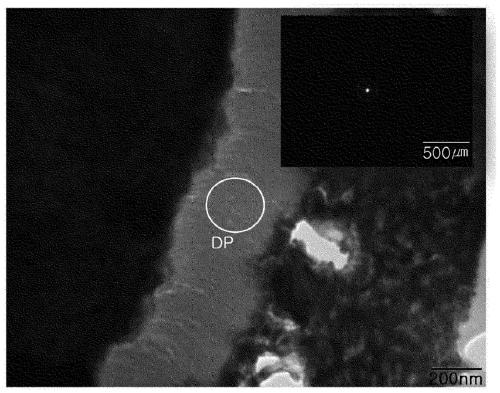

[0064] For the plated steel sheets manufactured as described above, blackening resistance, plating adhesion, corrosion resistance and phase analysis were evaluated in the same manner as in Example 1, and the results are shown in Table 2 below. Table 2 also shows the results of analyzing the cross-section of the second Mg layer by transmission electron microscope-energy dispersive spectroscopy (TEM-EDS) point analysis with respect to the weight ratio of Zn diffused into the second Mg layer.

[0065] [Table 2]

[0066]

[0067] It was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com