Low-temperature-resistant tackifying and toughening asphalt modifier preparation method

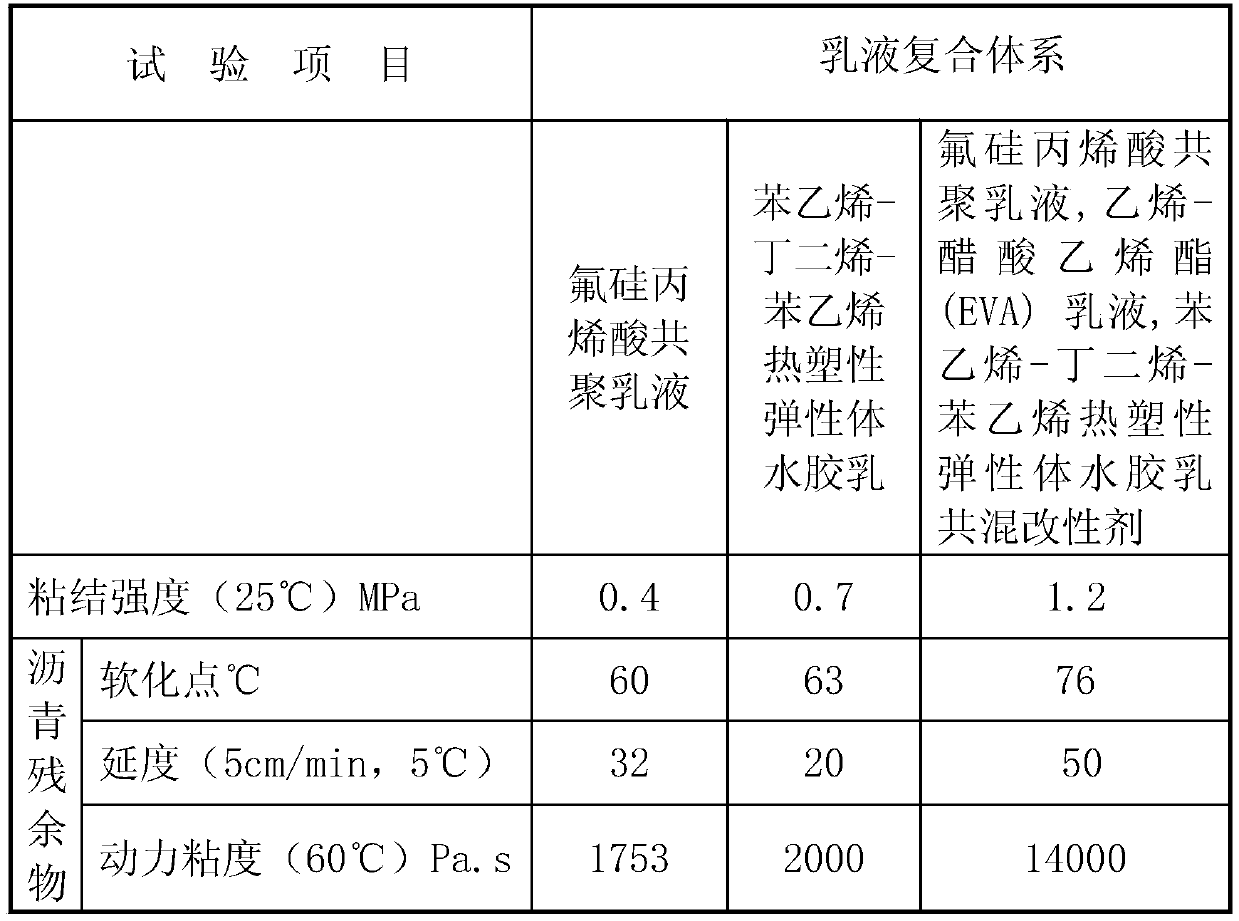

An asphalt modifier and anti-low temperature technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of reduced modification effect, difficult emulsification, and network structure damage, so as to improve low temperature performance and bond Improve performance and promote compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

