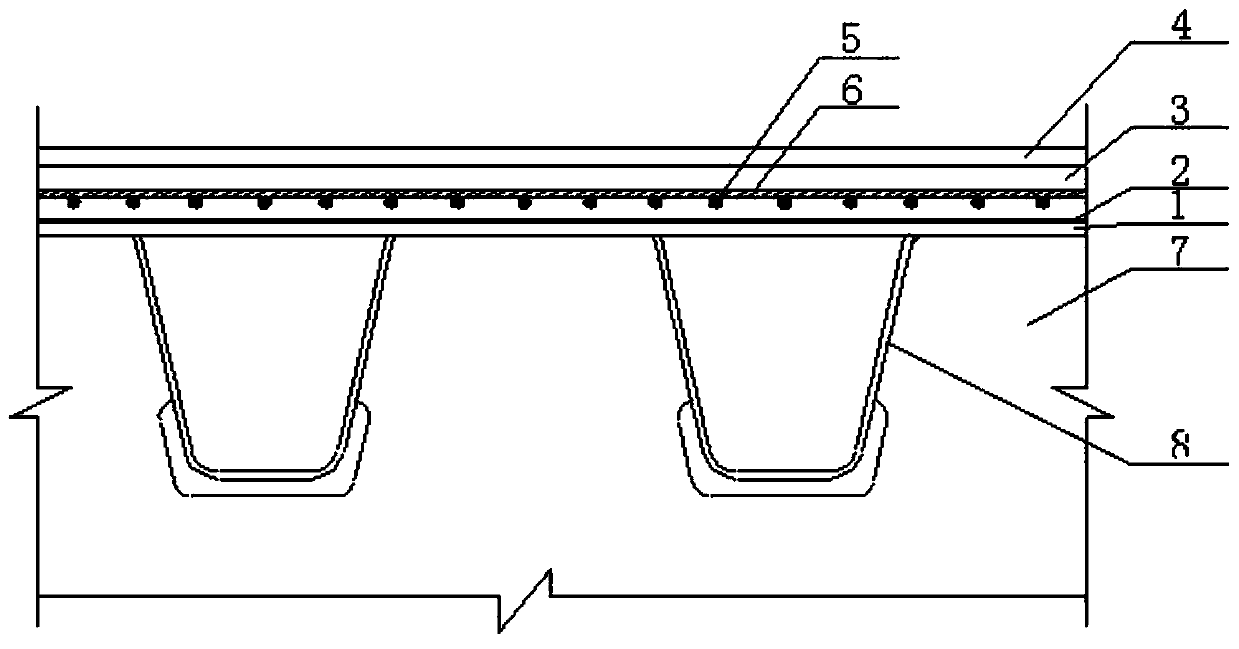

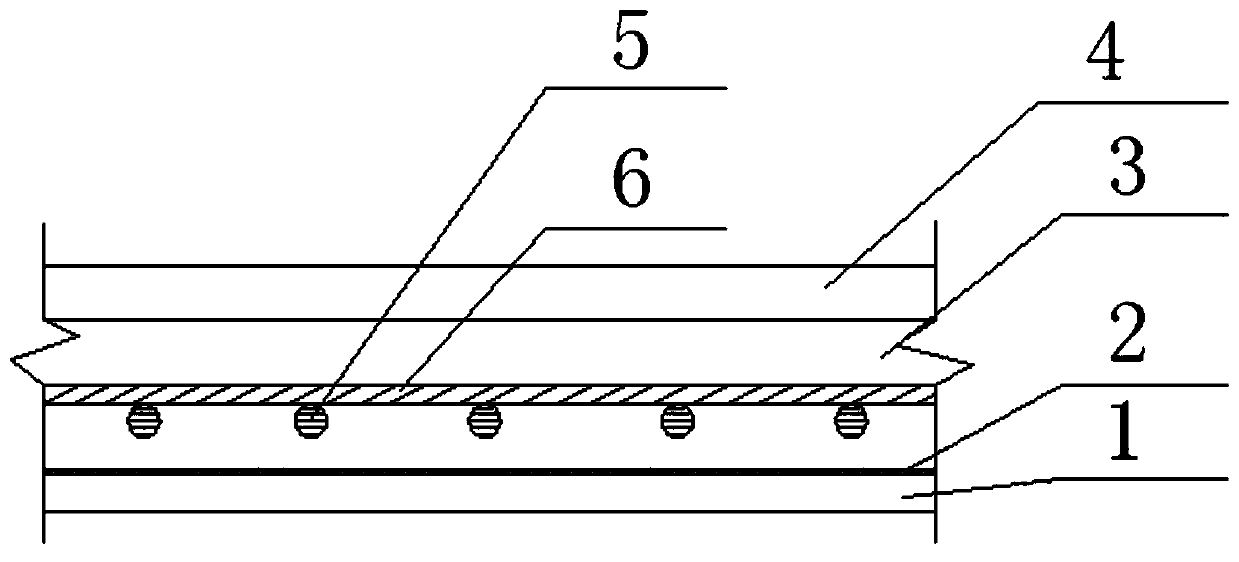

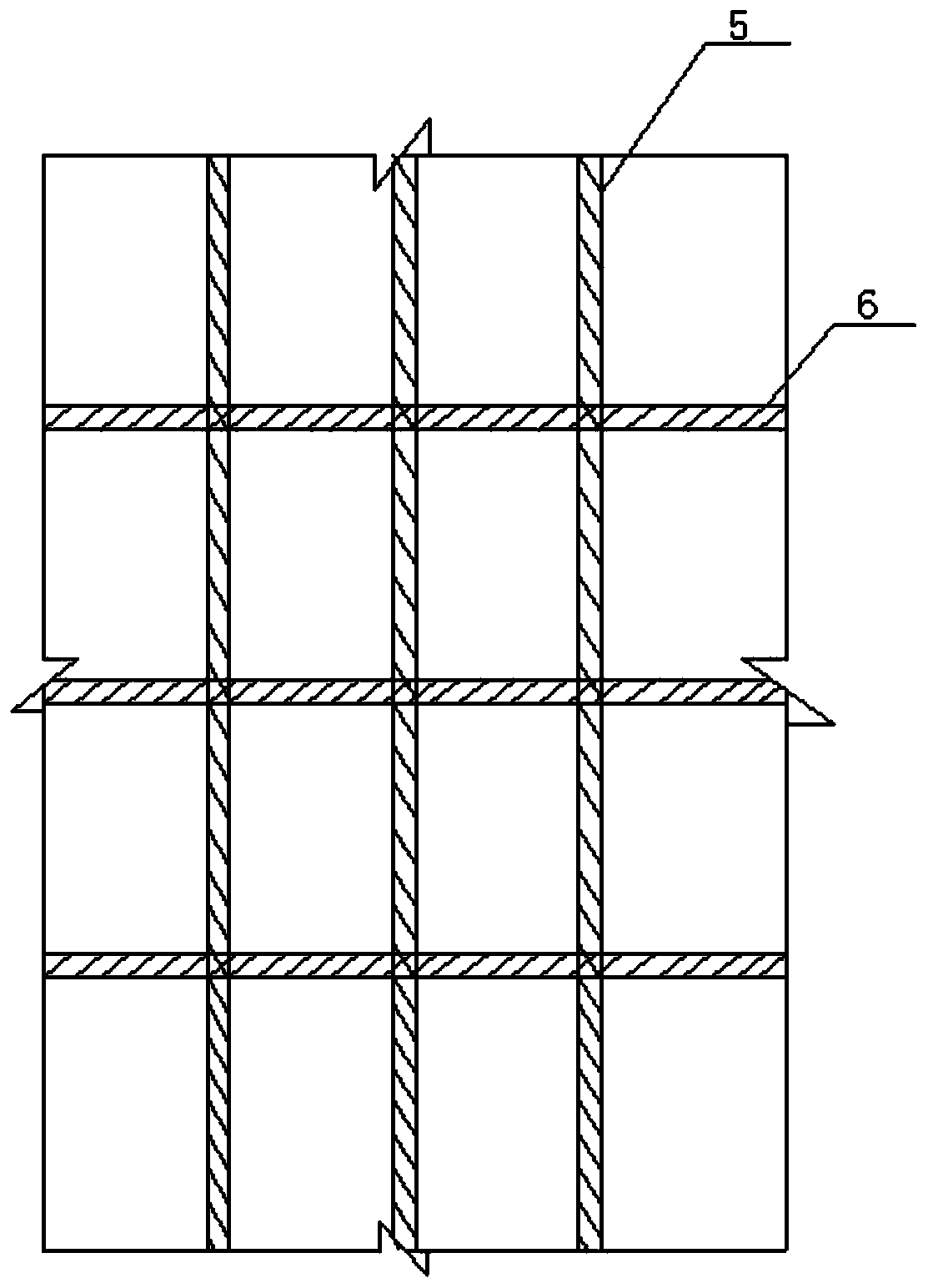

Orthotropic steel plate-ultrahigh-performance concrete composite bridge deck structure and construction method thereof

An ultra-high performance, orthotropic technology, used in polymer adhesive additives, non-polymer adhesive additives, bridges, etc., can solve the problem of UHPC self-shrinkage, which cannot be factory prefabricated, and the height of stud shear bond Large and other problems, to achieve the effect of simple overall structure, solving fatigue diseases and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of construction method of above-mentioned bridge deck structure, comprises the steps:

[0033] S1. Erection of steel girders: Carry out the prefabrication and on-site splicing of steel girders in sequence according to conventional steel bridge construction methods until the steel girder erection is completed to obtain the steel bridge deck;

[0034]S2. Preparation of adhesive, laying adhesive layer on the steel bridge deck: the adhesive includes the following components in parts by weight: 95 parts of matrix resin, 29 parts of curing agent, 18 parts of toughening agent, 