Preparation method of fluorescent carbon dots

A technology of carbon quantum dots and fluorescence, which is applied in the field of nanomaterial preparation, can solve the problems of restricting the mass production of carbon quantum dots, unfavorable practical application, and high cost of raw materials, and achieve low cost, easy acquisition, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

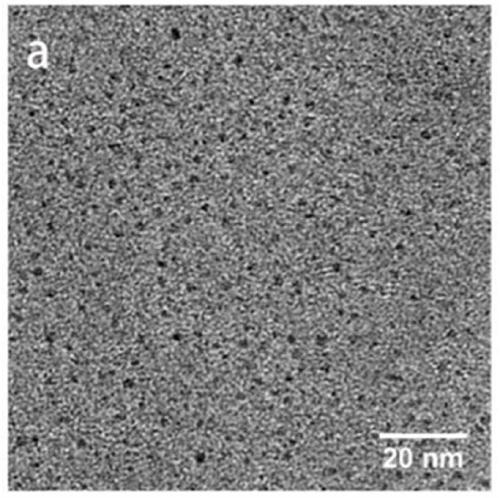

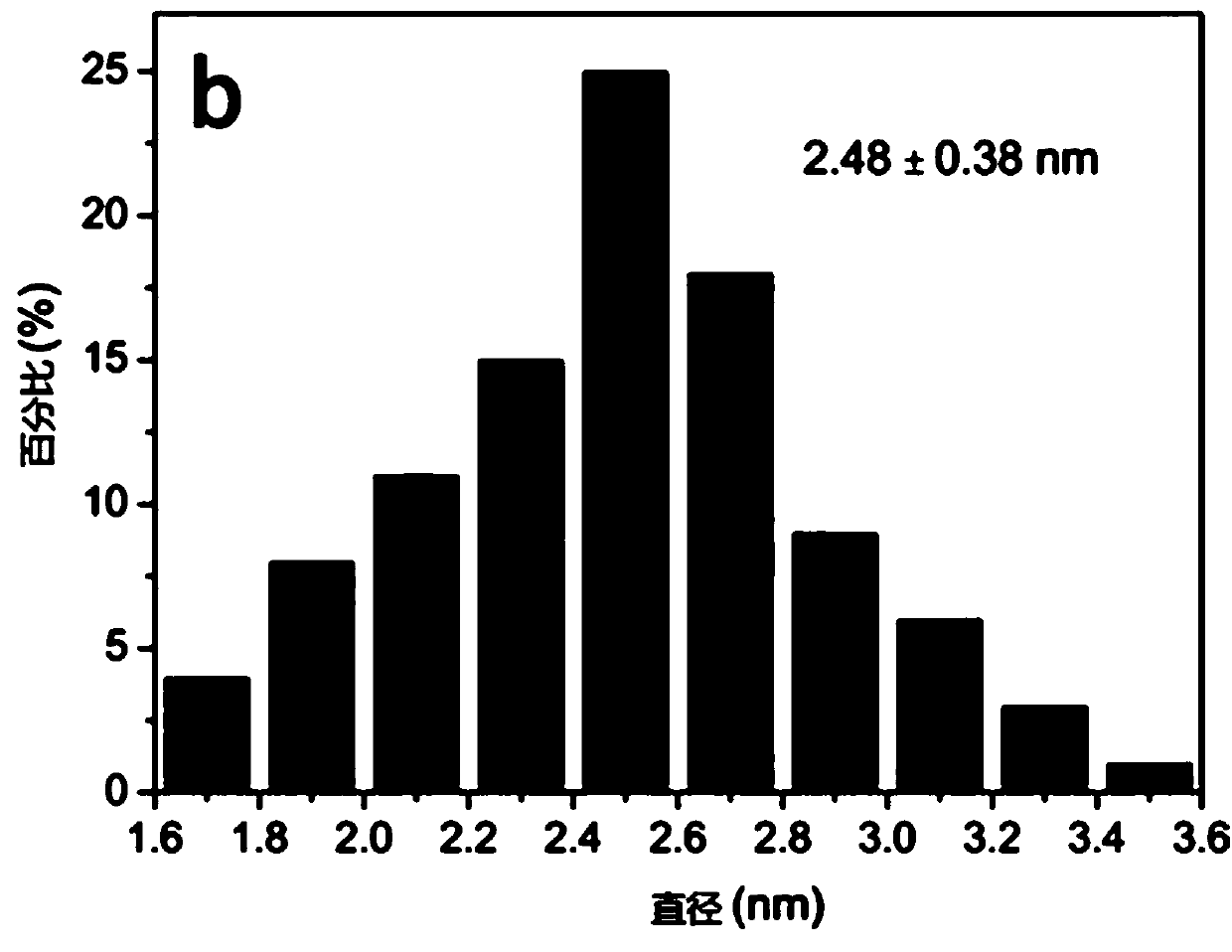

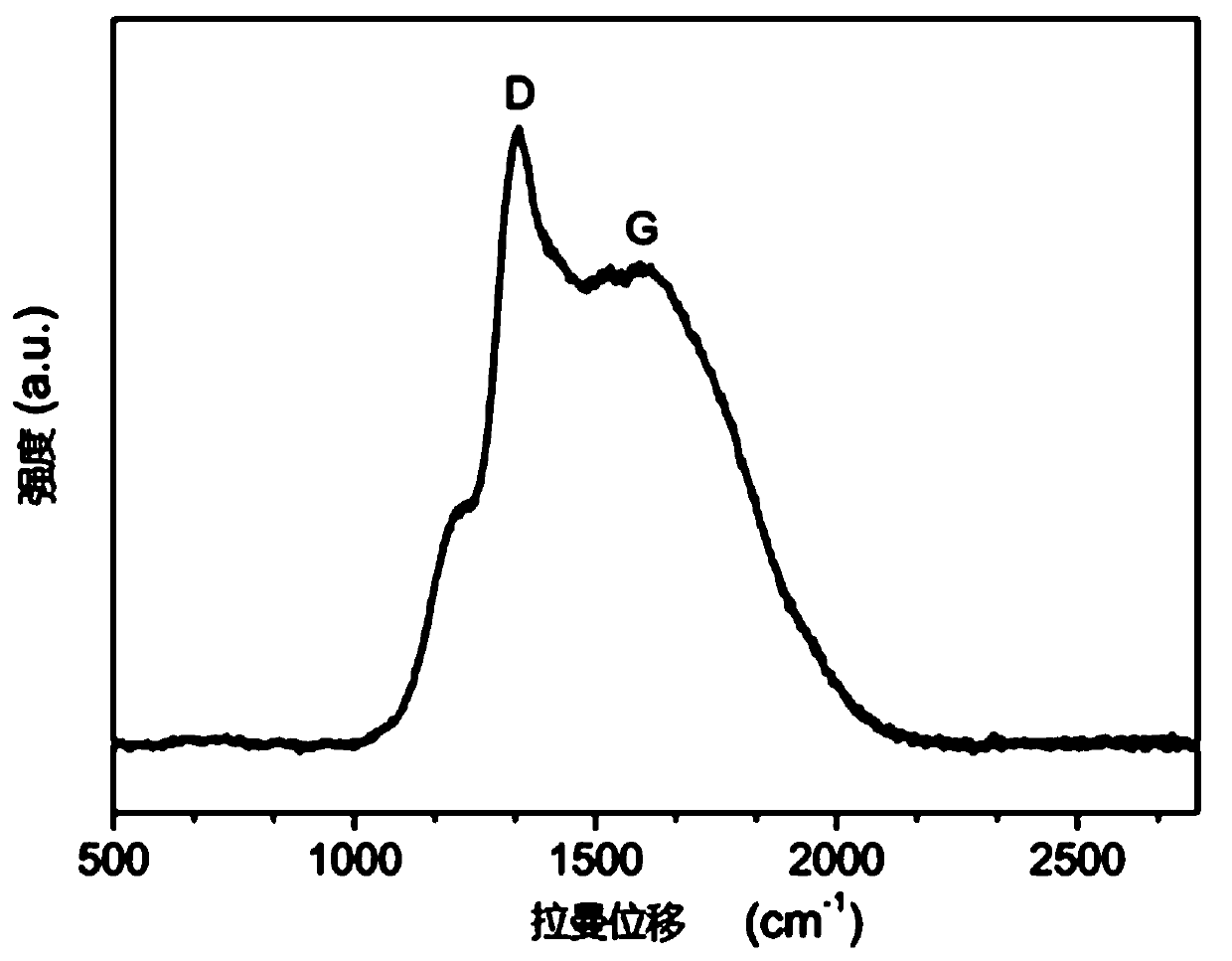

[0024] Use cyanobacteria powder as raw material, dry it at 80°C for 40 hours until the water content of cyanobacteria powder drops below 20%, and obtain dried cyanobacteria powder, and then screen the dried cyanobacteria powder with a stainless steel sieve with a pore size of 60mm. Obtain the cyanobacteria powder after screening, the weight of the cyanobacteria powder after screening is 0.2g, the cyanobacteria powder after screening mixes with 25mL pure water, stirs, obtains the mixture, transfers the mixture to the autoclave that polytetrafluoroethylene is housed, and pressurizes The capacity of the kettle was set to 50mL, heated at 120°C for 12 hours, cooled to room temperature after heating, and the reactants were collected. The reactants were filtered through a microporous membrane with a pore size of 0.22µm to remove large particles, and then dialysis The bag was dialyzed to remove all reaction residues and by-products. The dialyzing time was 36 h. Finally, it was processe...

Embodiment 2

