Method for extracting aluminum

An extraction method, high-aluminum fly ash technology, applied in the field of aluminum extraction, can solve the problems of large alkali circulation volume and high causticity of sodium aluminate crude liquid, and achieve high efficiency, energy consumption, high extraction efficiency, and lower impregnation temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

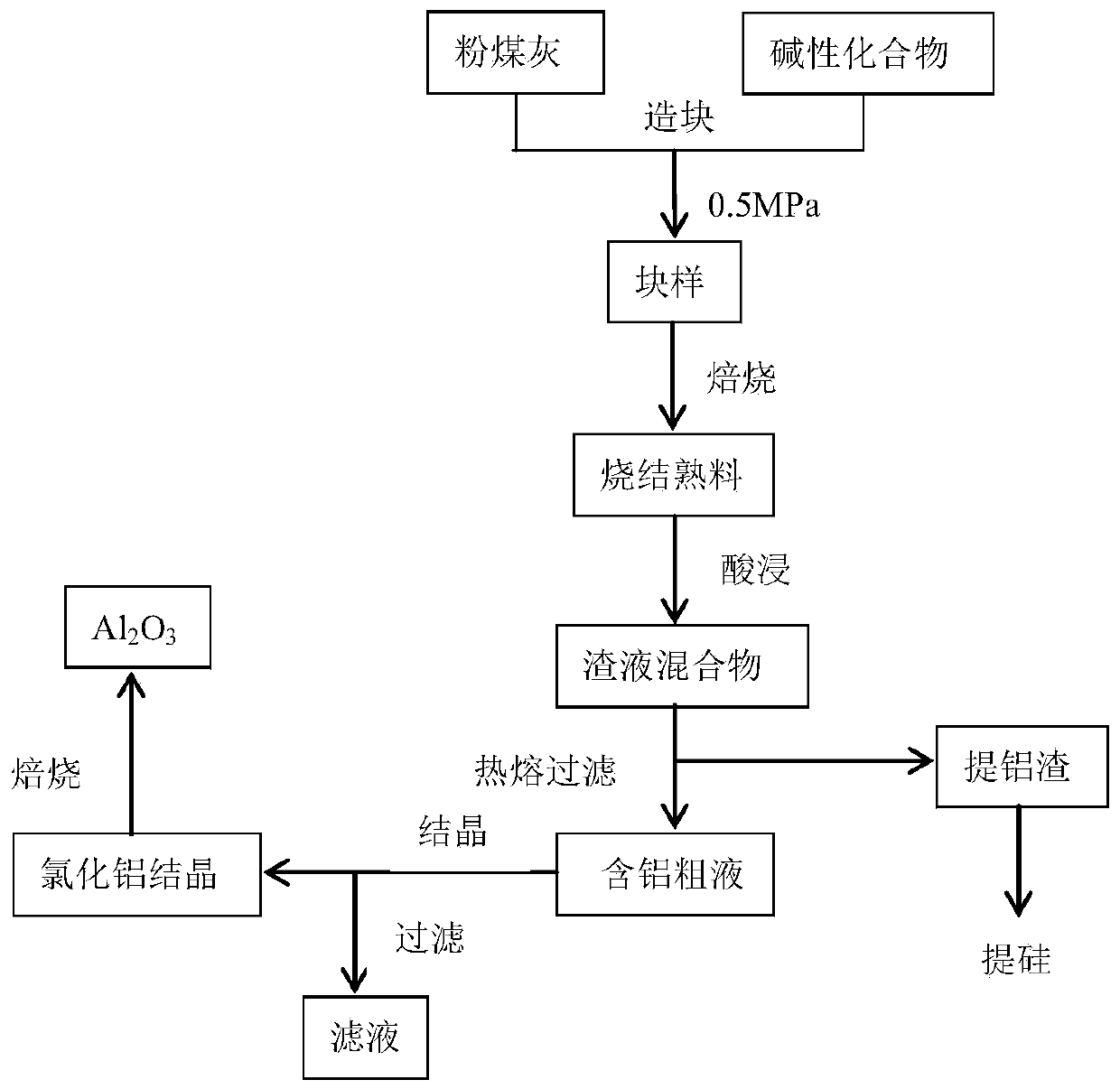

Method used

Image

Examples

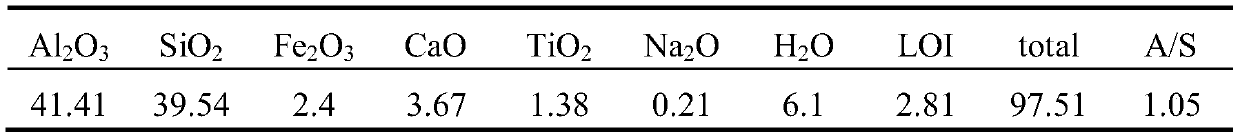

Embodiment 1

[0028] The invention discloses an aluminum extraction method, which adopts basic compound and fly ash to form, roasts, and then acid leaches the sintered sample block to obtain aluminum-containing crude liquid; the basic compound is sodium hydroxide; the basic compound and powder The mass ratio of coal ash is 0.8; the molding and roasting process is as follows: after the dried fly ash and the basic compound are ground and mixed in proportion, under 0.5MPa, continue for 1min, and the specification of the compacted green body is a cylinder (20.0mm ×10.0mm), then put into a muffle furnace and heat to a certain temperature and constant temperature for a period of time, then cool to obtain sintered clinker; the certain temperature is 825°C; the constant temperature time is 150min; the acid leaching process is : Grinding the sintered clinker, mixing and stirring with 3mol / L sulfuric acid in proportion to leaching, suction filtration, washing the filter residue with water, and separat...

Embodiment 2

[0030] The invention discloses an aluminum extraction method, which adopts basic compound and fly ash to form, roasts, and then acid leaches the sintered sample block to obtain aluminum-containing crude liquid; the basic compound is sodium hydroxide; the basic compound and powder The mass ratio of coal ash is 1.5; the molding and roasting process is as follows: after drying the fly ash and the basic compound are ground and mixed in proportion, under 0.5MPa, continue for 1min, and the compacted green body specification is a cylinder (20.0mm ×10.0mm), then put into a muffle furnace and heat to a certain temperature and constant temperature for a period of time, then cool to obtain sintered clinker; the certain temperature is 825°C; the constant temperature time is 150min; the acid leaching process is : Grinding the sintered clinker, mixing and stirring with 3mol / L sulfuric acid in proportion to leaching, suction filtration, washing the filter residue with water, and separation by...

Embodiment 3

[0032] The invention discloses an aluminum extraction method, which adopts basic compound and fly ash to form, roasts, and then acid leaches the sintered sample block to obtain aluminum-containing crude liquid; the basic compound is sodium hydroxide; the basic compound and powder The mass ratio of coal ash is 0.5; the molding and roasting process is as follows: after the dried fly ash and the basic compound are ground and mixed in proportion, under 0.5MPa, continue for 1min, and the specification of the compacted green body is a cylinder (20.0mm ×10.0mm), then put into a muffle furnace and heat to a certain temperature and constant temperature for a period of time, then cool to obtain sintered clinker; the certain temperature is 825°C; the constant temperature time is 150min; the acid leaching process is : Grinding the sintered clinker, mixing and stirring with 3mol / L sulfuric acid in proportion to leaching, suction filtration, washing the filter residue with water, and separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com