Calcium citrate/polylactic acid bone repair material prepared by melt blending method and application thereof

A calcium citrate, melt blending technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of acidity of degradation products, inflammation, etc., achieve good biocompatibility, promote growth, and have obvious composite effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The calcium citrate / polylactic acid bone repair material prepared by the melt blending method provided in this example is composed of polylactic acid and calcium citrate, in terms of mass percentage, the content of calcium citrate is 20%, and the rest is polylactic acid; citric acid The calcium is calcium citrate tetrahydrate, and the molecular weight of polylactic acid is 200,000. The specific implementation steps are as follows:

[0027] (1) Weigh 8 grams of polylactic acid and 2 grams of calcium citrate with an electronic balance;

[0028] (2) Melt and blend the weighed polylactic acid and calcium citrate at 180°C, and stir to obtain a uniformly dispersed mixture; the stirring speed is 200r / min;

[0029] (3) The mixture was injected into the template, and after 3 minutes of natural cooling to room temperature, the calcium citrate / polylactic acid bone repair material prepared by melt blending was prepared.

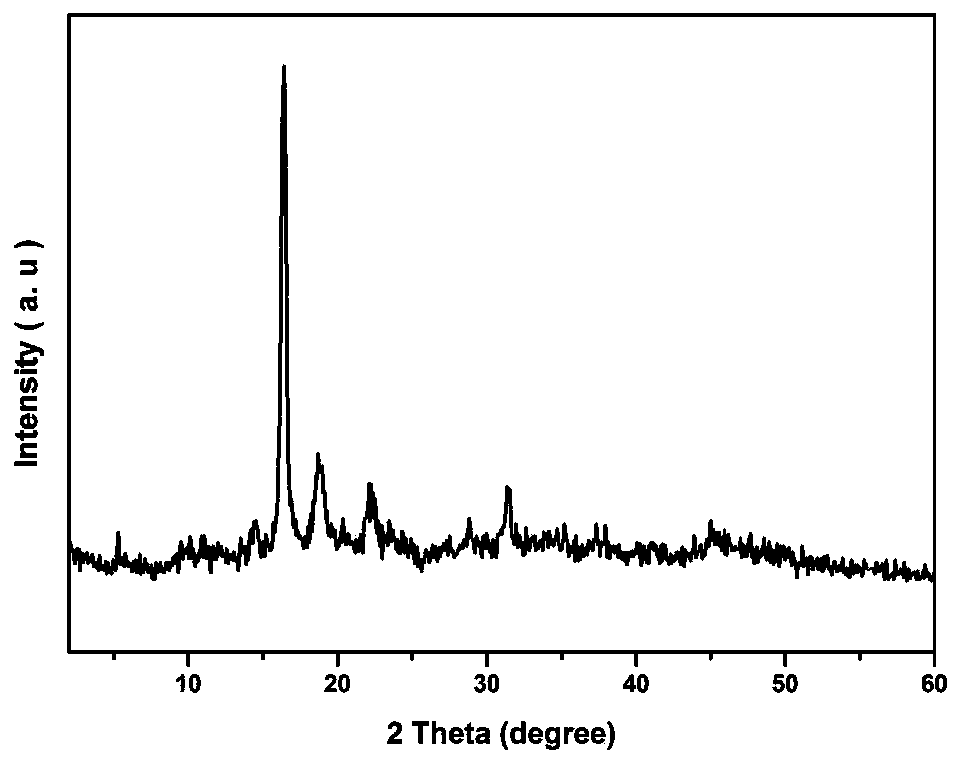

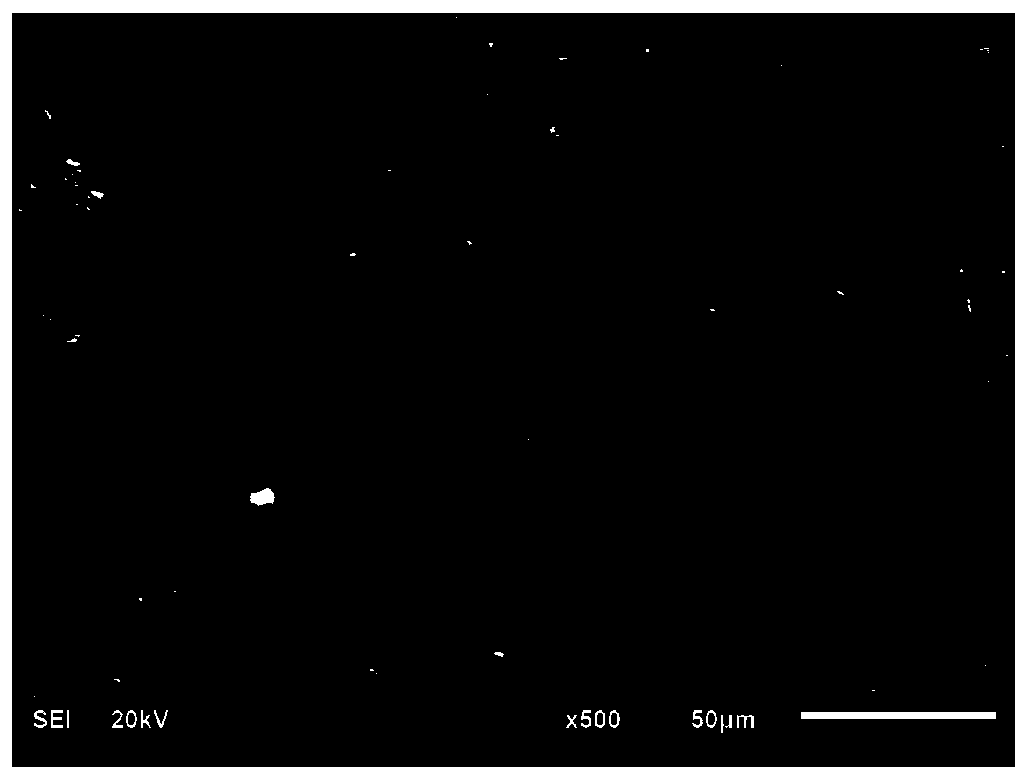

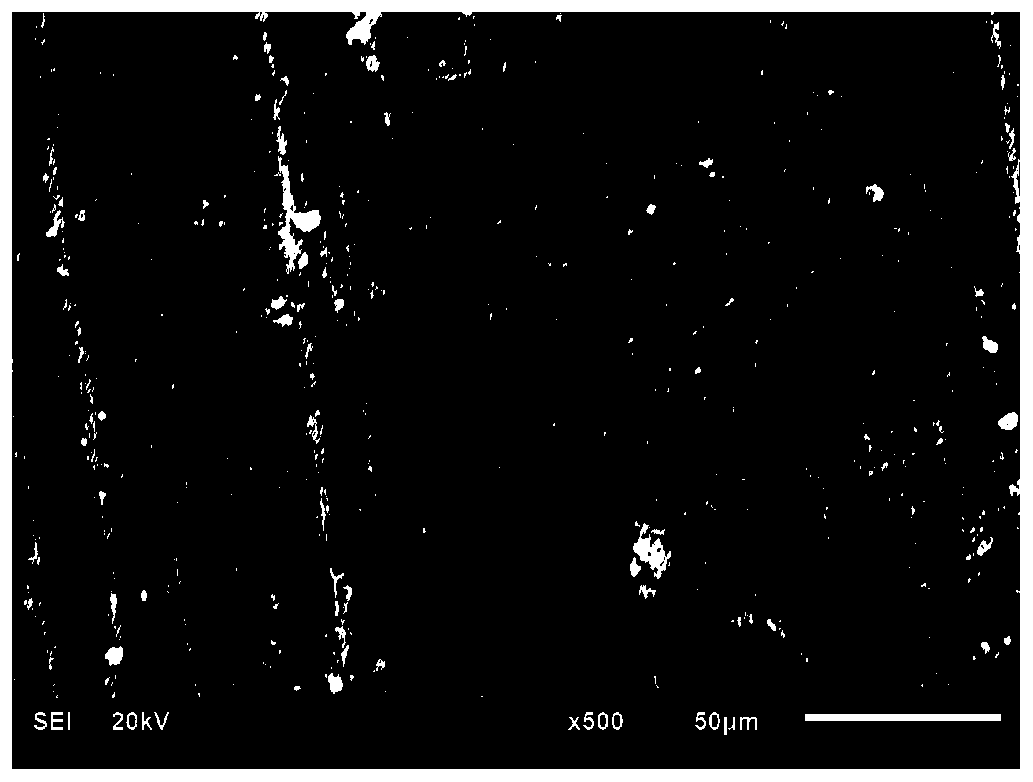

[0030] figure 1 It is the XRD pattern of the calcium citr...

Embodiment 2

[0037] The calcium citrate / polylactic acid bone repair material prepared by the melt blending method in this embodiment is composed of polylactic acid and calcium citrate. In terms of mass percentage, the content of calcium citrate is 1%, and the rest is polylactic acid; calcium citrate is Calcium citrate tetrahydrate, the molecular weight of polylactic acid is 200,000.

