A preparation method of high-strength and high-toughness boron carbide-based ceramic material and ceramic material thereof

A high-toughness boron carbide-based, ceramic material technology, applied in the field of ceramic materials, can solve the problems of increased cost, decreased material performance, decreased hardness, etc., and achieves the effects of reducing costs, inhibiting excessive growth, and reducing raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention uses industrially produced boron carbide coarse powder as a preparation method for preparing high-strength and high-toughness boron carbide-based ceramics, and the specific steps include:

[0033] step one:

[0034] Take industrial boron carbide coarse powder, put it into a stirring ball mill tank, and use deionized water as a ball milling medium for high-speed ball milling. The specific steps of high-speed ball milling: put boron carbide coarse powder into a stirring ball mill tank, use iron balls, and the ball-to-material ratio is (8~15):1, preferably 12:1, ball milling for 48~72h, preferably 72h, rotating speed 300~600r / min, preferably 450r / min. After ball milling, hot pickling and water washing are carried out to obtain a mixed slurry of boron carbide and deionized water, and the slurry is placed in a blast drying oven for low-temperature drying to obtain boron carbide micropowder. The boron carbide fine powder has a purity of 99.9%.

[0035]...

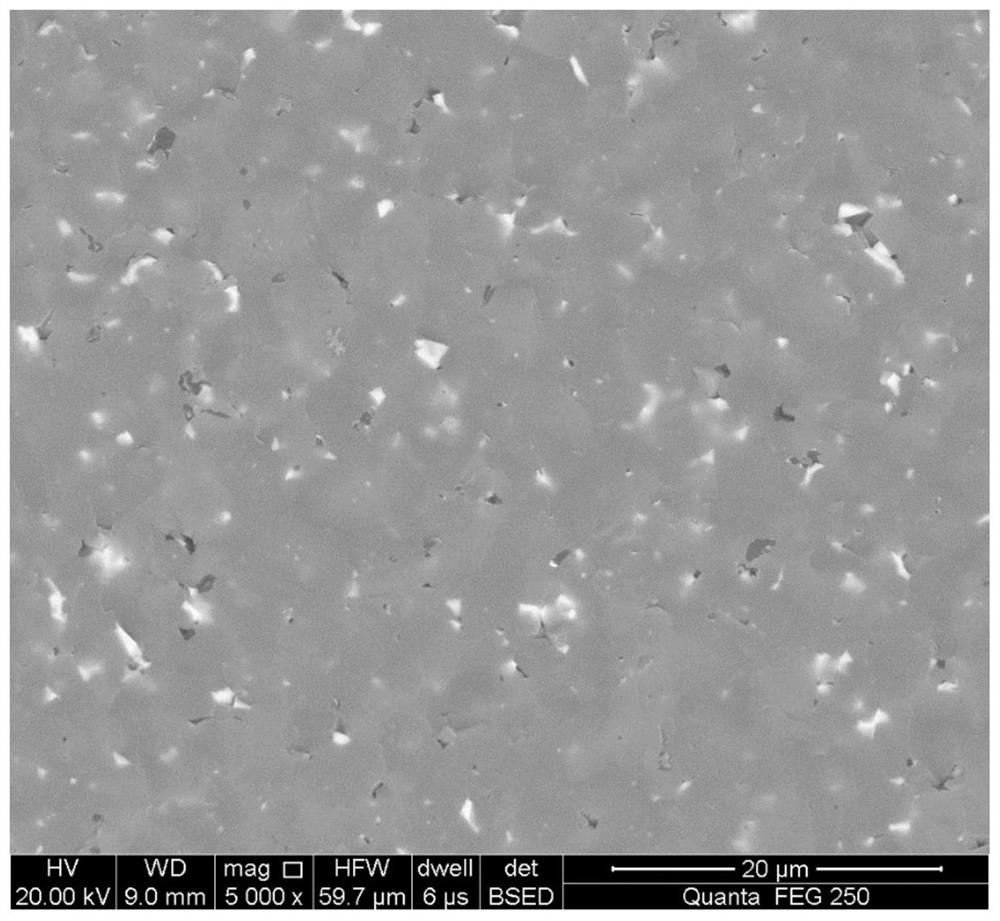

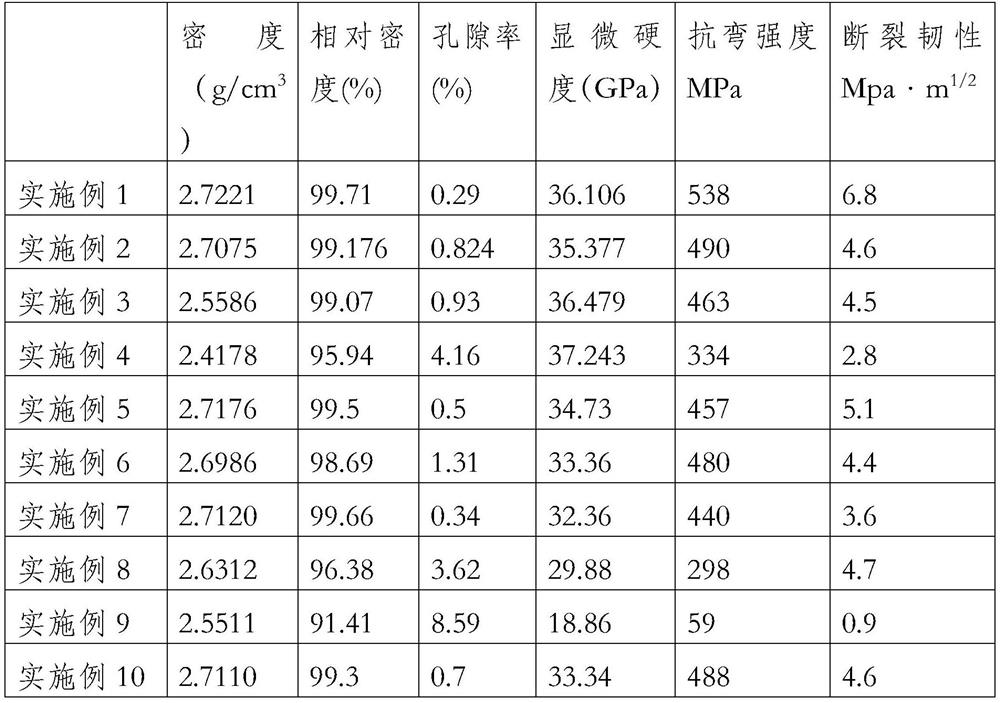

Embodiment 1

[0049] Take 200g of boron carbide coarse powder with a particle size greater than 10 μm, pickle and wash with water after high-speed ball milling for 72 hours. The specific steps of the high-speed ball milling are: put the boron carbide coarse powder into a stirring ball mill