Silicon-based lithium niobate thin film electro-optic modulator array

An electro-optical modulator, silicon-based lithium niobate technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of reducing the conversion rate of electro-optical modulation, low modulation efficiency of doped silicon, and high half-wave voltage, so as to ensure functional effectiveness. and stability, improving preparation efficiency, and the effect of ultra-high modulation bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, and detailed implementation methods and structures are given, but the scope of protection of the present invention is not limited to the following examples.

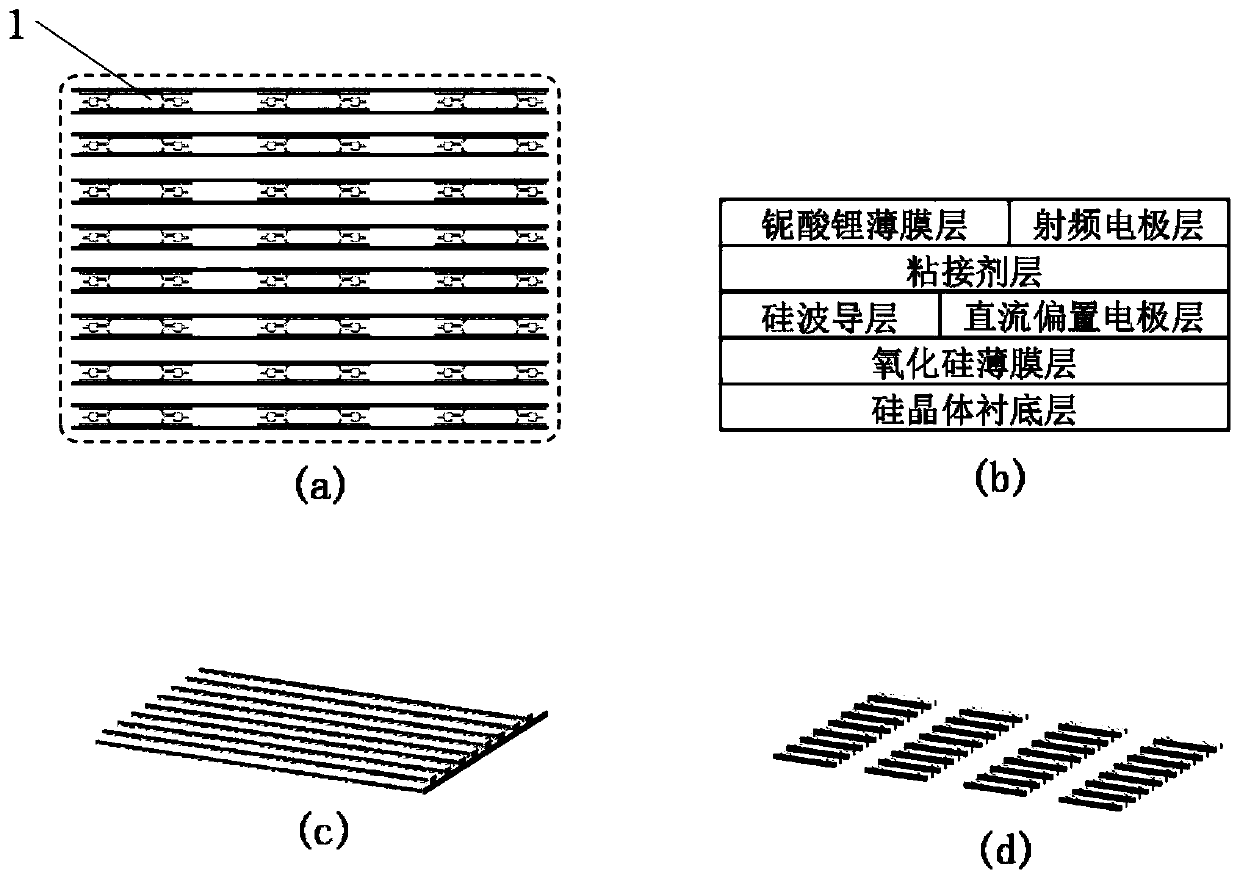

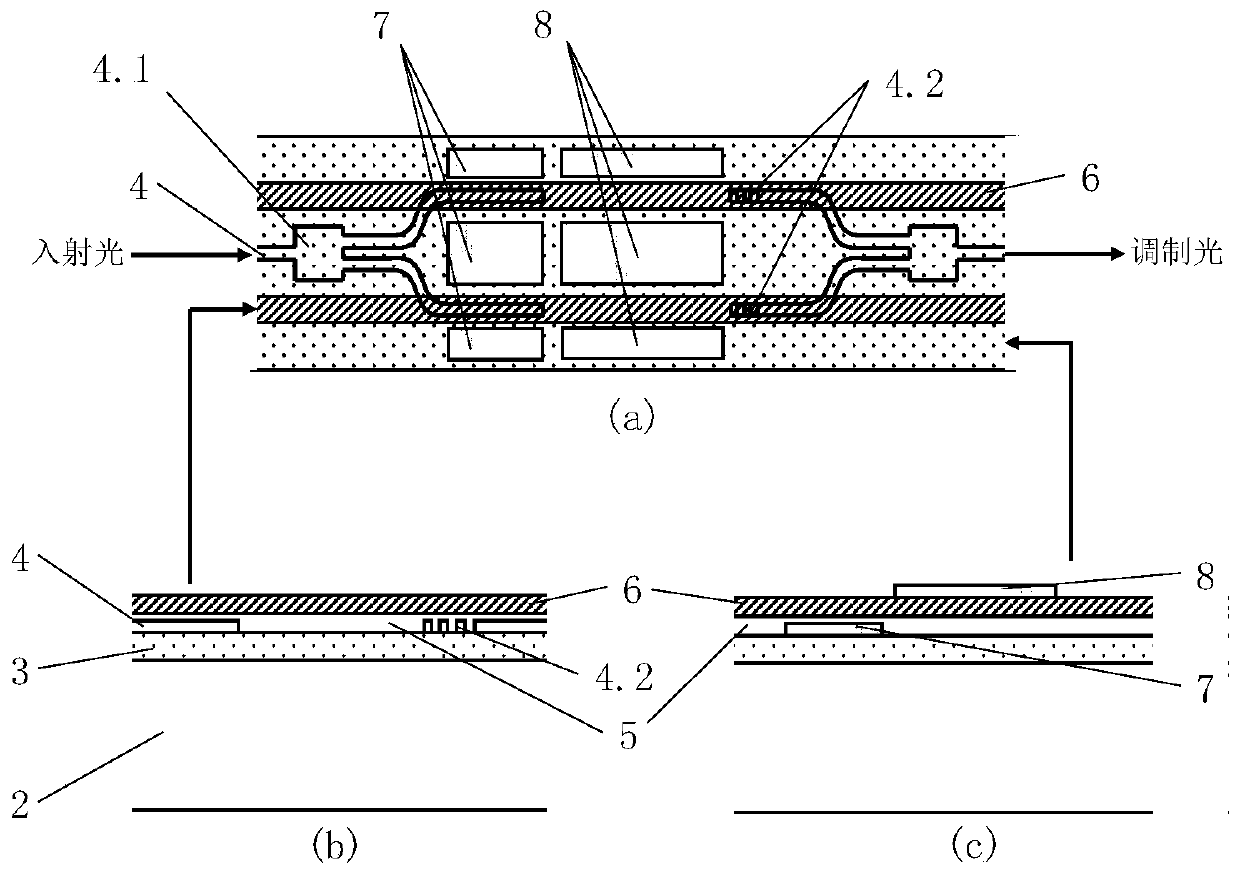

