A double-sided plasma processing system for capacitor film materials

A capacitor film and plasma technology, applied in plasma, capacitor, capacitor manufacturing, etc., can solve the problems of inability to handle both sides of capacitor film materials, unfavorable large-scale industrial production application, complex process, etc., to achieve mass production, The effect of reducing the surface energy of the material and simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

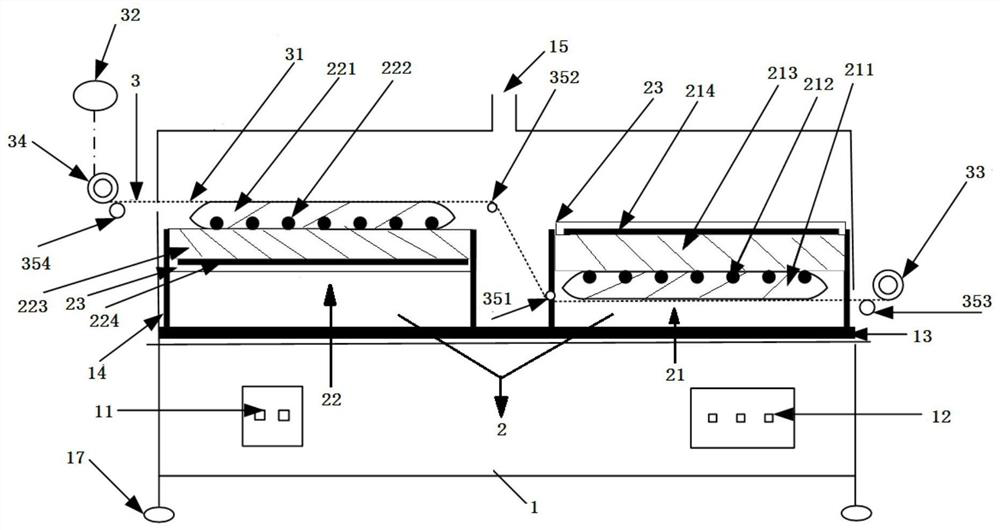

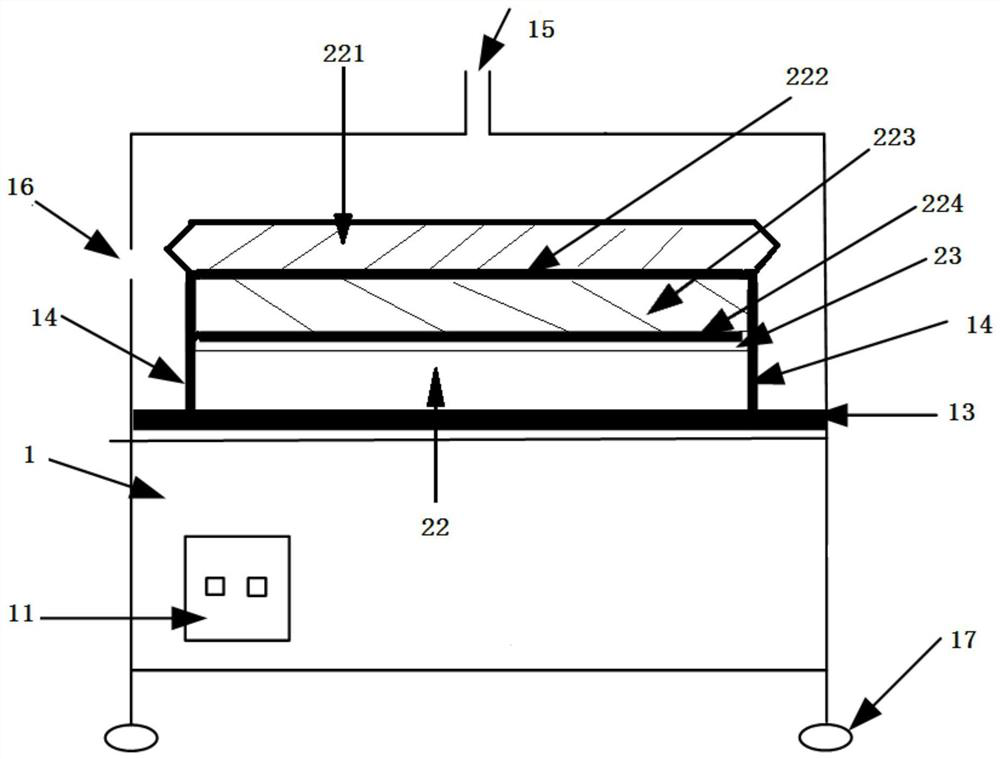

[0052] This embodiment discloses the structure of a system for treating both sides of a capacitor film material by surface dielectric barrier discharge.

