Method for repairing damaged dental enamel by metal oxide compact layer coating

A technology of oxide and tooth enamel, which is applied in the field of controllable preparation of metal oxide repair layer, to achieve the effect of simple operation, recovery of mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation method of zirconia restoration layer with tight connection with tooth enamel

[0036] In the first step, add 100 mL of distilled water to the beaker, stir in a water bath at 25°C for 10 minutes until the temperature is stable, add Tris / concentrated HCl buffer reagent, in which Tris is 0.848 g, concentrated HCl is 465 microliters, and the reaction pH is maintained at about 7.5 ;

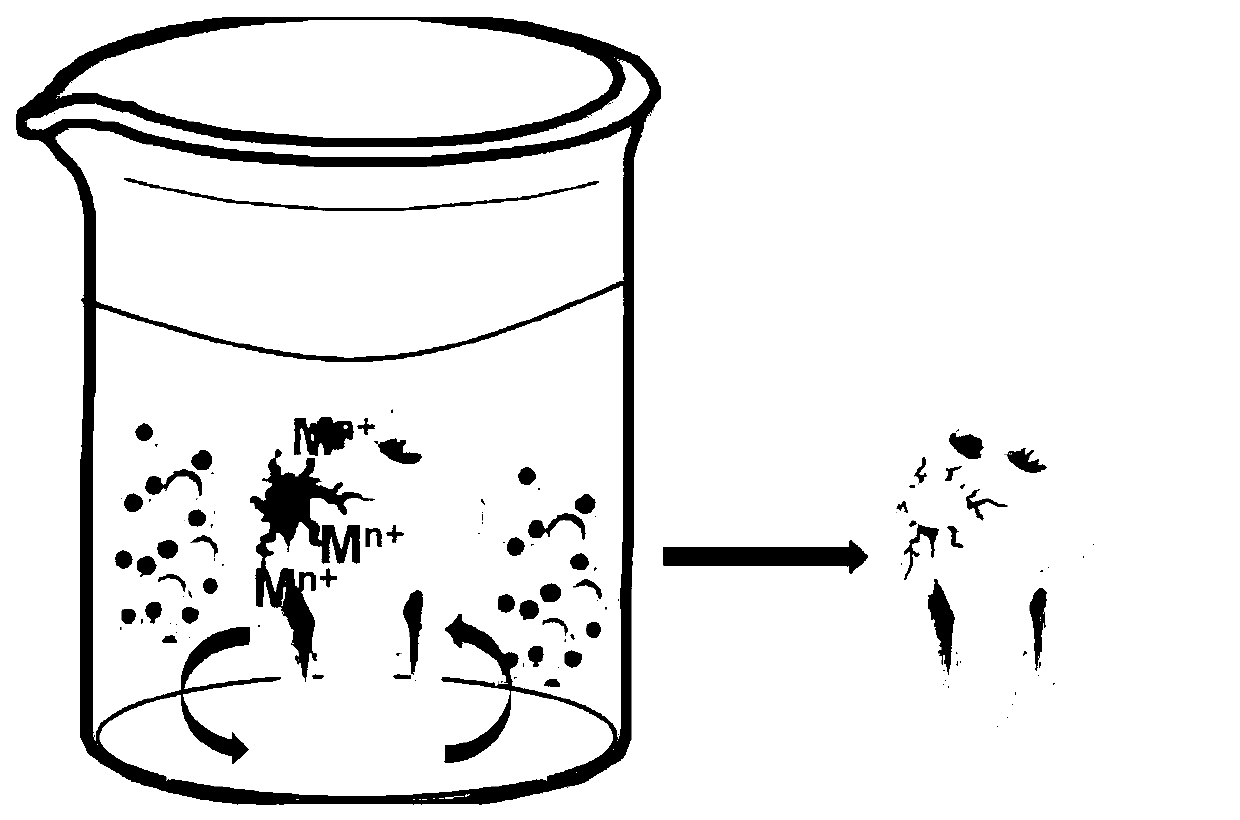

[0037] In the second step, add 14 mg of ZrOCl to the solution prepared in the first step 2 2H 2 O powder, stir at 10-25°C for 10 minutes until completely dissolved ( figure 1 );

