Self-generated type steam protection and fire extinguishing process

A steam and self-generated technology, applied in fire rescue, etc., can solve the problems of affecting the service life of the furnace body, high cost of foam fire extinguishing and nitrogen fire extinguishing, complex equipment, etc., and achieves the effects of simple structure, rapid cooling and fire extinguishing, and fast water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

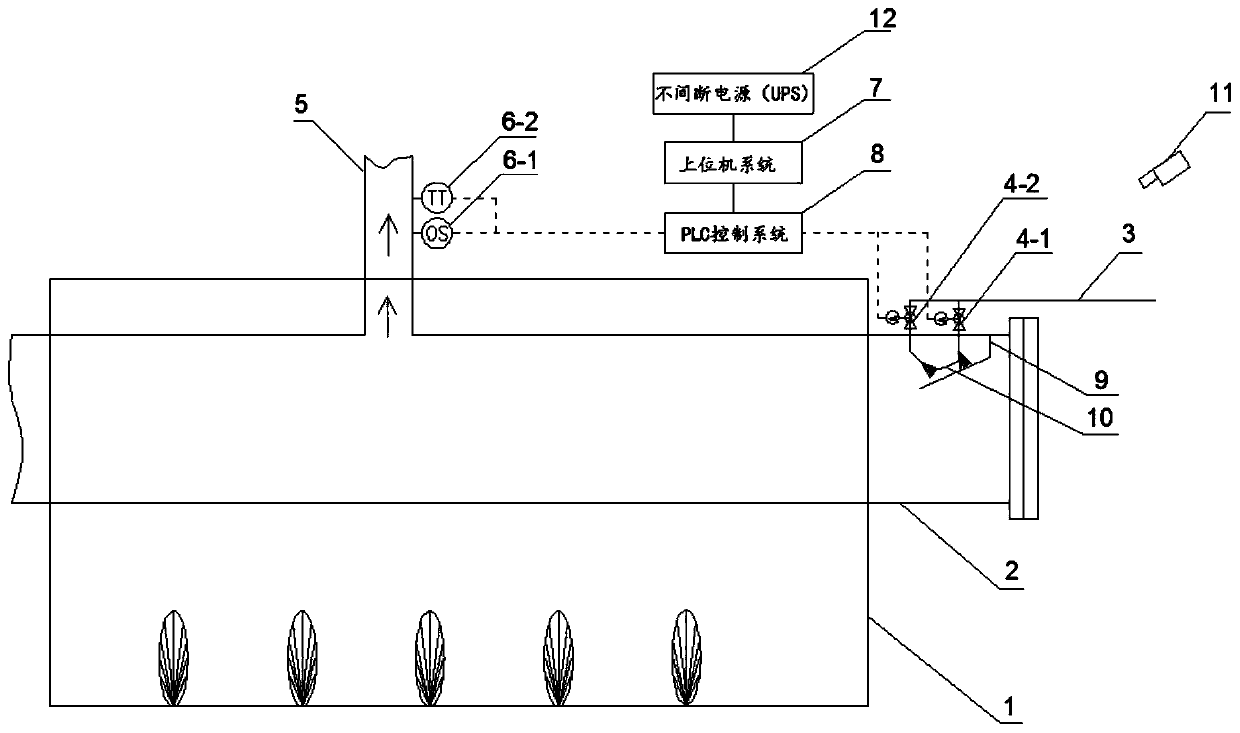

[0027] Embodiment one, such as figure 1 As shown, a self-generating steam protection and fire extinguishing technology includes: after the remote monitoring system detects a fire in the reaction chamber 2, the upper computer system 7 and the PLC control system 8 are remotely operated to control the action of the explosion-proof solenoid valve, and the water source passes through the reaction chamber. 2. The atomizing nozzle 10 in the reaction chamber 2 is sprayed in the form of water mist onto the inner partition 9 of the reaction chamber 2. The amount of spraying water can be controlled by detecting the oxygen content and temperature in the reaction chamber 2. At the same time, the upper computer system 7 and the PLC system The amount of spraying water can be chain-controlled according to the oxygen content and an alarm message can be issued, and the power supply of the whole control system is powered by the uninterruptible power supply 12 .

