Supported metal M vanadate SCR catalyst and preparation method thereof

An SCR catalyst and a supported technology are applied in the field of supported vanadate SCR catalysts and their preparation to achieve the effects of simple and feasible preparation process, easy control of preparation conditions and less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

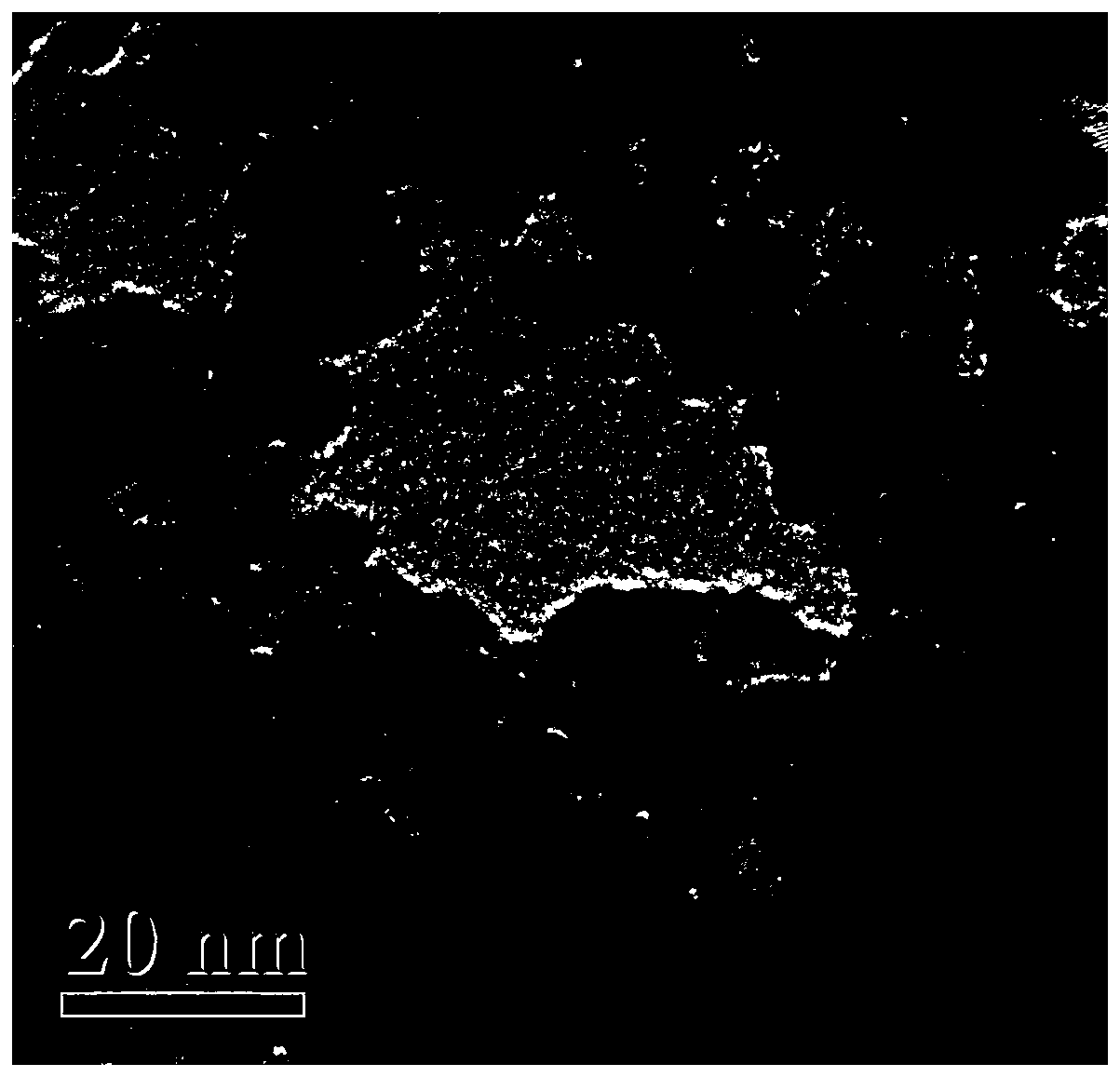

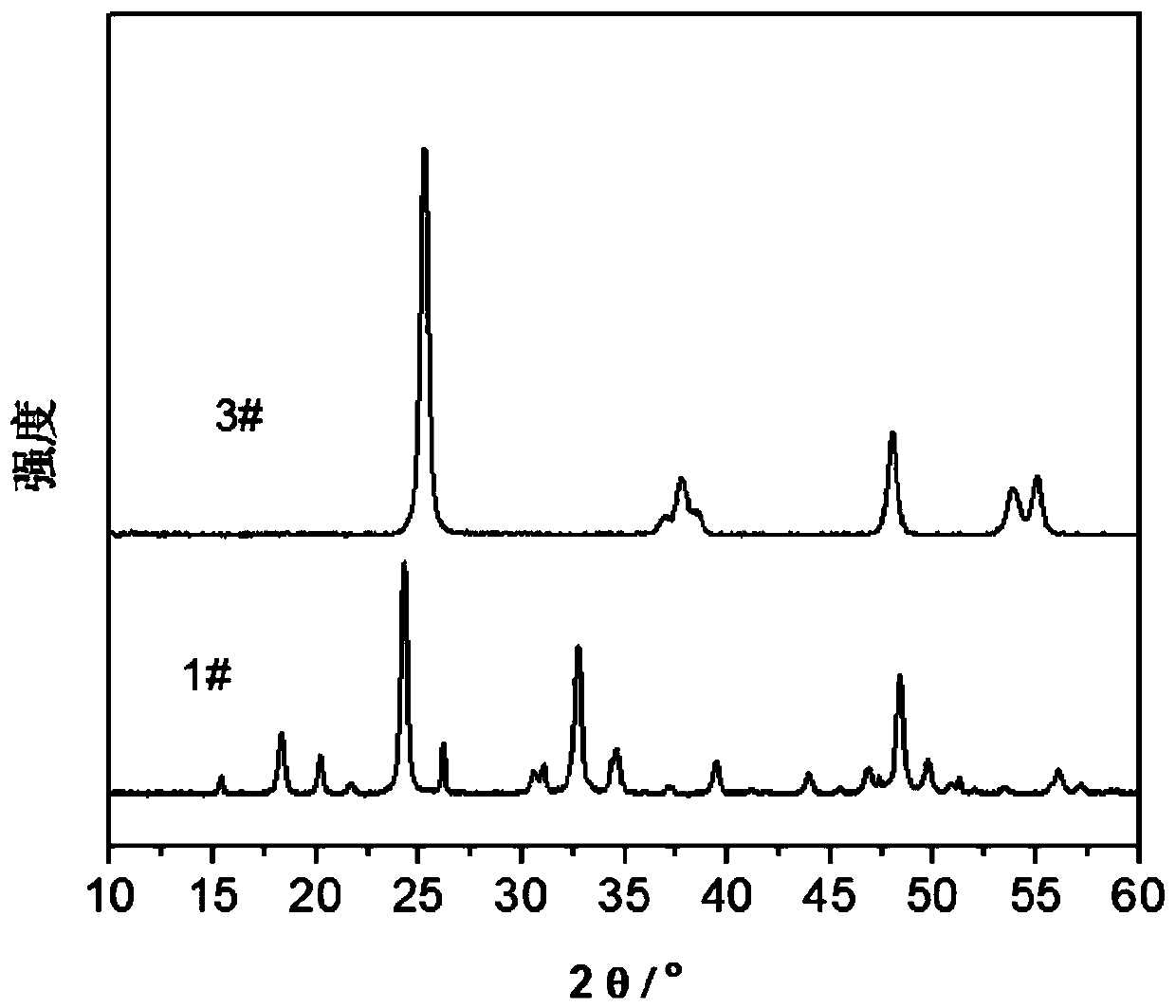

[0028] Accurately weigh 1.17g of ammonium metavanadate and 4.02g of niobium nitrate and dissolve them in 50ml of deionized water respectively. After they are completely dissolved, add 1.0g of PEG-4000 to the ammonium metavanadate solution and stir to dissolve. Add the niobium nitrate solution dropwise to the ammonium metavanadate solution. After the dropwise addition, stir for 30 minutes, then boil it in a microwave oven, take it out, let it stand, remove the supernatant, dry and roast to obtain the 1# sample.

