Modification method of granular carbon material for anaerobic digestion of low-concentration wastewater

An anaerobic digestion and granular carbon technology, applied in anaerobic digestion treatment, chemical instruments and methods, granular microbial carrier treatment, etc., can solve the problems of reduced specific surface area, complicated preparation methods, etc. Ease of implementation and effect with few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

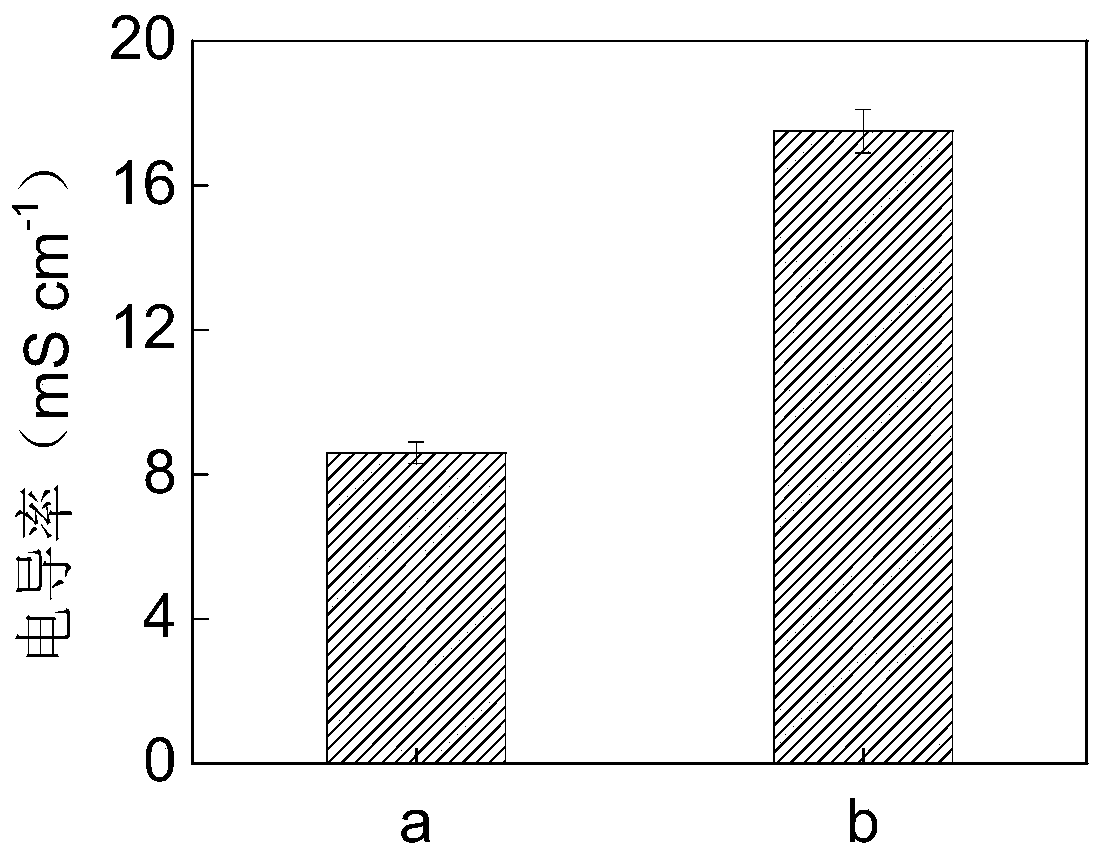

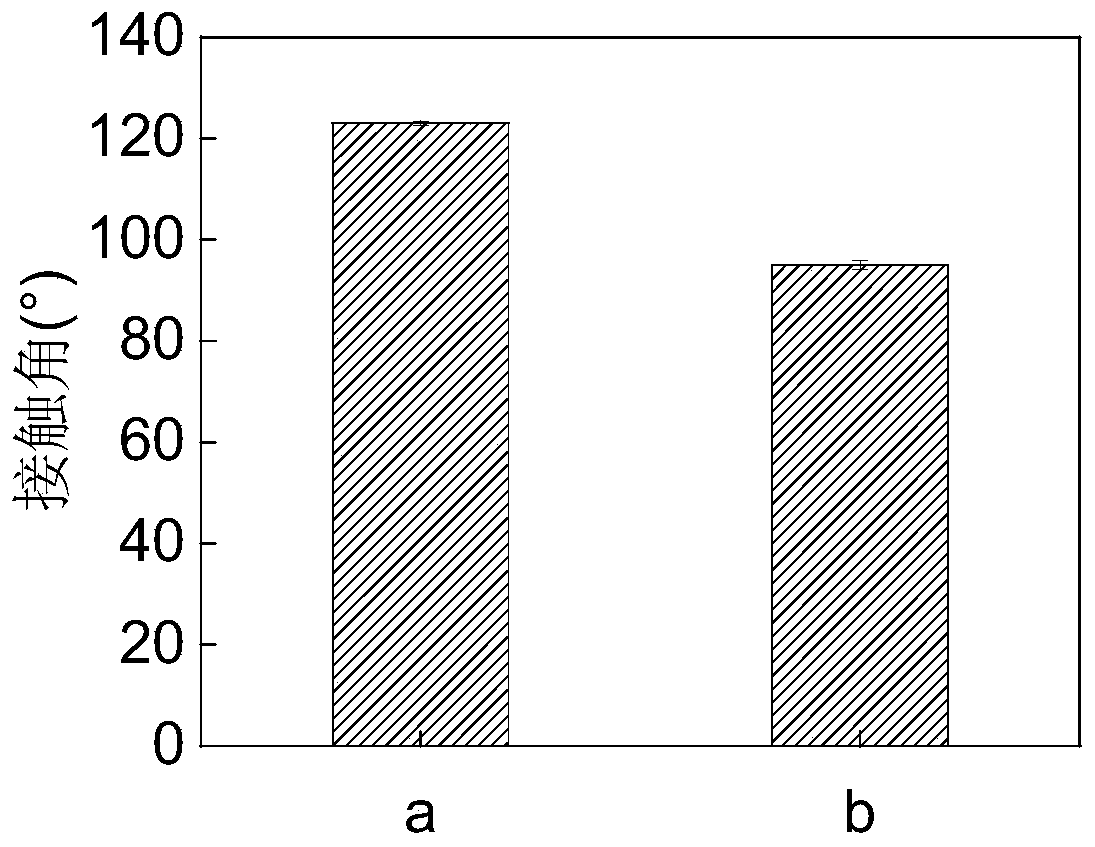

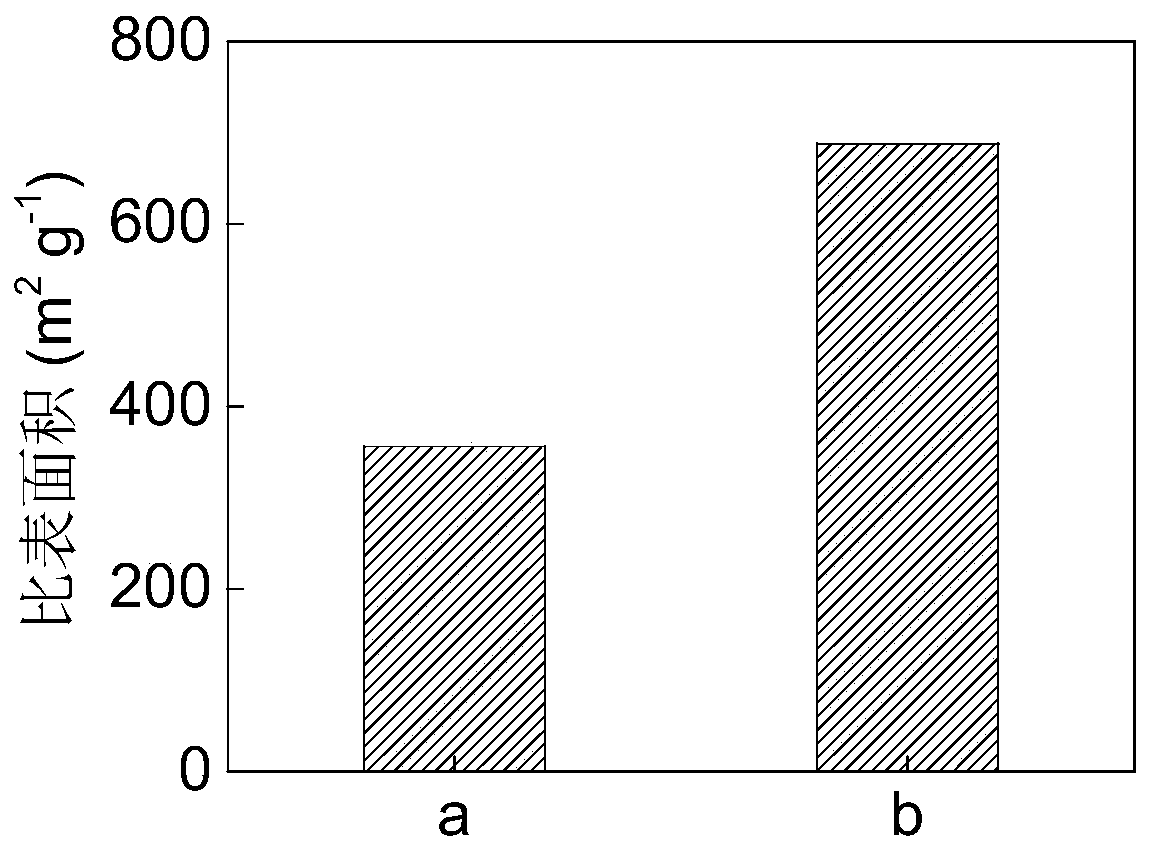

[0018] Specific Embodiment 1: This embodiment is a method for modifying granular carbon materials used for anaerobic digestion of low-concentration wastewater. Specifically, it is completed in the following steps: dissolve iron salt and ferrous salt in a solvent, and first add For the granular carbon material, add an oxidizing agent after stirring and mixing, carry out co-precipitation reaction, wash the solid matter obtained by the co-precipitation, obtain the solid matter after washing, and dry the solid matter after washing to obtain the modified granular carbon material;

[0019] The molar ratio of the iron salt to the ferrous salt is 6:(1~6), the volume ratio of the amount of the substance of the iron salt to the solvent is 1mol:96mL~6153mL; the molar ratio of the iron salt to the granular carbon material The ratio is 1:(5-15), the molar ratio of the iron salt to the oxidant is 1:(5-40); the particle size of the granular carbon material is 10-30 mesh.

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the iron salt is ferric chloride or ferric nitrate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the ferrous salt is ferrous chloride, ferrous nitrate or ferrous sulfate. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com