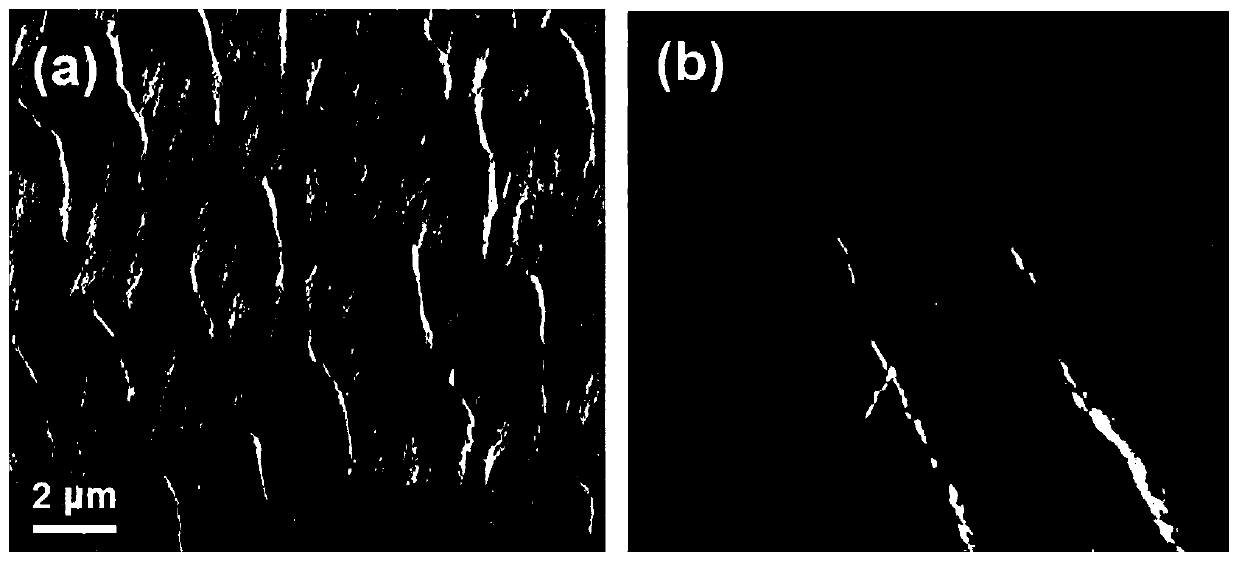

[0038] The third step is to slice the damaged enamel to be repaired ( figure 2 ) placed in the solution prepared in the second step ( figure 1 ), and continued to stir for 3h to obtain enamel coated with zirconia precursor;

[0039] The fourth step is to place the enamel coated with the zirconia precursor obtained in the third step in a hydrothermal reaction kettle with 10mL of polytetrafluoroethyle...

Embodiment 2

[0042] Preparation method of titanium oxide restoration layer with tight connection with enamel

[0043] In the first step, add 10mL of distilled water and 90mL of ethylene glycol into the beaker, stir in a water bath at 20°C for 10 minutes until the temperature is stable, add glycine / concentrated hydrochloric acid buffer pair, in which glycine is 0.376g, concentrated HCl is 140 microliters, The reaction pH was maintained at around 3.0;

[0044] In the second step, add 25 microliters of TiCl to the solution prepared in the first step 4 Liquid, stir at 25°C for 10 minutes until completely dissolved;

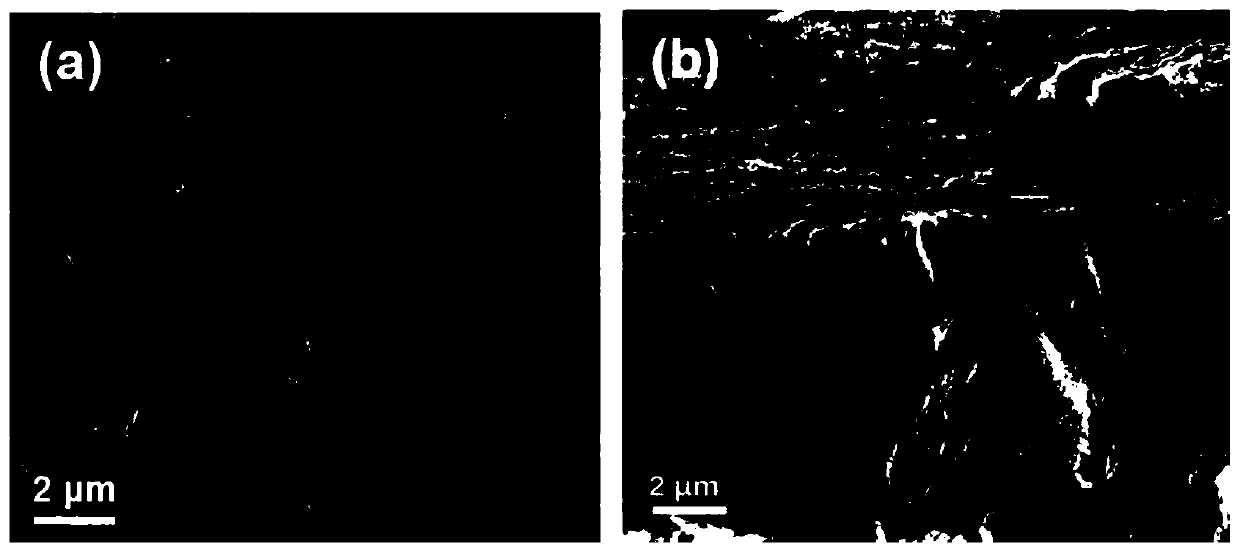

[0045] In the third step, the damaged enamel slice to be repaired is placed in the solution prepared in the second step, and continuously stirred for 4 hours to obtain the enamel coated with the titanium oxide precursor;

[0046] The fourth step is to place the titanium oxide precursor-coated enamel obtained in the third step in a hydrothermal reaction kettle with 10mL of polyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com