Embodiment 2

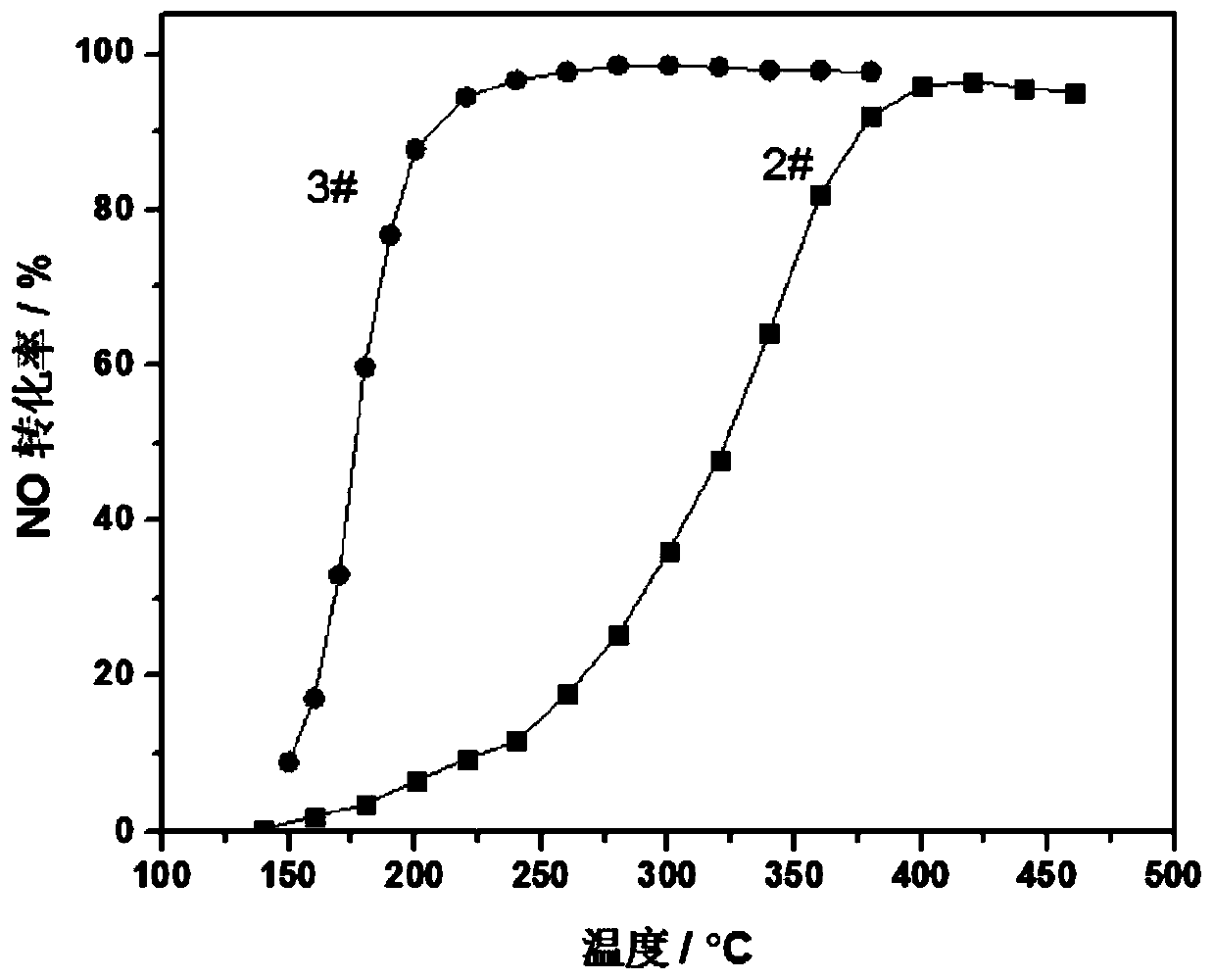

[0030] Accurately weigh 0.144g of ammonium metavanadate, dissolve it in 50ml of deionized water, then add 0.4g of PEG-4000, stir until completely dissolved, then add 10g of TiO 2 Powder; in addition, weigh 0.495g of niobium nitrate and dissolve it in 30ml of water, add it dropwise to the above solution, stir for 30 minutes, then boil it in a microwave oven, evaporate the solvent, dry it at 100°C, and transfer it to a muffle furnace Calcined at 500°C for 3h to obtain 2# sample.

Embodiment 3

[0032]Accurately weigh 0.485g of ammonium metavanadate, dissolve it in 50ml of deionized water, then add 1.0g of PEG-4000, stir until completely dissolved, then add 10g of TiO 2 Powder; in addition, weigh 1.654g of niobium nitrate and dissolve it in 30ml of water, add it dropwise to the above solution, stir for 30min, boil it in a microwave oven, evaporate the solvent, dry it at 100°C, and transfer it to a muffle furnace Calcined at 500°C for 3h to obtain 2# sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com