Preparation method and application of activated sludge-graphene oxide composite material

A technology of graphene oxide and activated sludge, which is applied in the field of environmental governance, can solve the problems such as the difficulty in reusing the chemical composition of activated sludge, and the lack of a good method for immobilizing activated sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention adopts the immobilization method of activated sludge and graphene oxide, uses graphene oxide as immobilized carrier material, has prepared a kind of novel activated sludge-graphene oxide composite adsorbent, and its preparation process is as follows:

[0031] Step 1: Obtain activated sludge, grind it and centrifuge it for later use;

[0032] Step 2, dissolving the sodium seaweed in deionized water to obtain a sodium seaweed solution with a final concentration of 20 g / L;

[0033] Step 3, the graphene oxide powder is added to the sodium alginate solution to obtain a fixation solution, and the solid-to-liquid ratio of the graphene oxide powder to the embedding agent solution is 0.1:1;

[0034] Step 4, join activated sludge (wet weight, water content 95%) in the fixed solution, stir to obtain mixed solution; The solid-liquid ratio of activated sludge and fixed solution is 0.06:1;

[0035] Step 5. Gradually drop the mixed solution into the calcium chlo...

Embodiment 2

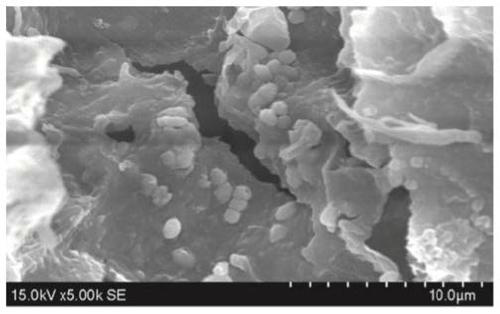

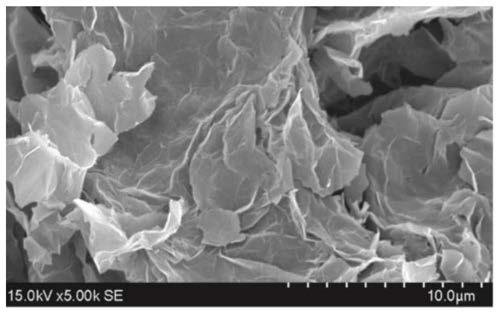

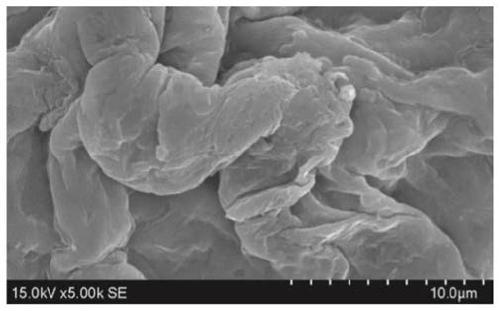

[0038] 1. The morphology of AS, GO and AS-GO samples is shown in Figure 1. As can be seen from Fig. 1, the image of AS showed that the sludge surface was a leaf cluster structure with a rough surface, and many rod-shaped and spherical bacteria were clearly observed on the surface of AS. The SEM images of GO supports show that GO has a highly wrinkled structure with a lateral size of several nanometers, randomly aggregated and closely combined to form a disordered solid. Compared with the pristine AS and GO samples, the SEM micrographs of the AS-GO samples showed obvious shape changes, and the AS samples were tightly covered and embedded in the GO samples due to the immobilization process. This indicates that GO is a well-supported carrier for AS, and AS-GO has a rough and relatively dense surface, which can improve stability and avoid the erosion of radionuclides and heavy metals.

[0039] 2. The adsorption effect of AS-GO on uranium in the pH range of 2-7 is as follows: im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com