Preparation method of superfine silver powder for frontal silver slurry of photovoltaic cell

A photovoltaic cell and ultra-fine silver technology, applied in metal processing equipment, metal material coating technology, liquid chemical plating, etc., can solve the problems of weak force, no description of the preparation method of silver-coated graphene powder, etc., to achieve The effect of reducing voids, easy control of process conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

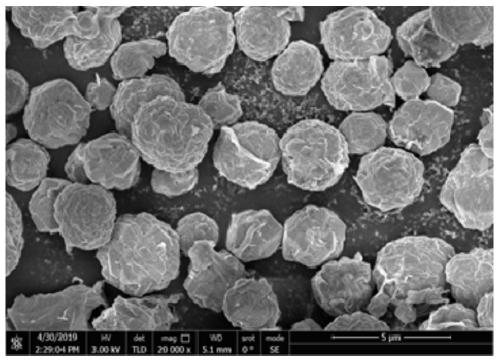

[0049] (1-1) Disperse 20mg of graphene oxide in 40mL of deionized water to make a concentration of 0.5g L -1 Graphene oxide dispersion, add 50mL of 1g·L -1 Silver nitrate solution (the mass ratio of graphene oxide and silver nitrate is 1:2.5), stirred, and centrifuged to obtain a solid.

[0050] (1-2) Disperse the obtained solid in 100mL of water, and slowly add 40mL of 4g·L after heating up to 90°C -1 Sodium borohydride solution, keep the reaction temperature constant, continue to react for 4 hours, stop heating, filter after cooling to room temperature, wash the filter cake with distilled water and ethanol, and finally dry to obtain graphene loaded with silver seeds.

[0051] (2-1) Disperse the obtained graphene loaded with silver seeds in 10 mL of deionized water to prepare a dispersion of graphene loaded with silver seeds.

[0052] (2-2) Add 10mL of 120g L to the graphene dispersion loaded with silver seeds -1 silver nitrate solution, heated to 90°C, stirred for 1 hour,...

Embodiment 2

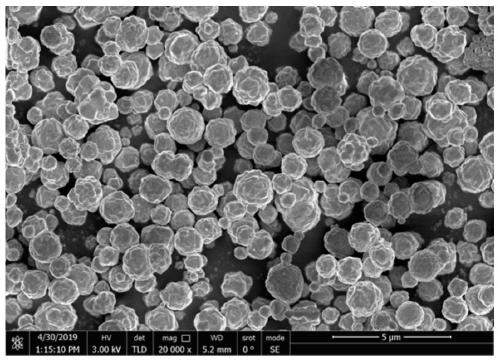

[0054] (1-1) Disperse 40mg graphene oxide in 100mL deionized water to make 0.4g L -1 Graphene oxide dispersion, add 80mL1.5g L -1 Silver nitrate solution, stirred, centrifuged.

[0055] (1-2) Disperse the obtained solid in 400mL of deionized water, and slowly add 120mL of 2g·L after heating up to 85°C -1 Sodium borohydride solution, keep the reaction temperature constant, continue to react for 4 hours, stop heating, filter after cooling to room temperature, wash the filter cake with distilled water and ethanol, and finally dry to obtain graphene loaded with silver seeds.

[0056] (2-1) The obtained graphene loaded with silver seeds was dispersed in 40 mL of deionized water to prepare a dispersion of graphene loaded with silver seeds.

[0057] (2-2) Add 10mL of 400g L to the graphene dispersion loaded with silver seeds -1 silver nitrate solution, heated to 85°C, stirred for 1 hour, then slowly added 70mL of 14g·L -1 The sodium borohydride solution, then continue to maintain...

Embodiment 3

[0059] (1-1) Disperse 30mg graphene oxide in 50mL deionized water to make 0.6g L -1 Graphene oxide dispersion, add 120mL0.5g L -1 Silver nitrate solution, stirred, centrifuged.

[0060] (1-2) Disperse the obtained solid in 90mL of deionized water, and slowly add 100mL of 3g·L after heating up to 80°C -1 Sodium borohydride solution, keep the reaction temperature constant, continue to react for 4 hours, stop heating, filter after cooling to room temperature, wash the filter cake with distilled water and ethanol, and finally dry to obtain silver-doped graphene oxide.

[0061] (2-1) The resulting graphene loaded with silver seeds was dispersed in 10 mL of deionized water to prepare a graphene dispersion loaded with silver seeds.

[0062] (2-2) Add 2.5mL of 300g L to the graphene dispersion loaded with silver seeds -1 silver nitrate solution, heated to 80°C, stirred for 1 hour, then slowly added 25mL of 10g·L -1 The sodium borohydride solution, then continue to maintain the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com