Treatment process of low-carbon steel-zinc aluminum stainless steel composite material

A composite material and processing technology, which is applied in the processing technology field of low carbon steel-zinc-aluminum stainless steel composite materials, can solve the problems of environmental pollution and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

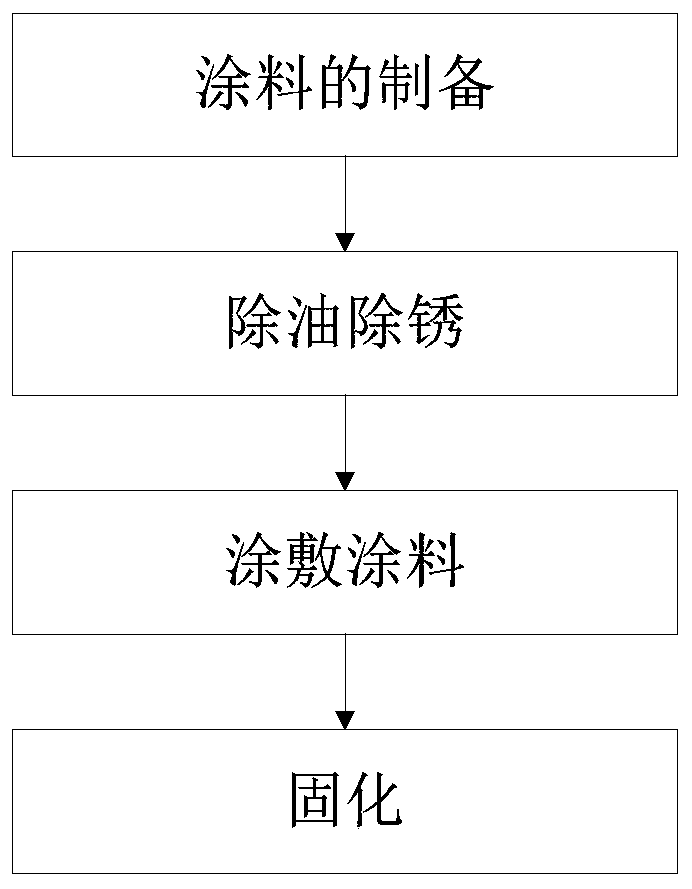

[0018] (1) Preparation of coating: First, weigh a certain amount of high molecular polymer 8586, and then add a certain amount of water to dilute to obtain high molecular polymer 8586 aqueous solution, the concentration of high molecular polymer 8586 aqueous solution is 75%-80%, The mass ratio of high molecular polymer 8586 to water is (2-6): 1, finally add titanium powder and zinc powder, the mass percentage of zinc powder and titanium powder is 10%-100%, the mixture of titanium powder and zinc powder and The mass ratio of the high molecular polymer 8586 aqueous solution is 2.0: (1.6-2.4), and the coating is obtained by stirring evenly;

[0019] (2) degreasing and derusting: degreasing and derusting the prepared steel sheet;

[0020] (3) Coating: the above-mentioned steel sheet after degreasing and derusting is wiped with filter paper to obtain a pretreated steel sheet, and the coating is applied on the pretreated steel sheet;

[0021] (4) Curing: heat and cure the coated st...

Embodiment 1

[0023] A treatment process for low-carbon steel-zinc-aluminum stainless steel composite material, comprising the following steps:

[0024] (1) Preparation of coating: first weigh a certain amount of high molecular polymer 8586, then add a certain amount of water to dilute to obtain high molecular polymer 8586 aqueous solution, the concentration of high molecular polymer 8586 aqueous solution is 75%, finally add titanium Powder and zinc powder, the mass percentage of zinc powder and titanium powder is 30%, the mass ratio of the mixture of titanium powder and zinc powder and high molecular polymer 8586 aqueous solution is 2.0: 2.0, stir to obtain coating;

[0025] (2) degreasing and derusting: degreasing and derusting the prepared steel sheet;

[0026] (3) Coating: the above-mentioned steel sheet after degreasing and derusting is wiped with filter paper to obtain a pretreated steel sheet, and the coating is applied on the pretreated steel sheet;

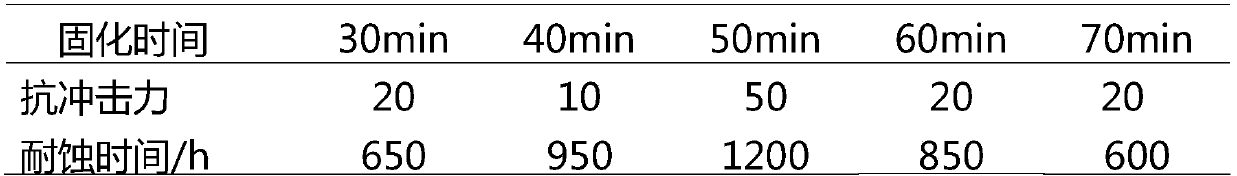

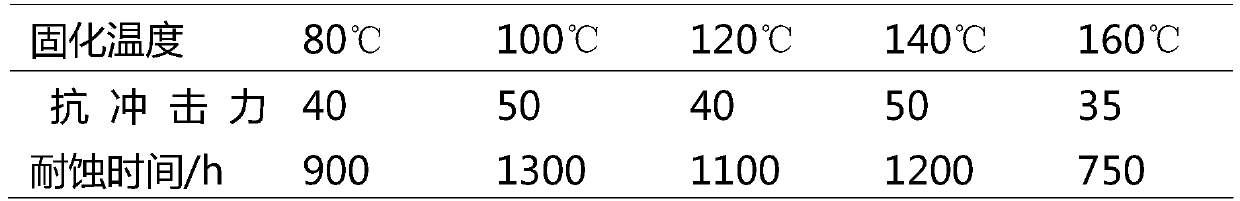

[0027] (4) Curing: heat and cu...

Embodiment 2

[0032] A treatment process for low-carbon steel-zinc-aluminum stainless steel composite material, comprising the following steps:

[0033] (1) Preparation of coating: first weigh a certain amount of high molecular polymer 8586, then add a certain amount of water to dilute to obtain high molecular polymer 8586 aqueous solution, the concentration of high molecular polymer 8586 aqueous solution is 75%, finally add titanium Powder and zinc powder, the mass percentage of zinc powder and titanium powder is 30%, the mass ratio of the mixture of titanium powder and zinc powder and high molecular polymer 8586 aqueous solution is 2.0: 2.0, stir to obtain coating;

[0034] (2) degreasing and derusting: degreasing and derusting the prepared steel sheet;

[0035] (3) Coating: the above-mentioned steel sheet after degreasing and derusting is wiped with filter paper to obtain a pretreated steel sheet, and the coating is applied on the pretreated steel sheet;

[0036] (4) Curing: heat and cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com