An anaerobic dynamic membrane reactor for efficient treatment of refractory wastewater

A technology for treating wastewater and reactors, applied in anaerobic digestion treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Treatment cost, efficiency improvement, and efficient treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

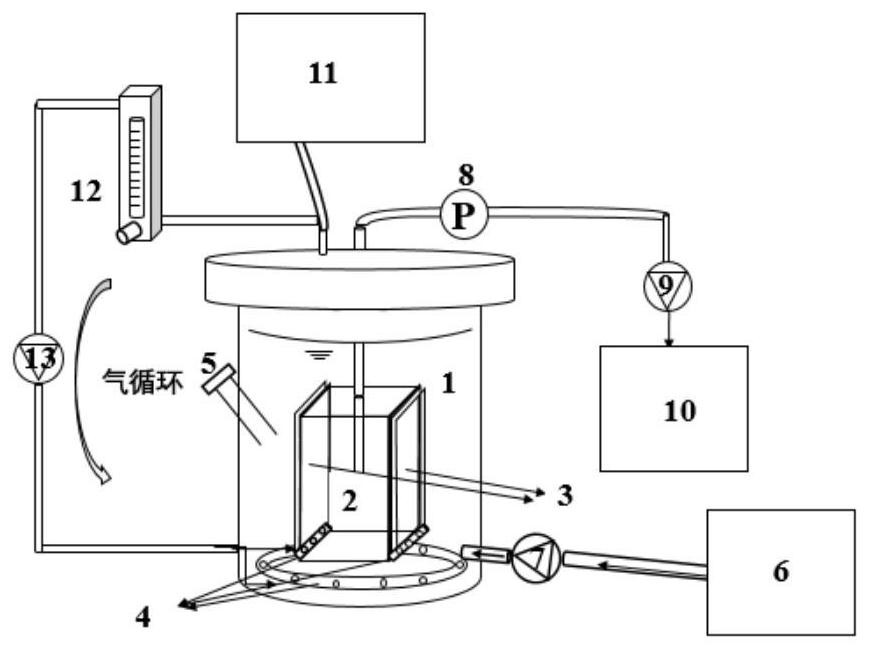

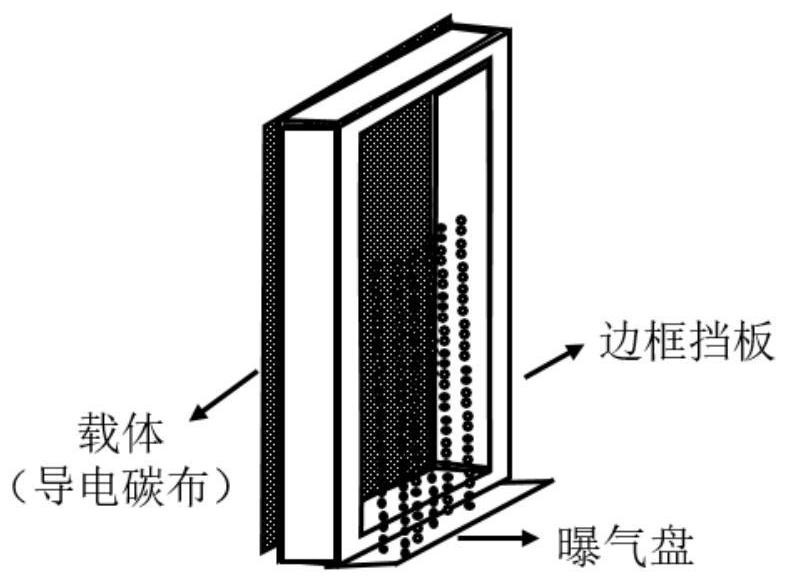

Method used

Image

Examples

Embodiment 1

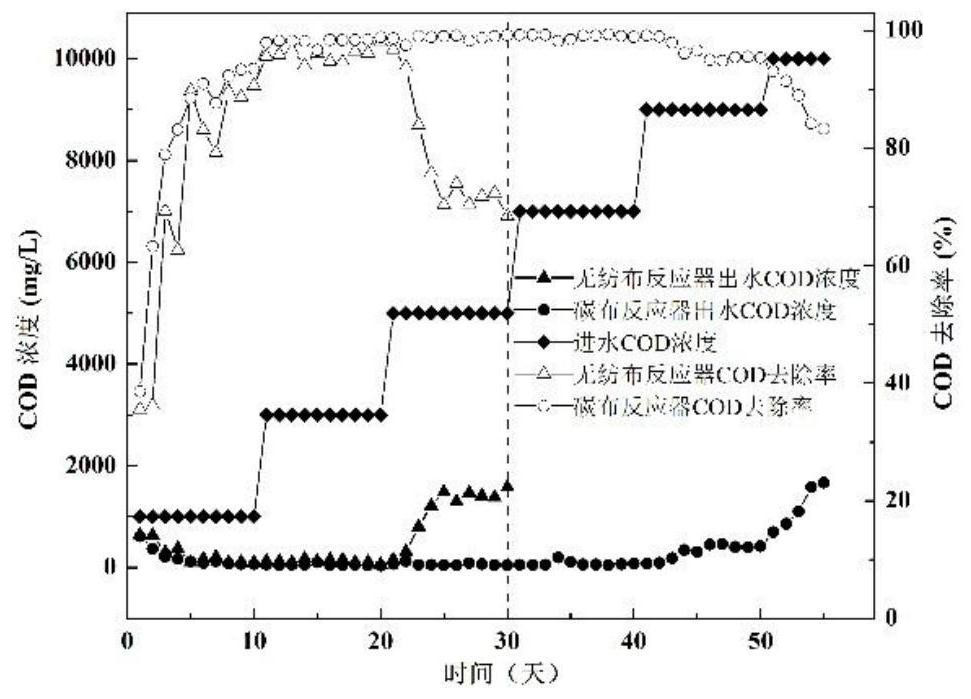

[0038] The reactor feed water is brewery simulated wastewater (COD 1000mg / L-10000mg / L), and the initial COD concentration of the reactor is 1000mg / L for anaerobic mud acclimatization. The acclimatization period runs for a total of 12 days, and the effluent COD concentration is stable <100mg / L After L, it enters the filtration stage. During the filtration period, the concentration of COD in the influent water is 1000mg / L, and then continuously increases to 3000mg / L, 5000mg / L, 7000mg / L, 9000mg / L, and finally increases to 10000mg / L; each load runs for 10 days . The anaerobic dynamic membrane reactor with non-woven fabric as the carrier experienced acidification collapse when the COD concentration increased to 5000mg / L, while the reactor with conductive carbon cloth as the carrier operated stably until the COD concentration increased to 10000mg / L, and the operation was stable The COD removal rate was stable above 95% in the first stage, and the SS removal rate was stable above 90%...

Embodiment 2

[0040] The reactor feed water is waste incineration leachate (COD 3000mg / L-23000mg / L), and the initial reactor feed water is the effluent COD of diluted waste incineration leachate (COD 3000mg / L) treated by anaerobic methanogenesis The concentration is stable <100mg / L, and it has been running for 22 days. After entering the filtration stage, the reactor with carbon cloth as the carrier continuously increases the concentration of influent COD from 3000mg / L to 5000mg / L, 7000mg / L, 9000mg / L, and finally to 23000mg / L; each load runs 10 days, and the whole stage runs for 93 days in total. The COD removal rate is stable above 90% in the stable period, and the SS removal rate is stable above 90% in the whole stage. However, the reactor with non-woven fabric as the carrier will collapse when the influent water increases to 18000 mg / L. The anaerobic dynamic membrane reactor strengthened by conductive carbon cloth improved the treatment efficiency of waste incineration leachate by 27.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com