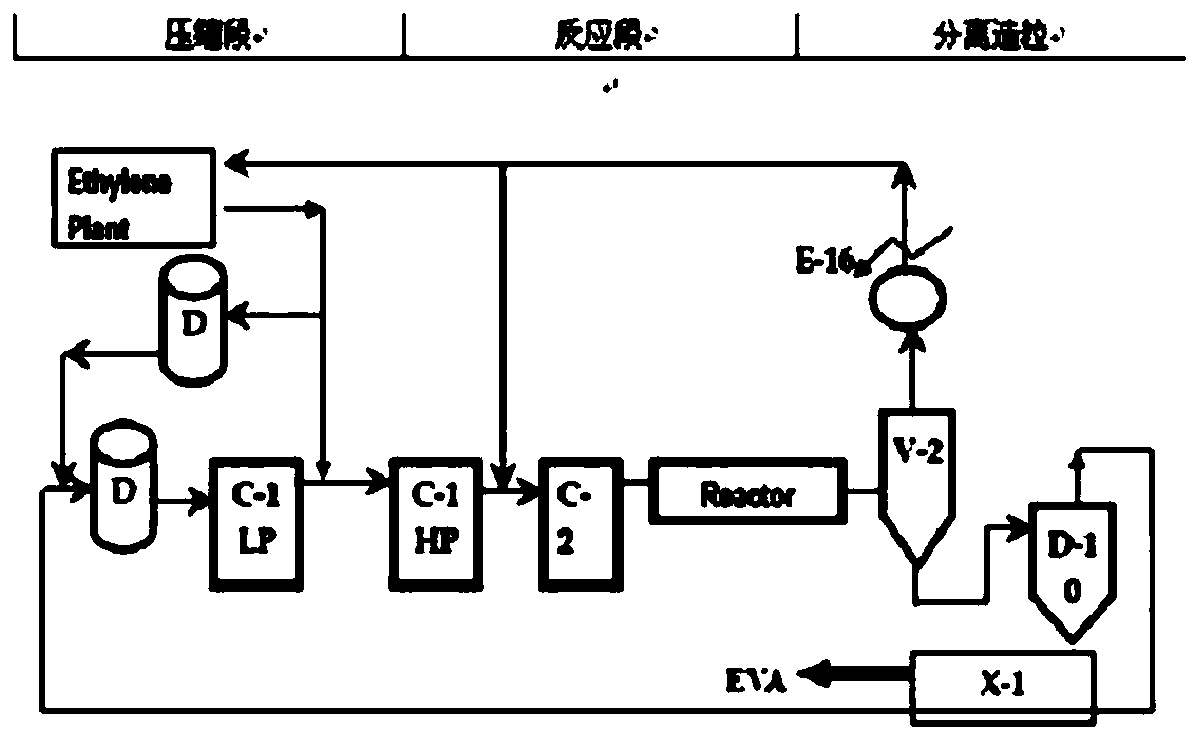

[0029] Such as figure 1 Shown, a kind of preparation method of anti-low temperature thickening and toughening asphalt modifier comprises the steps:

[0030] Step 1. Preparation of fluorosilicone-acrylic acid copolymer emulsion: using a reactor, first disperse cetyltrimethylammonium bromide and ammonium persulfate in water, then add octamethylcyclotetrasiloxane, trimethyltrifluoropropane Cyclotrisiloxane, isooctyl acrylate, butyl acrylate, fatty alcohol polyoxyethylene ether and ethylene glycol, after high-speed shearing for 15 minutes, pour one-third of the mixed solution into the reaction kettle, and the remaining mixed solution Add it dropwise evenly within three hours, and keep the temperature at 85°C until the reaction lasts for six hours to obtain a fluorosilicone acrylic acid copolymer;

[0031] Removal of residual single agglomeration: use direct steam stripping method to remove residual monomer in the degassing kettle; when the residual monomer content is 0.02%, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com