Physical vapor deposition (PVD) flexible conducting film, preparation method, and method for generating microcircuit through nanometer effect

A flexible conductive and nano-effect technology, applied in circuits, conductive layers on insulating carriers, semiconductor/solid-state device manufacturing, etc., can solve problems such as high cost, inability to make special-shaped circuits, and scrapped finished circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method for a PVD flexible conductive film, comprising the following steps:

[0033] (1) Using the physical vapor deposition (PVD) vacuum evaporation method, in a vacuum environment, the base layer material is evaporated into vapor phase deposition on the substrate to form the base layer 1;

[0034] (2) melting and mixing the conductive material;

[0035] (3) Using the physical vapor deposition (PVD) sputtering coating method, in a vacuum environment, through the joint action of voltage and magnetic field, the conductive material is bombarded with ionized inert gas ions, so that the conductive material is ionized in the form of ions It is sputtered out and deposited on the base layer 1 to form a conductive layer 2, thereby preparing a flexible conductive film.

[0036] Further, the evaporation source used for evaporation in the step (1) is resistance heating, electron beam heating, laser heating, high frequency induction heating or arc heating.

[0037] F...

Embodiment 1

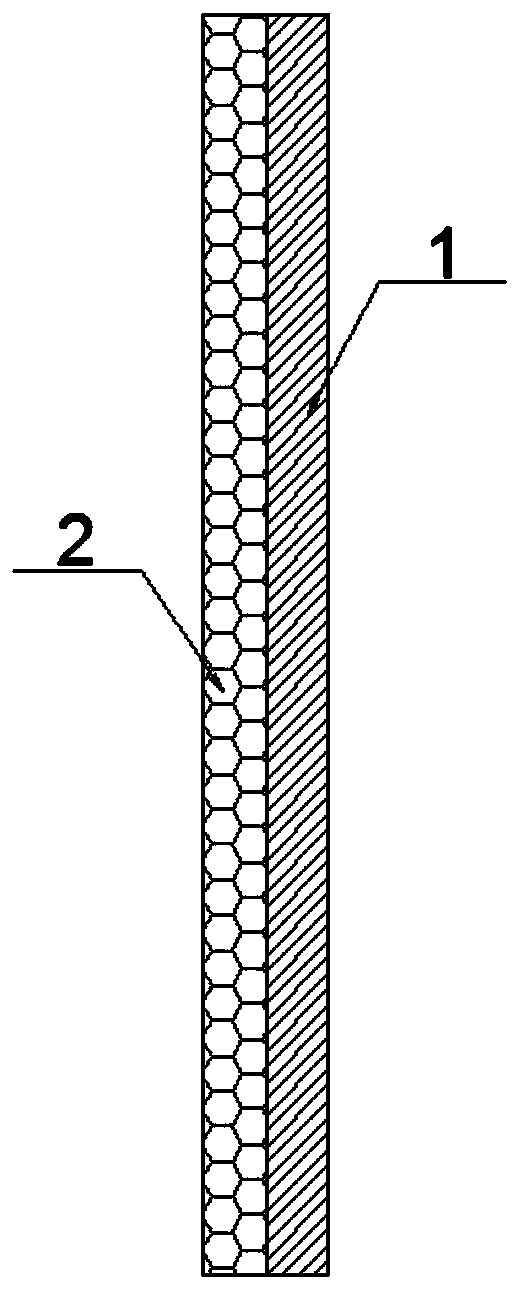

[0047] A PVD flexible conductive film includes a base layer 1 and a conductive layer 2 deposited on the base layer.

[0048] Further, the material of the base layer 1 is indium tin oxide.

[0049] Further, the material of the conductive layer 2 is a mixture of gold and tin.

[0050] A preparation method for a PVD flexible conductive film, comprising the following steps:

[0051] (1) Using the physical vapor deposition (PVD) vacuum evaporation method, in a vacuum environment, the base layer material is evaporated into vapor phase deposition on the substrate to form the base layer 1;

[0052] (2) melting and mixing the conductive material;

[0053] (3) Using the physical vapor deposition (PVD) sputtering coating method, in a vacuum environment, through the joint action of voltage and magnetic field, the conductive material is bombarded with ionized inert gas ions, so that the conductive material is ionized in the form of ions It is sputtered out and deposited on the base laye...

Embodiment 2

[0065] A PVD flexible conductive film includes a base layer 1 and a conductive layer 2 deposited on the base layer.

[0066] Further, the material of the base layer 1 is zinc oxide.

[0067] Further, the material of the conductive layer 2 is a mixture of gold and tin.

[0068] A preparation method for a PVD flexible conductive film, comprising the following steps:

[0069] (1) Using the physical vapor deposition (PVD) vacuum evaporation method, in a vacuum environment, the base layer material is evaporated into vapor phase deposition on the substrate to form the base layer 1;

[0070] (2) melting and mixing the conductive material;

[0071] (3) Using the physical vapor deposition (PVD) sputtering coating method, in a vacuum environment, through the joint action of voltage and magnetic field, the conductive material is bombarded with ionized inert gas ions, so that the conductive material is ionized in the form of ions It is sputtered out and deposited on the base layer 1 to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap