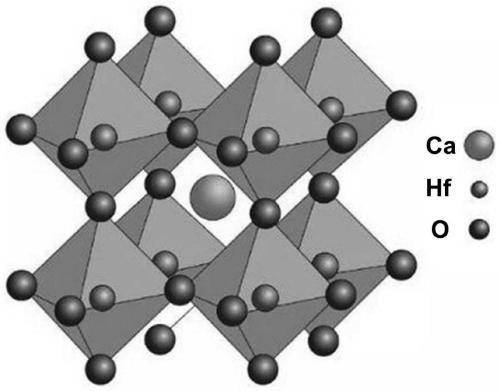

High-performance solid electrolyte and preparation method thereof

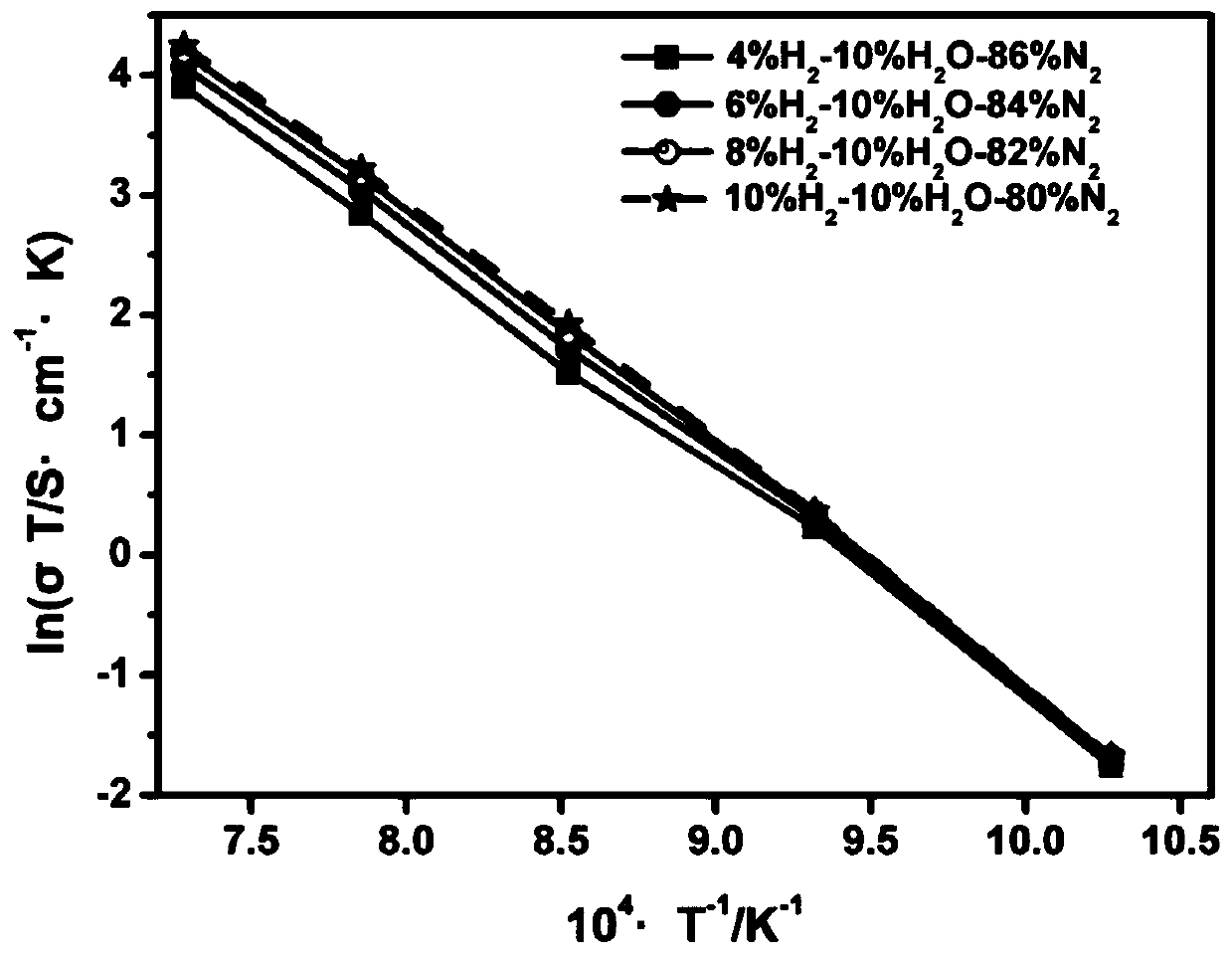

A solid electrolyte, high-performance technology, applied in the field of electrochemical materials, can solve the problems of poor chemical stability and high temperature stability, low electrolyte density, narrow proton conductivity range, etc., to achieve high corrosion resistance, good chemical stability, Effect of high temperature stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