[0038] (1) Take by weighing 9.9 grams of polylactic acid and 0.1 grams of calcium citrate with an electronic balance;

[0039] (2) Melt-blending the weighed polylactic acid and calcium citrate together at 180° C., and obtaining a uniformly dispersed mixture by stirring; the stirring speed is 100 r / min;

[0040] (3) The mixture was poured into the template, and allowed to cool naturally to room temperature for 5 minutes to prepare a calcium citrate / polylactic acid bone repair material prepared by the melt blending method.

[0041] The tensile strength and elastic modulus of the calcium citrate / polylactic acid...

Embodiment 3

[0044] The calcium citrate / polylactic acid bone repair material prepared by the melt blending method in this embodiment is composed of polylactic acid and calcium citrate. In terms of mass percentage, the content of calcium citrate is 10%, and the rest is polylactic acid; calcium citrate is Calcium citrate tetrahydrate, polylactic acid molecular weight 200,000

[0045] (1) Take 9 grams of polylactic acid and 1 gram of calcium citrate with an electronic balance;

[0046] (2) Melt blend the weighed polylactic acid and calcium citrate at 180°C, and disperse evenly under stirring to obtain a mixture; the stirring speed is 200r / min;

[0047] (3) The mixture was injected into the template, and after being cooled to room temperature, the calcium citrate / polylactic acid bone repair material prepared by the melt blending method was obtained.

[0048] The tensile strength and elastic modulus of the calcium citrate / polylactic acid bone repair material prepared by the melt blending metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com