Briquette binder

A technology of binder and briquette, applied in the field of briquette binder, can solve the problems of difficulty in large-scale application of red mud, high content of heavy metals, occupation of large land, etc. The effect of improving bonding properties

Inactive Publication Date: 2020-01-21

HENAN CHANGXING IND CO LTD

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the comprehensive utilization rate of red mud in my country is only 4%, and with the continuous increase of alumina production, it not only occupies a large amount of land, but also pollutes the environment.

Due to the strong alkalinity and high content of heavy metals in red mud, it is difficult to apply red mud on a large scale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

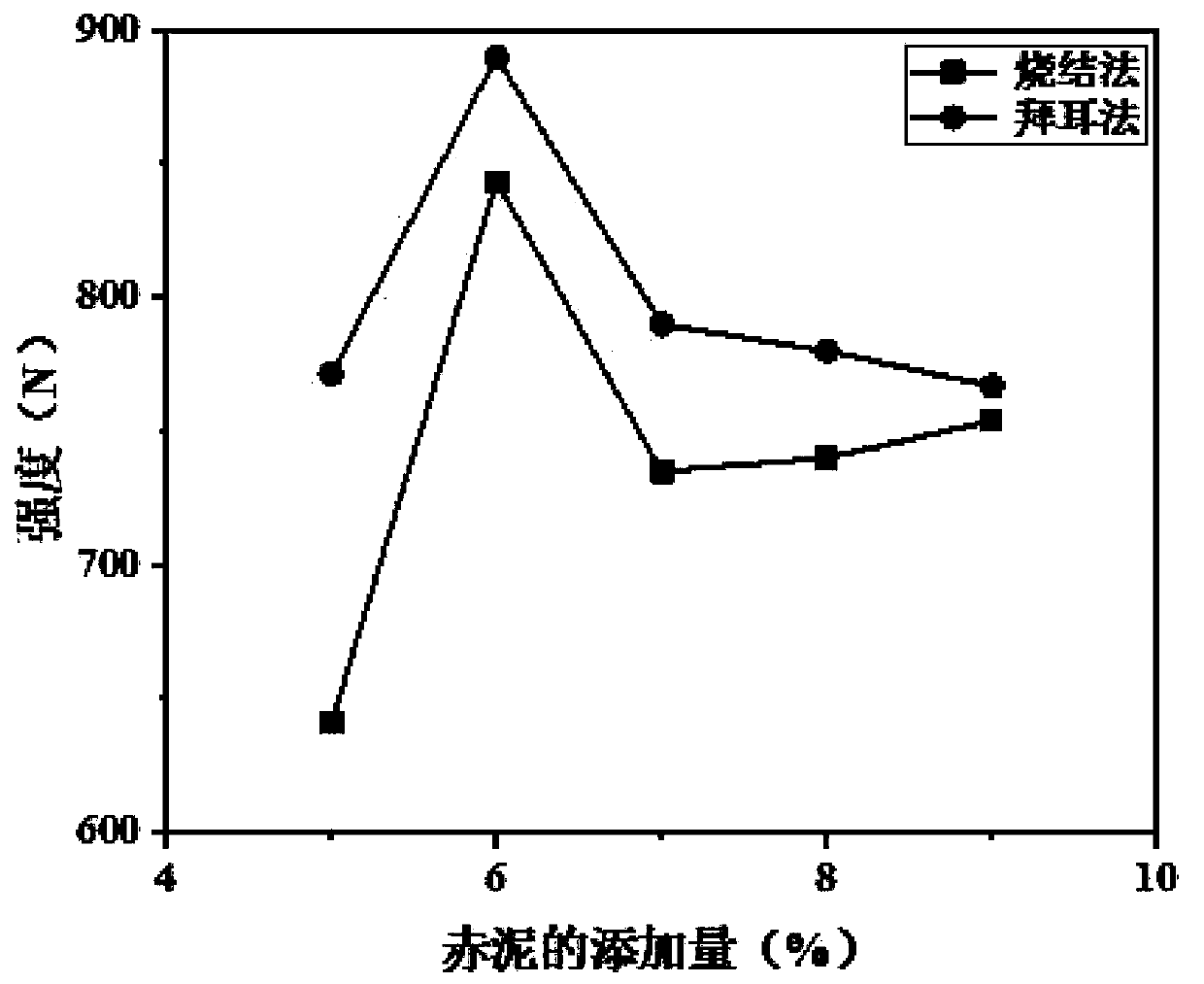

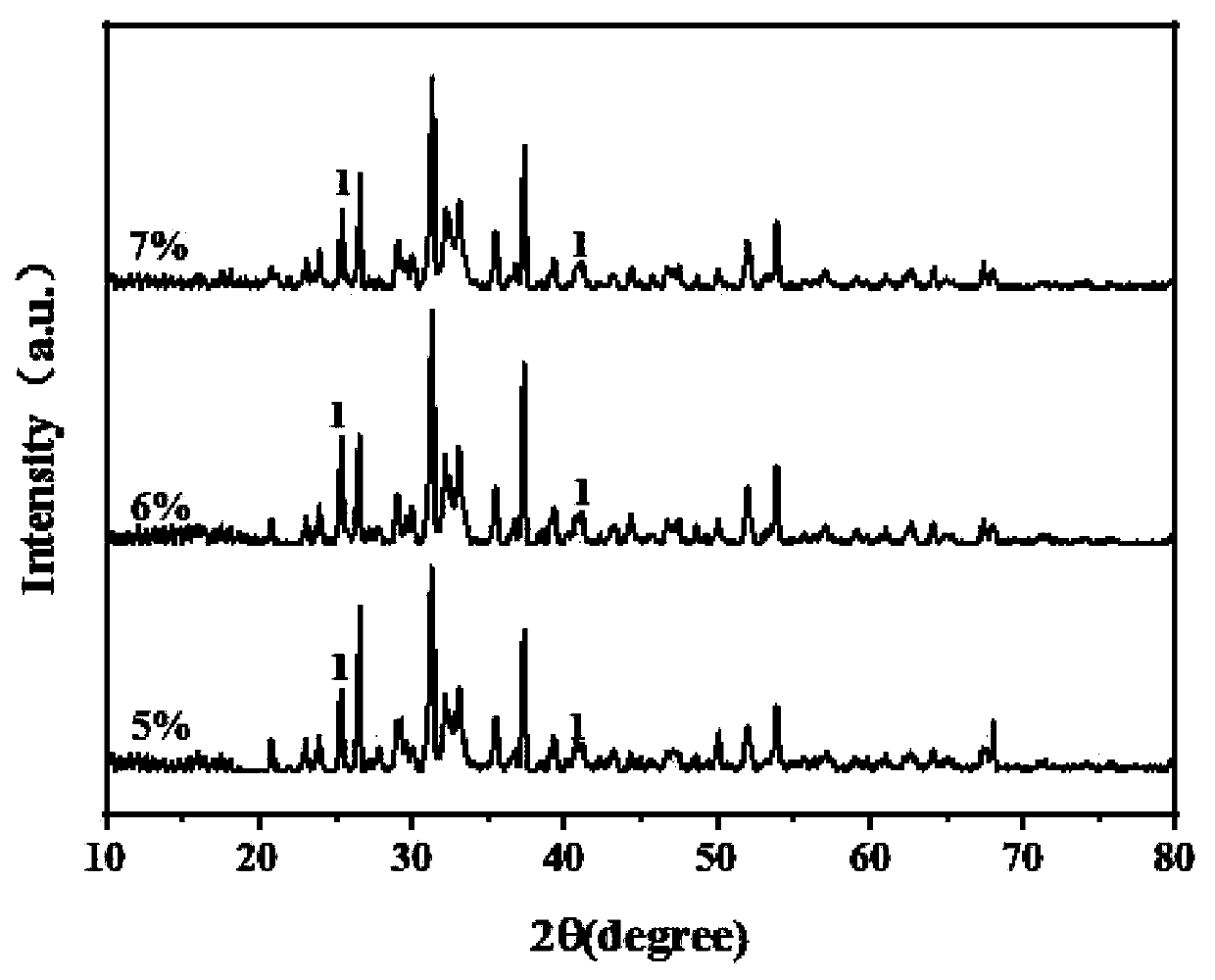

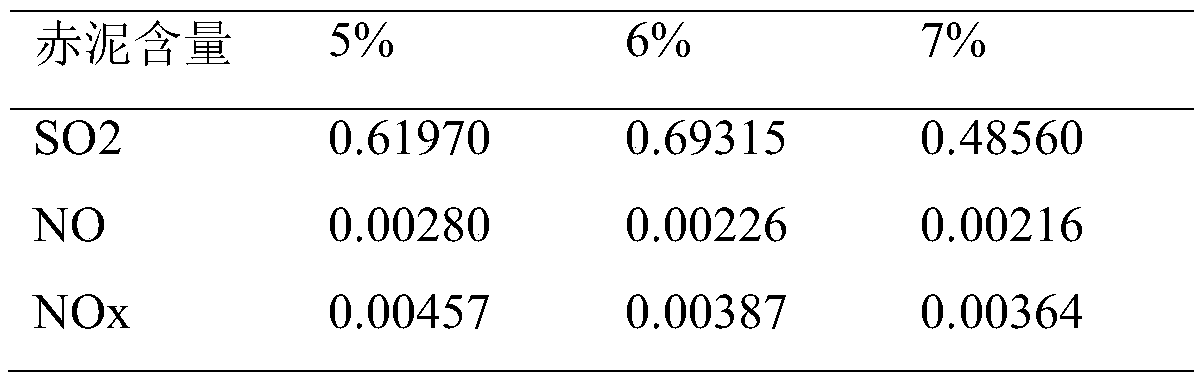

A briquette binder. Firstly, red mud is used as the binder, and alkaline substances in the red mud can be used for sulfur fixation, so that the binding performance