2.5 parts of coupling agent, 4 parts of thixotropic agent, 0.5 part of thixotropic agent and 0.04 part of nanofiller; the matrix resin includes 59 parts of bisphenol A type epoxy resin and 36 parts of heat-resistant resin in parts by weight, and the heat-resistant resin includes Hydantoin epoxy resin, phenolic resin, polyfunctional heat-resistant epoxy resin, cycloaliphatic glycidyl ester trifunct...

Embodiment 2

[0038] A kind of construction method of above-mentioned bridge deck structure, comprises the steps:

[0039] S1. Erection of steel girders: Carry out the prefabrication and on-site splicing of steel girders in sequence according to conventional steel bridge construction methods until the steel girder erection is completed to obtain the steel bridge deck;

[0040] S2. Prepare an adhesive and lay an adhesive layer on the steel bridge deck: the adhesive includes components A and B by weight. Among them, component A includes 100 parts of matrix resin, 30 parts of toughening agent, 3 parts of coupling agent, 1 part of thixotropic agent and 0.06 parts of nano filler; component B includes 35 parts of curing agent, 6 parts of accelerator, ; The matrix resin includes 70 parts by weight of bisphenol A type epoxy resin and 30 parts of heat-resistant resin, and the heat-resistant resin includes hydantoin epoxy resin, phenolic resin, polyfunctionality heat-resistant ring One or more of ox...

Embodiment 3

[0044] A kind of construction method of above-mentioned bridge deck structure, comprises the steps:

[0045] S1. Erection of steel girders: Carry out the prefabrication and on-site splicing of steel girders in sequence according to conventional steel bridge construction methods until the steel girder erection is completed to obtain the steel bridge deck;

[0046] S2. Prepare an adhesive and lay an adhesive layer on the steel bridge deck: the adhesive includes components A and B by weight. Among them, component A includes 105 parts of matrix resin, 42 parts of toughening agent, 3.5 parts of coupling agent, 1.5 parts of thixotropic agent and 0.08 parts of nanofiller; component B includes 38 parts of curing agent and 8 parts of accelerator; The matrix resin includes 74 parts by weight of bisphenol A type epoxy resin and 31 parts of heat-resistant resin, and the heat-resistant resin includes hydantoin epoxy resin, phenolic resin, multifunctional heat-resistant epoxy resin One or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com