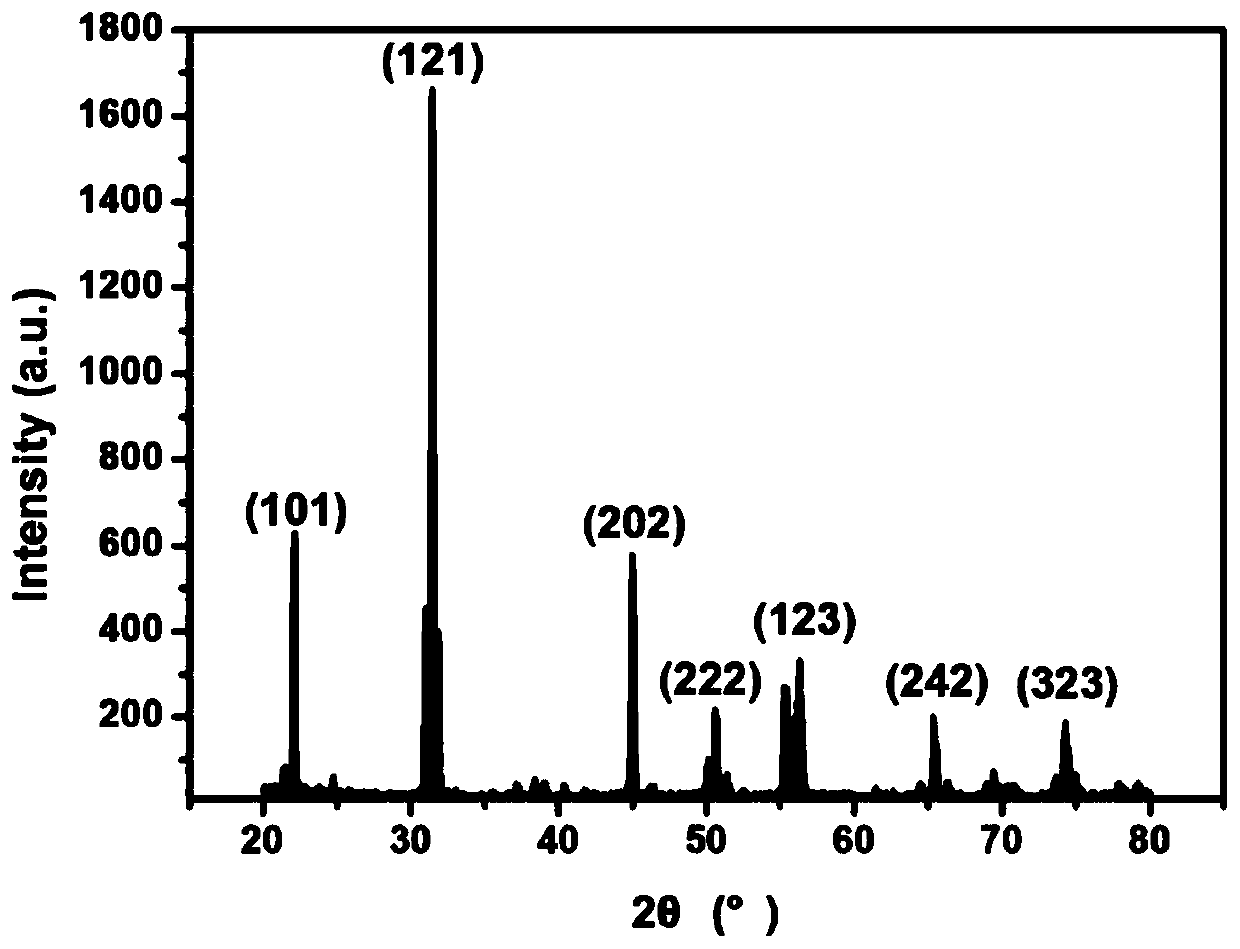

[0049] Weigh a certain amount of analytically pure CaCO 3 and rare earth oxide Sc 2 o 3 , placed in a corundum sagger with a cover, placed in a high-temperature furnace, raised to 500°C at a heating rate of 4°C / min, kept for 4 hours, and dried to dry the moisture in the raw material, then cooled to room temperature with the furnace, passed through agate The powder is obtained after mortar grinding. In addition, weigh a certain amount of analytically pure HfO 2Put it in a corundum sagger with a cover, put it into a high-temperature furnace, raise the temperature to 1100°C at a rate of 4°C / min, keep it warm for 4 hours, dry the moisture in the raw material, and perform high-temperature treatment on the raw material, and then cool it with the furnace After reaching room temperature, the powder was obtained after being ground in an agate mortar for later use.

[0050] CaCO in molar ratio 3 : Hf 2 o 3 : Sc 2 o 3 = The ratio of 20:9:1, weighed an appropriate amount of dried...

Embodiment 2

[0056] Weigh a certain amount of analytically pure CaCO 3 and rare earth oxide Lu 2 o 3 , respectively placed in a corundum sagger with a cover, placed in a high-temperature furnace, raised to 600°C at a heating rate of 5°C / min, kept for 5 hours, and dried to dry the moisture in the raw material, then cooled to room temperature with the furnace, and passed through agate The powder is obtained after mortar grinding. In addition, weigh a certain amount of analytically pure HfO 2 Put it in a