[0026] Use cyanobacteria powder as raw material, dry it at 80°C for 40 hours until the water content of cyanobacteria powder drops below 20%, and obtain dried cyanobacteria powder, and then screen the dried cyanobacteria powder with a stainless steel sieve with a pore size of 60mm. Obtain the cyanobacteria powder after screening, the weight of the cyanobacteria powder after screening is 0.5g, the cyanobacteria powder after screening mixes with 25mL pure water, stirs, obtains the mixture, transfers the mixture to the autoclave that polytetrafluoroethylene is housed, and pressurizes The capacity of the kettle was set to 50mL, heated at 120°C for 12 hours, cooled to room temperature after heating, and the reactants were collected. The reactants were filtered through a microporous membrane with a pore size of 0.22µm to remove large particles, and then dialysis The bag was dialyzed to remove all reaction residues and by-products. The dialyzing time was 36 h. Finally, it was processe...

Embodiment 3

[0028] Use cyanobacteria powder as raw material, dry it at 80°C for 40 hours until the water content of cyanobacteria powder drops below 20%, and obtain dried cyanobacteria powder, and then screen the dried cyanobacteria powder with a stainless steel sieve with a pore size of 60mm. Obtain the cyanobacteria powder after screening, the weight of the cyanobacteria powder after screening is 0.5g, the cyanobacteria powder after screening mixes with 25mL pure water, stirs, obtains the mixture, transfers the mixture to the autoclave that polytetrafluoroethylene is housed, and pressurizes The capacity of the kettle was set to 50mL, heated at 180°C for 12 hours, cooled to room temperature after heating, and the reactants were collected. The reactants were filtered through a microporous membrane with a pore size of 0.22µm to remove large particles, and then dialysis The bag was dialyzed to remove all reaction residues and by-products. The dialyzing time was 36 h. Finally, it was processe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com