of a starch binder can be improved,and the dosage of the binder is reduced; secondly, the binder can generate good economic benefits, is beneficial to pollution treatment of harmful gases such as SO2 in coal combustion, and achieves the effect of treating waste with waste. The briquette binder is prepared from the following raw materials in parts by weight: 5-7 parts of red mud, 1-2 parts of starch, 1 part of dispersing agent and 21 parts of water. The briquette coal is prepared by adopting the composite binder of the red mud, the starch and the dispersing agent, and the raw materials are cheap and easy to obtain. The red mud is added, so that the bonding performance of the briquette binder can be improved, and the briquette binder has a relatively good sulfur fixation effect. Red mud is used as a binder, waste is treated with waste, and the process is simple and easy to operate, and the briquette binder is proper for industrial production applications.

Description

technical field [0001] The invention relates to the technical field of coal binder preparation, in particular to a molded coal binder. Background technique [0002] my country is a country where coal is the main energy source. Coal accounts for more than 75% of the total primary energy consumption, and more than 80% is used for direct combustion. The burning of environmental protection measures will cause environmental problems such as smog and acid rain. Economic development is inseparable from the support of energy. my country's energy structure determines that coal will be the main primary energy source for a long time. Therefore, it is more feasible to use front-end control measures to achieve emission reduction. The current status of energy consumption determines that the focus of China's energy policy adjustment is on the clean and efficient use of coal. As a briquette technology of clean coal production technology, clean briquette production has the advantages of si...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L5/10

CPCC10L5/105

Inventor 蒋晓辉王倩高鹏何小山高岩

Owner HENAN CHANGXING IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com