[0053] see figure 1 , the housing 1 and the plasma processing device 2, wherein the plasma processing device 2 includes a first plasma processing unit 21 and a second plasma processing unit 22, which are sequentially arranged at intervals along the transmission direction of the capacitor film material 31 Inside the casing 1; the first plasma processing unit 21 includes a first barrier dielectric layer 213, a first plasma generation layer 211 disposed on its lower side and a first ground electrode 214 disposed on its upper side, the first The second plasma processing unit 22 includes a second blocking dielectric layer 223 , a second plasma generation layer 221 disposed on its upper side, and a second ground electrode 224 disposed on its lower side.

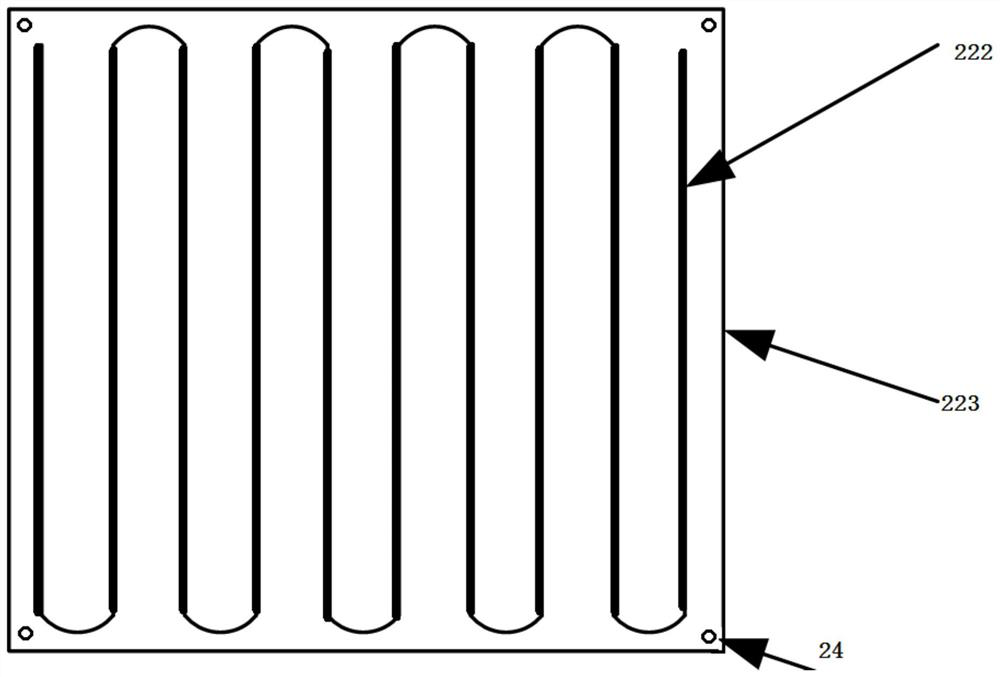

[0054] see image 3 , a plurality of second high-voltage electrodes 222 ar...

Embodiment 2

[0074] This embodiment discloses the method of processing capacitor thin film materials in embodiment 1.

[0075] see figure 1 , the power supply 11 provides high-voltage electricity to the first high-voltage electrode 212 and the second high-voltage electrode 222, and generates atmospheric pressure low-temperature plasma on their surfaces; the motor 32 drives the winding roller 34 to rotate, and cooperates with the fourth conductive roller shaft 354 for winding Capacitor film material 31, makes release material roller 33 cooperate the 3rd conduction roller shaft 353 to discharge capacitor film material 31, capacitor film material 31 advances along the fixed route of conduction roller shaft; figure 2 , the precursor and the working gas are introduced into the air inlet 16, and the precursor is respectively attached to the two faces of the capacitor film material 31, and when passing through the first plasma generation layer 211 and the second plasma generation layer 221, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com