A steel energy-saving fireproof window and its manufacturing process

A fire-resistant window and steel technology, which is applied to fire-resistant doors, windows/doors, door/window accessories, etc., can solve problems such as affecting air circulation, inner leaves cannot be opened, and cannot play a role in fire prevention, so as to ensure normal operation, Good drainage effect, the effect of curbing the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

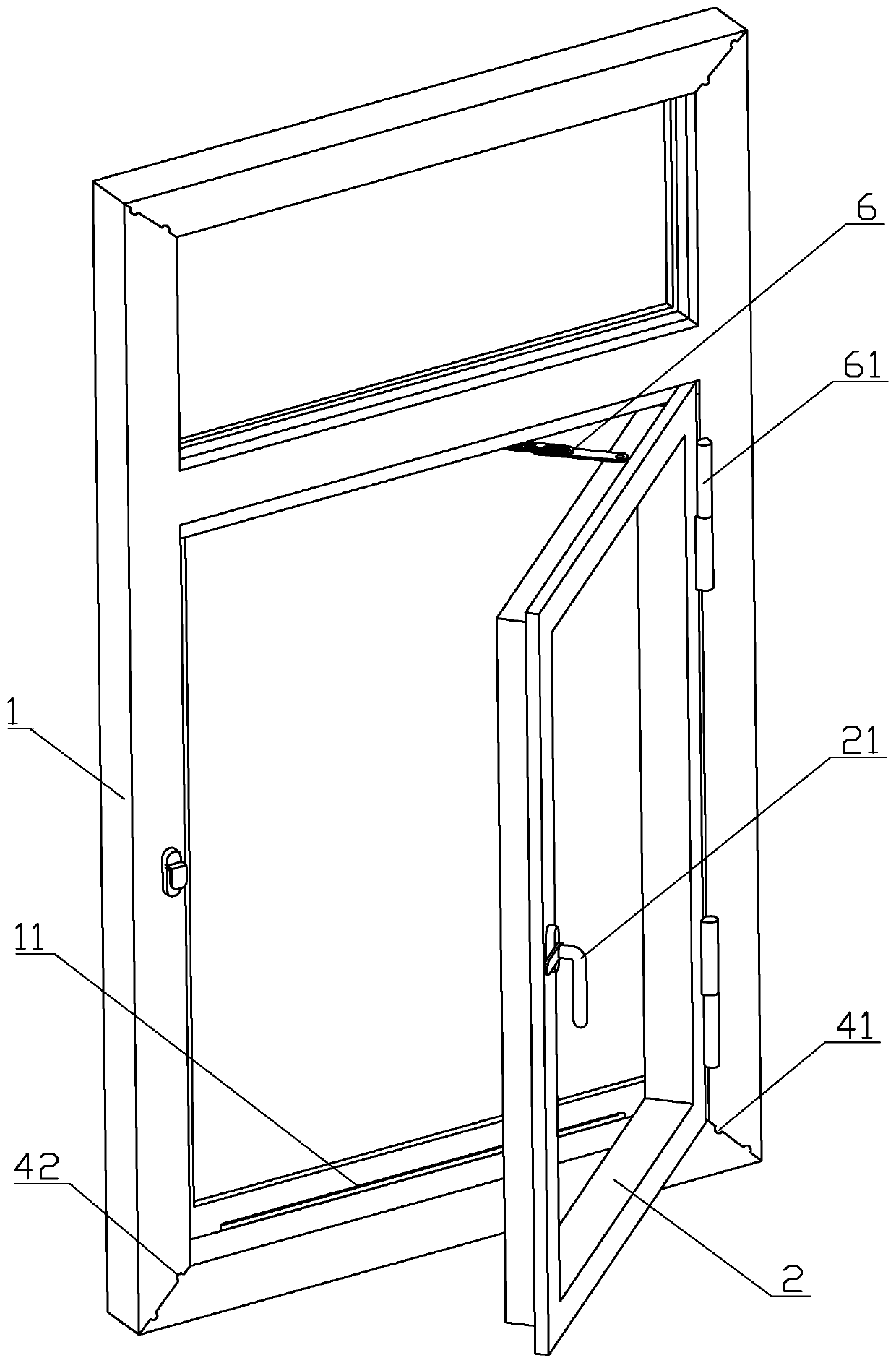

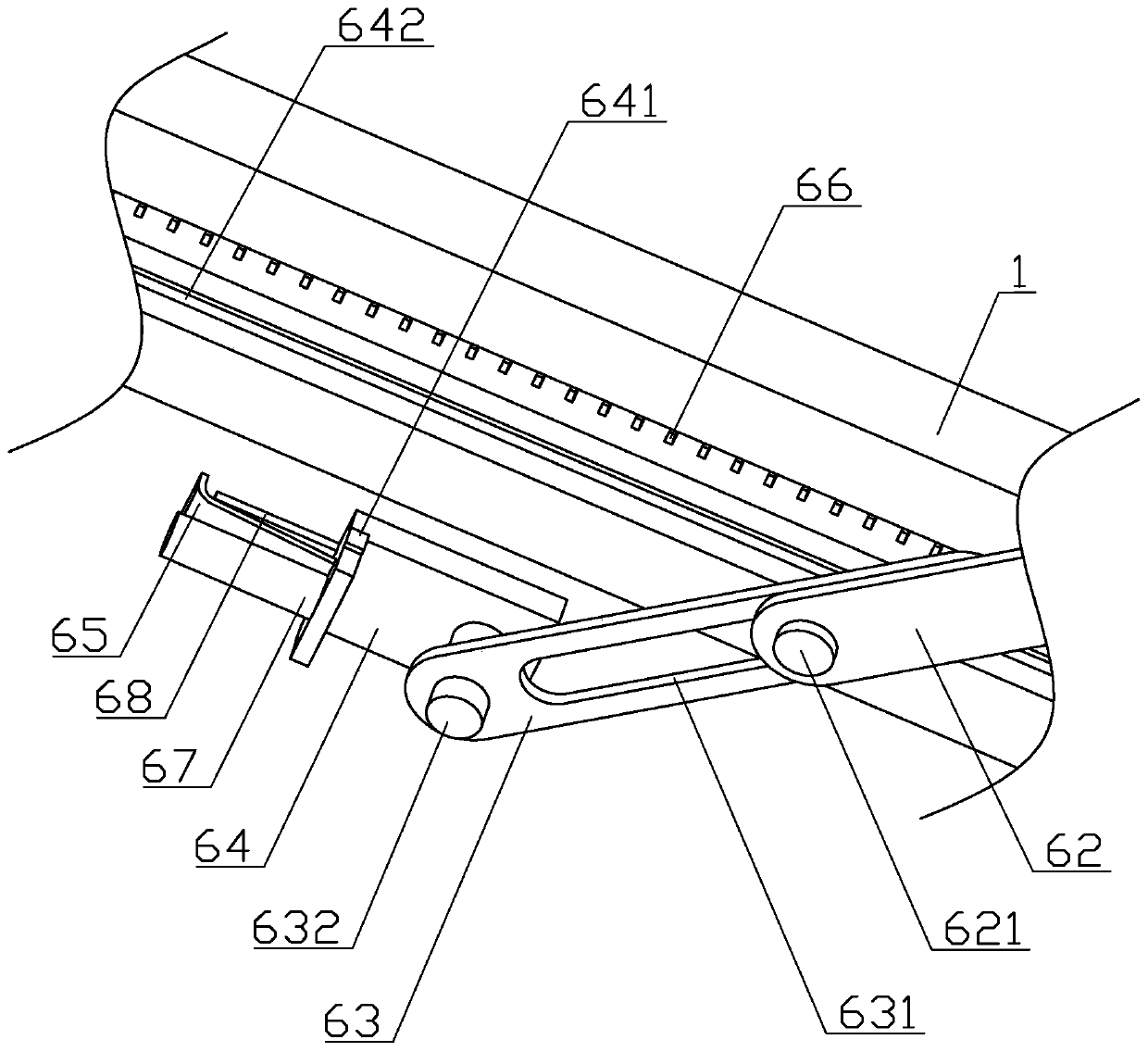

[0047] Embodiment 1: as figure 1 As shown, a steel energy-saving fireproof window includes an outer frame 1 and an inner fan 2, both of which are rectangular closed frames surrounded by a plurality of frame profiles, and one side of the inner fan 2 is hinged to the outer frame 1. A semicircular groove 42 and a semicircular block 41 are provided on the edge of each frame profile, and the semicircular groove 42 and the semicircular block 41 between two adjacent frame profiles are spliced and matched with each other.

