Improved backwashing device for biofilter and application of backwashing device in backwashing of biofilter

A biological filter and backwashing technology, which is applied to biological treatment devices, biological water/sewage treatment, granular microbial carrier treatment, etc., can solve the problem of increasing head of water inlet pump and backwashing water pump, increasing equipment investment and operating costs, and equipment Problems such as the increase of the selection pressure level can achieve the effect of saving equipment and civil engineering costs, saving backwash water and energy consumption, and reducing equipment and civil engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

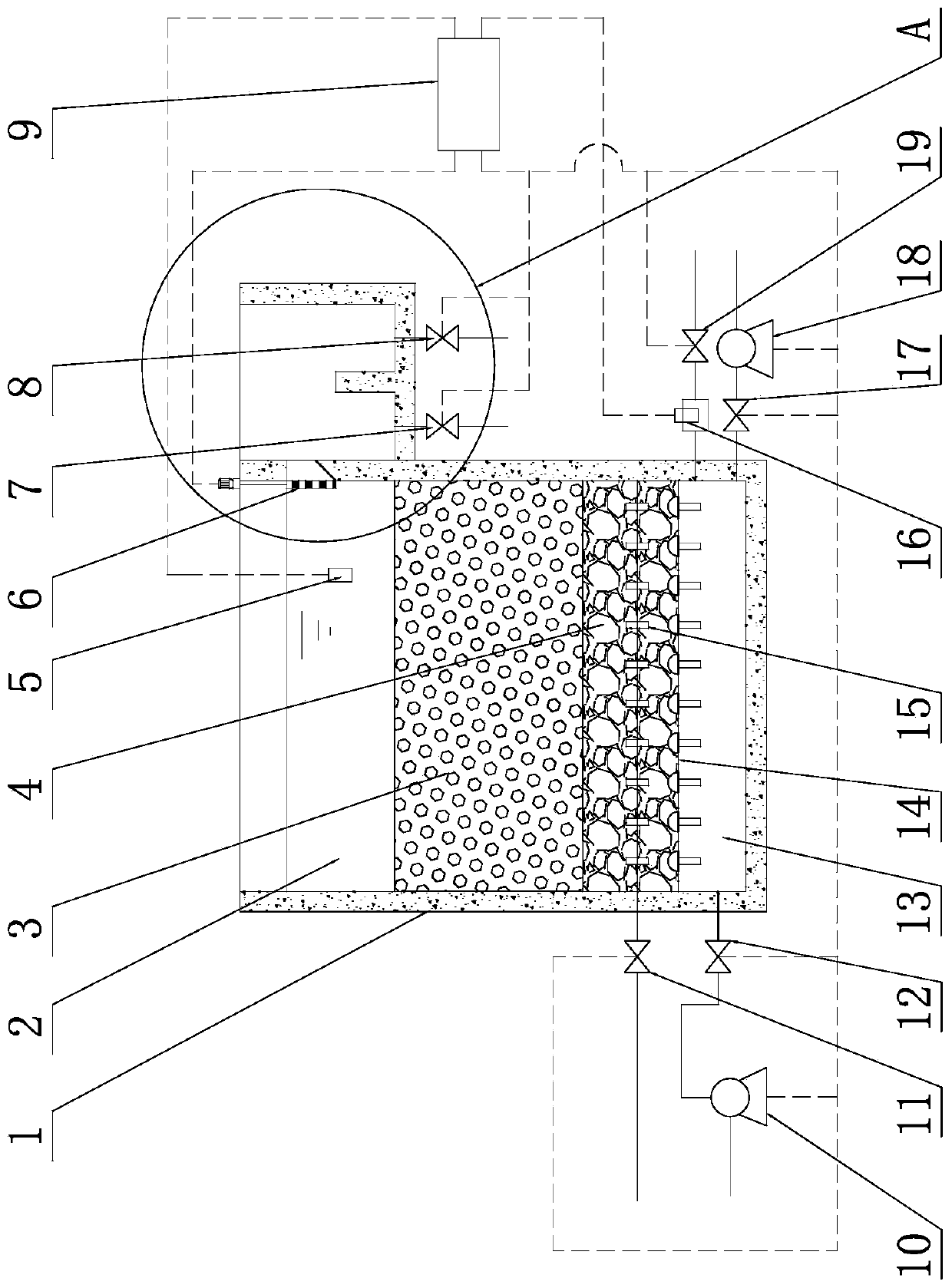

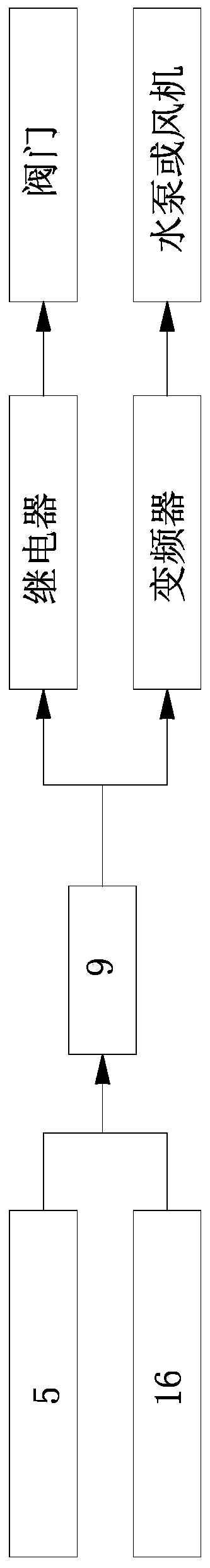

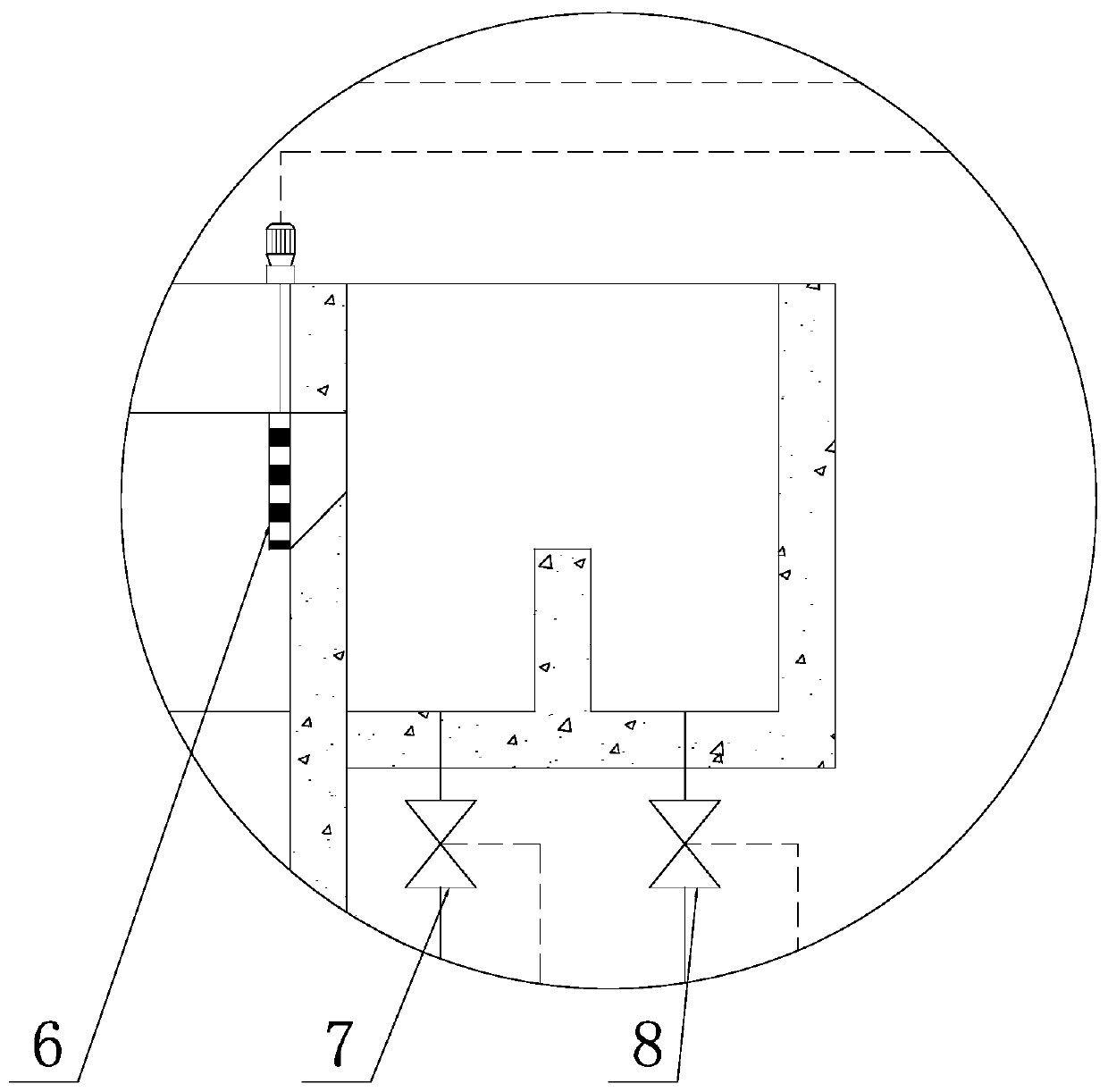

[0065] This embodiment is applied to the nitrification aerated biological filter in the biological filter, and its overall structure is shown in the figure, wherein the backwashing device of the improved biological filter includes a biological filter 1, and the biological filter 1 is sequentially arranged from bottom to top There are buffer water distribution area 13, filter plate 14, support layer 4, filter material layer 3, clean water area 2, support layer 