[0028] The water mist is sprayed...

Embodiment 2

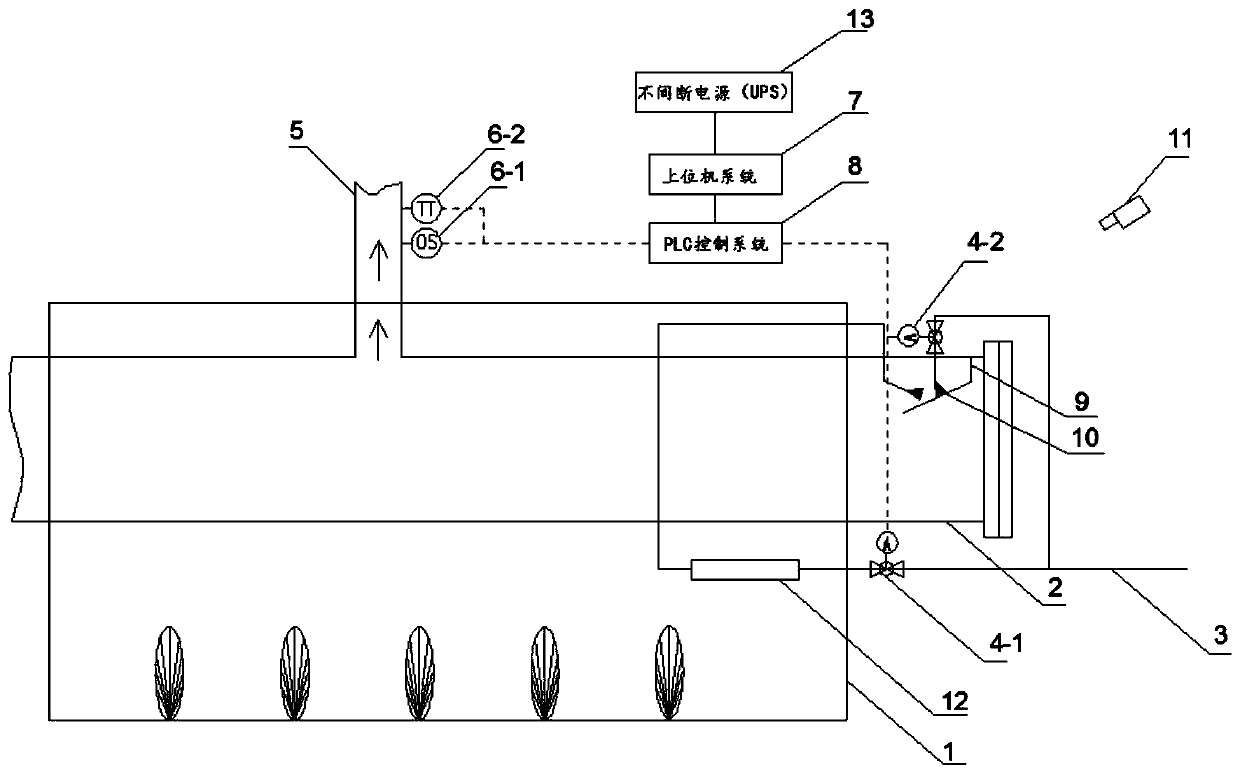

[0033] Embodiment two, such as figure 2 As shown, a self-generating steam protection and fire extinguishing technology includes: after the remote monitoring system detects a fire in the reaction chamber 2, the upper computer system 7 and the PLC control system 8 are remotely operated to control the action of the explosion-proof solenoid valve, and the water source passes through the reaction chamber. 2. The atomizing nozzle 10 in the reaction chamber 2 is sprayed in the form of water mist onto the inner partition 9 of the reaction chamber 2. The amount of spraying water can be controlled by detecting the oxygen content and temperature in the reaction chamber 2. At the same time, the upper computer system 7 and the PLC system The amount of spraying water can be chain-controlled according to the oxygen content and an alarm message can be sent, and the power supply of the whole control system is powered by the uninterruptible power supply 13 .

[0034] The water mist is sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com