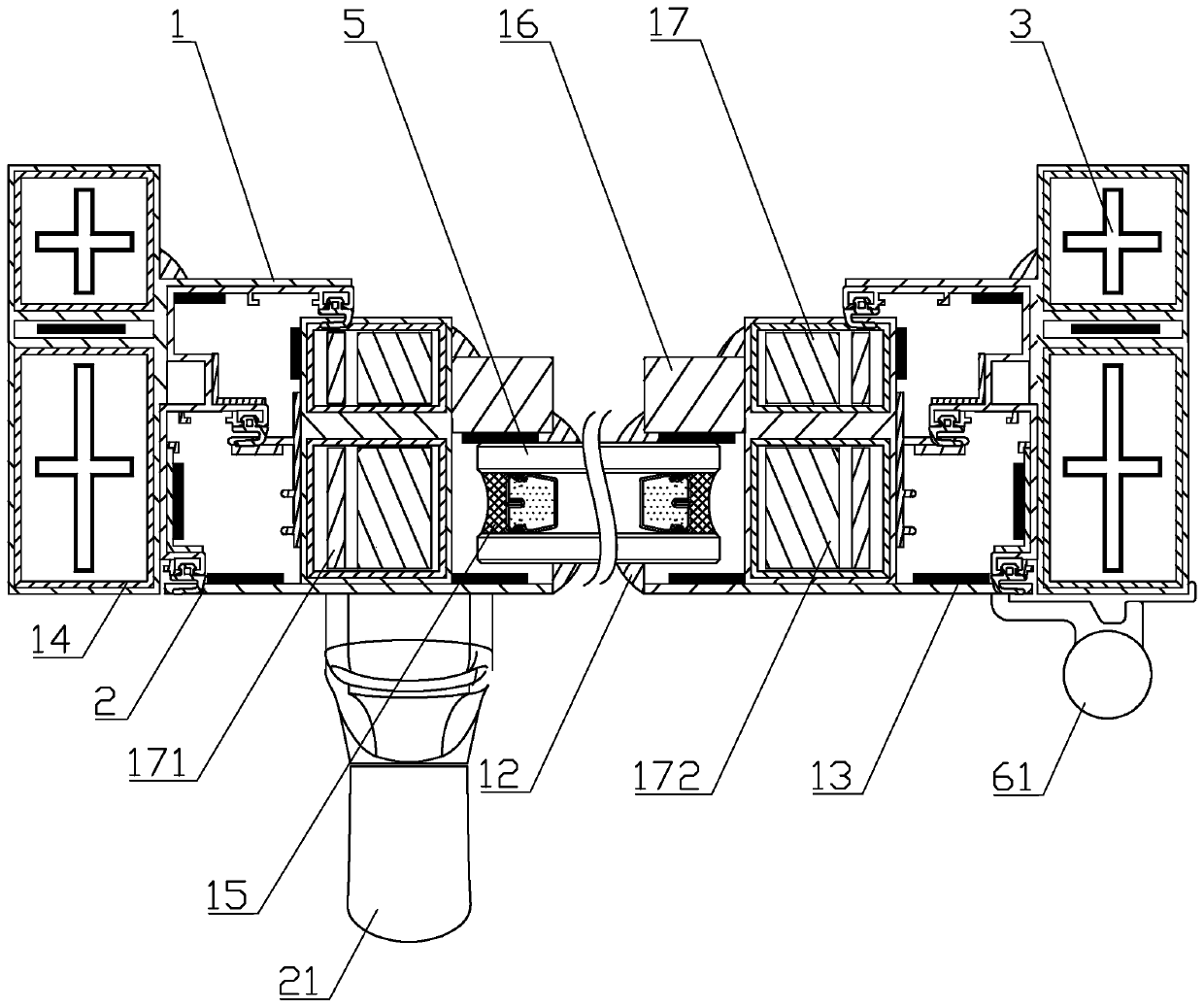

[0048] like figure 1 , figure 2 As shown, double-layer glass 5 is installed on the inner fan 2, glass bead 16 is fixed on the surface of the inner side frame profile of the inner fan 2, and a flame-retardant spacer 15 is fixed on the edge of the double-layer glass 5, between the glass bead 16 and the double-layer glass 5 The space is filled with weather-resistant glue 12. Weathering Adhesive 12 is a sealant that has passed the artificial accelerated weatherin...

Embodiment 2

[0055] Embodiment 2: as Figure 1-4 Shown, a kind of manufacturing method of steel energy-saving fireproof window, comprises the following steps:

[0056] S1. Profile processing: according to the size of the required fire window, cut the structure of each part, and then perform slotting and drilling operations;

[0057] S2. Assembling internal parts: First, use refractory glue to stick perlite 14 on the inner wall of the frame profile, and then fill the prepared waterproof board 171, steel plate 172, sliding seat 31 and cross column 3 into the inner fan 2 and the outer frame in sequence In each cavity 17 of the frame profile of 1, a complete inner fan 2 and outer frame 1 are assembled;

[0058] Among them, the sliding seat 31 and the cross column 3 need to be assembled first and then filled into the cavity 17 in the frame profile of the inner fan 2 and the outer frame 1, and the assembling process is as follows:

[0059] a. First, install a sliding seat 31 on one end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com