4 is sandwiched between filter material layer 3 and filter plate 14, backwashing air intake pipeline, water inlet pipe The input ends of the backwash water inlet pipeline and the backwash water inlet pipeline are respectively connected to the buffer water distribution area 13, and the backwash water outlet in the clean water area 2 is connected to the drainage pipeline. Gas pipeline, backwash air intake pipeline, water inlet pipeline, drainage pipeline, pumping device in backwash water inlet pipeline, backwash drainage pip...

Embodiment 2

[0070] The application of the backwashing device of the improved biofilter in the present embodiment in the backwash of the biofilter is as follows:

[0071] Adopt the backwashing device of the improved biofilter among the embodiment 1, the treatment water capacity is 500 liters / hour, and the height of clear water area is 0.7 meter, and filter screen aperture is 90% of biological filter material particle diameter, comprises the following steps:

[0072] A. Information collection and backwash frequency setting

[0073] When the biological filter sewage treatment system is in operation, the sewage enters the bottom of the biological filter 1 through the water inlet pipeline, the water inlet pressure sensor 16 and the water inlet valve 19, and the air enters the biological filter 1 through the inlet pipeline, the inlet valve 11 and the air aerator 15. At the bottom of the filter tank 1, the control device 9 collects the water inlet pressure, running time and water outlet turbidit...

Embodiment 3

[0082] The application of the backwashing device of the improved biofilter in the present embodiment in the backwash of the biofilter is as follows:

[0083] Adopt the backwashing device of the improved biofilter in embodiment 1, the treatment water volume is 500 liters / hour, and the height of clear water area is 0.5 meter, and filter screen aperture is 70% of biological filter material particle diameter, comprises the following steps:

[0084] A. Information collection and backwash frequency setting

[0085] When the biological filter sewage treatment system is in operation, the sewage enters the bottom of the biological filter 1 through the water inlet pipeline, the water inlet pressure sensor 16 and the water inlet valve 19, and the air enters the biological filter 1 through the inlet pipeline, the inlet valve 11 and the air aerator 15. At the bottom of the filter tank 1, the control device 9 collects the water inlet pressure, running time and water outlet turbidity signals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com