tank, use iron balls, and the ball-to-material ratio is 12: 1. Ball milling for 72 hours at a speed of 450r / min. Putting it in a blast drying oven for low-temperature drying to obtain boron carbide micropowder with an average particle diameter of 5 μm and a purity greater than 99%. Dual-phase alloy MnCoCrFe pre-alloyed powder prepared by gas atomization method: the molar ratio is Mn: Co: Cr: Fe = 3: 1: 1: 5. After smelting, use nitrogen gas atomization to make powder, and sieve 150 mesh to obtain dual phase Alloy metal powder. Weigh 95.95vol.% of boron carbide fine powder, 4vol.% of dual-phase alloy metal powder and 0.05vol.% of rare earth metal yttrium powder. The average particle size of the yttrium po...

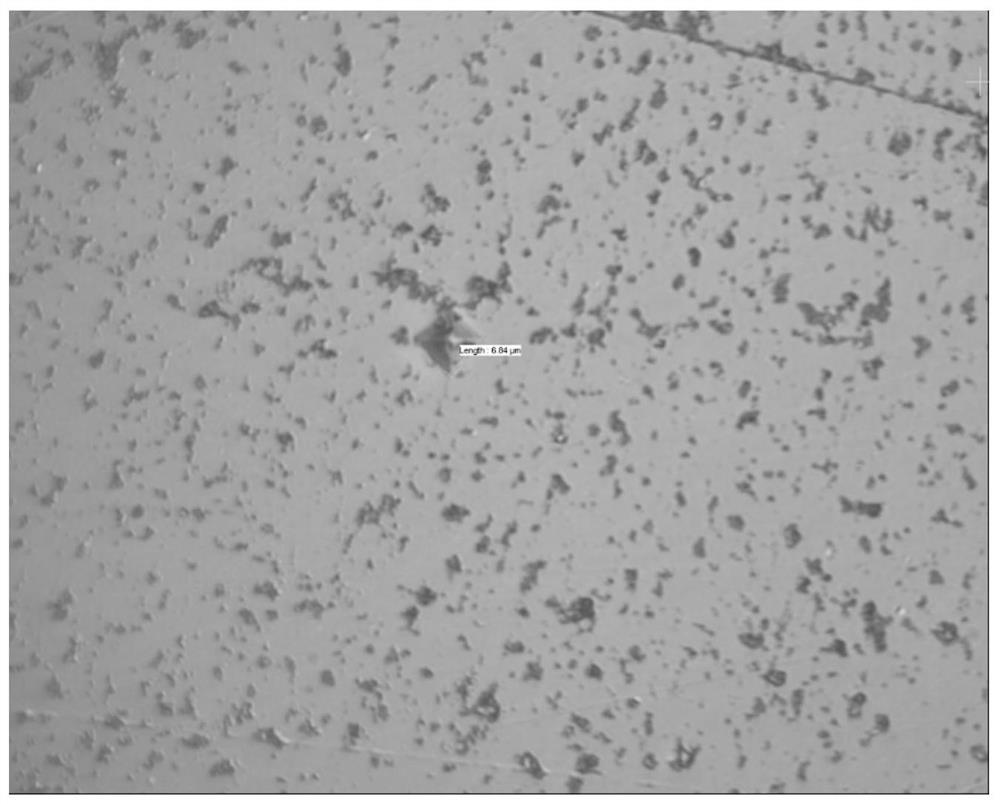

Embodiment 2

[0053] Take 200g of boron carbide coarse powder with a particle size greater than 10μm, high-speed ball milling for 72 hours, hot pickling, water washing, high-speed ball milling specific steps: put boron carbide coarse powder into a stirring ball mill tank, use iron balls, the ball-to-material ratio is 12:1 , ball milled for 72 hours, rotating speed 450r / min, placed in a blast drying oven for low-temperature drying, to obtain boron carbide powder with an average particle size of 5 μm and a purity greater than 99%. Two-phase alloy MnCoCrFe pre-alloyed powder prepared by gas atomization method: the molar ratio of metals with a fixed molar mass ratio is Mn: Co: Cr: Fe = 3: 1: 1: 5, and nitrogen gas atomization is used to make powder after smelting. Sieve through 150 mesh. Weigh 95.95vol.% boron carbide fine powder, 4vol.% dual-phase alloy powder and 0.05vol.% rare earth metal yttrium powder, mix ball mill for 3 hours, dry and grind to obtain mixed powder, the mass ratio of ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com