corundum sagger with a cover, put it into a high-temperature furnace, raise the temperature to 1200°C at a heating rate of 5°C / min, keep it warm for 5 hours, dry the moisture in the raw material, and perform high-temperature treatment on the raw material, and then cool it with the furnace After reaching room temperature, the powder was obtained after being ground in an agate mortar for later use.

[0057] CaCO in molar ratio 3 : Hf 2 o 3 : Lu 2 o 3 = The ratio of 20:8.5:1.5, take an ...

Embodiment 3

[0063] Weigh a certain amount of analytically pure CaCO 3 and rare earth oxide Yb 2 o 3 , respectively placed in a corundum sagger with a cover, placed in a high-temperature furnace, raised to 700°C at a heating rate of 6°C / min, kept for 4 hours, and dried to dry the moisture in the raw material, then cooled to room temperature with the furnace, and passed through agate The powder is obtained after mortar grinding. In addition, weigh a certain amount of analytically pure HfO 2 Put it in a corundum sagger with a cover, put it into a high-temperature furnace, raise the temperature to 1200°C at a heating rate of 6°C / min, keep it warm for 6 hours, dry the moisture in the raw material, and perform high-temperature treatment on the raw material, and then cool with the furnace After reaching room temperature, the powder was obtained after being ground in an agate mortar for later use.

[0064] CaCO in molar ratio 3 : Hf 2 o 3 : Yb 2 o 3 = The ratio of 20:8:2, take an appropr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com