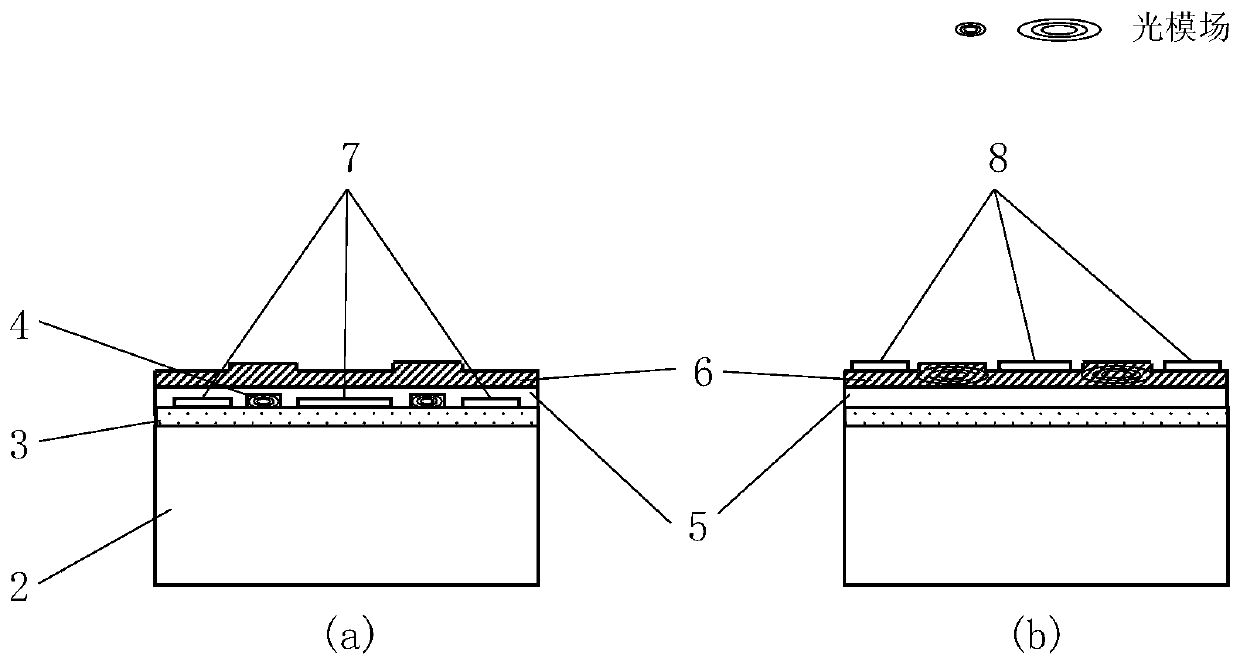

[0038] see figure 1 , the figure depicts a part of a large-scale silicon-based lithium niobate thin film electro-optic modulator array at the wafer level. It can be seen from the top view that multiple silicon-based lithium niobate thin film electro-optic modulators 1 are fabricated on one wafer at the same time. As can be seen from the schematic diagram of the longitudinal section, the silicon-based lithium niobate thin film electro-optic modulator array proposed by the present invention comprises a silicon crystal substrate layer, a silicon oxide thin film layer, a silicon waveguide layer, an adhesive layer, a lithium niobate thin film layer, a DC bias The electrode laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com