Method for preparing CNC (cellulose nanocrystal) by inorganic molten salt-trace acid co-promoted system

A nanocrystal and cellulose technology, applied in the field of cellulose, can solve the problems of high production and environmental protection costs, equipment corrosion, etc., and achieve the effects of simple operation, low equipment corrosion, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

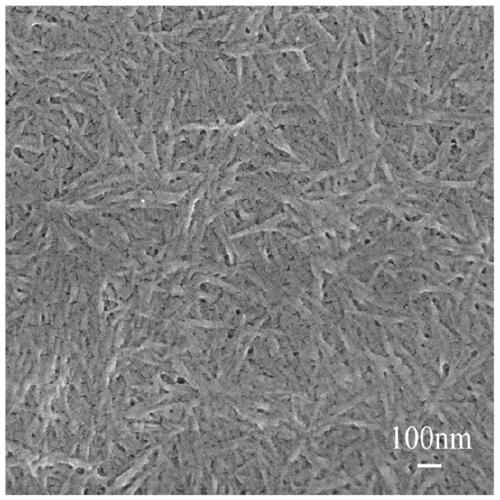

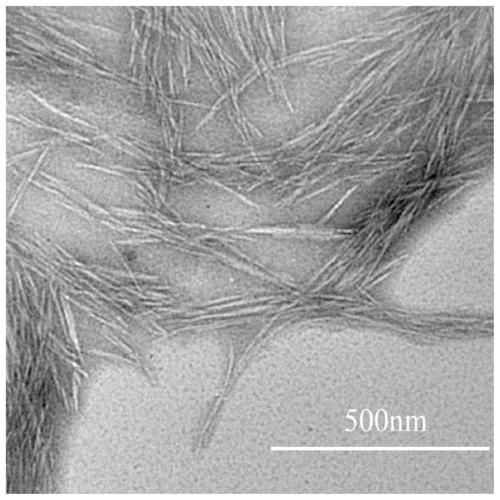

[0022] Accurately prepare 100 g of LiBr-HCl co-promoter system containing 35% LiBr and 0.1M hydrochloric acid content. Accurately weigh 5g of microcrystalline cellulose with a solid-to-liquid ratio of 1:20, add it to the LiBr-HCl co-promoting system, raise the temperature to 70°C, and keep stirring for 12 hours to obtain a homogeneous system, then perform desalting and dialysis to obtain cellulose nano The aqueous crystal solution is freeze-dried to obtain cellulose nanocrystals. The yield of cellulose nanocrystals prepared by this method is 57%, and the crystallinity is 87%. by scanning electron microscope figure 1 It can be seen from observation that the cellulose nanocrystals prepared by this method are in the shape of short rods. by transmission electron microscopy figure 2 It can be seen from observation that the average length of the cellulose nanocrystals prepared by this method is 143nm, and the average diameter is 10nm.

Embodiment 2

[0024] Accurately prepare 200g of LiCl-H containing 60% LiCl and 0.01M sulfuric acid 2 SO 4 co-promotion system. Accurately weigh 1g of absorbent cotton, the solid-to-liquid ratio is 1:200, and add it to LiCl-H 2 SO 4 In the co-promoting system, the temperature was raised to 85° C., and a homogeneous system was obtained after continuous stirring for 8 hours, and then desalting and dialysis were performed to obtain an aqueous solution of cellulose nanocrystals, which was freeze-dried to obtain cellulose nanocrystals. The yield of the cellulose nano crystals prepared by this method is 64%, the crystallinity is 82%, the average length is 131nm, the average diameter is 13nm, and it is in the shape of a short rod.

Embodiment 3

[0026] Accurately prepare 100g containing 55% CaCl 2 and formic acid content of 4M CaCl 2 -Formic acid co-promoting system. Accurately weigh 1g of pulp, the solid-to-liquid ratio is 1:100, add to CaCl 2 -In the formic acid co-promoting system, the temperature was raised to 110° C., and a homogeneous system was obtained after continuous stirring for 7 hours, and then desalted and dialysis was performed to obtain an aqueous solution of cellulose nanocrystals, which was freeze-dried to obtain cellulose nanocrystals. The yield of the cellulose nano crystals prepared by this method is 61%, the crystallinity is 79%, the average length is 137nm, the average diameter is 15nm, and it is in the shape of a short rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com