Modified corn husk-reinforced polyethylene mulch film

A corn coat and polyethylene technology, applied in plant protection, application, horticulture, etc., can solve the problems of white pollution and poor degradability, and achieve the effects of promoting degradation performance, good tear strength and improving degradation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

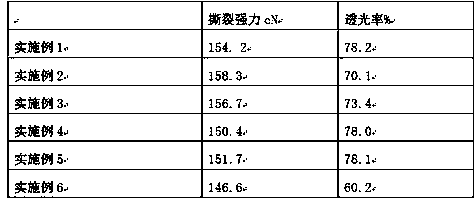

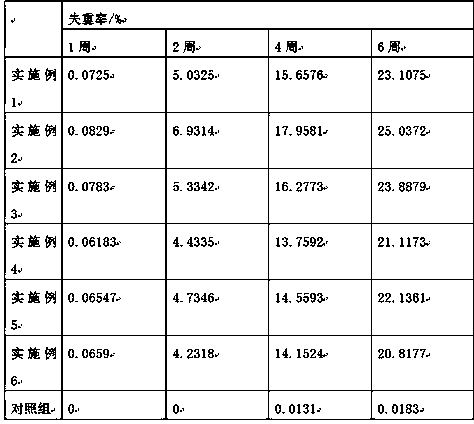

Examples

Embodiment 1

[0023] A modified corn husk reinforced polyethylene mulch, the polyethylene mulch comprising corn husk nanofibrils and submicron inorganic powder composites;

[0024] The corn husk nanofibril and submicron inorganic powder composite is made of corn husk nanofibril and submicron inorganic powder;

[0025] The composite of corn husk nanofibrils and submicron inorganic powder is obtained by adding submicron inorganic powder in a certain step in the preparation process of corn husk nanofibrils.

[0026] Further, the mass proportion of corn coat nanofibrils in the polyethylene film is 33%, and the mass proportion of the submicron inorganic powder is 10%.

[0027] Further, the submicron inorganic powder is perlite with a particle size of 0.2 micron.

[0028] Further, the preparation method of the corn coat nanofibrils is:

[0029] (1) Dry the corn clothes to a moisture content of 8%, then crush them, and pass through a 100-mesh sieve to obtain corn clothes powder;

[0030] (2) Ad...

Embodiment 2

[0038] A modified corn husk reinforced polyethylene mulch, the polyethylene mulch comprising corn husk nanofibrils and submicron inorganic powder composites;

[0039] The corn husk nanofibril and submicron inorganic powder composite is made of corn husk nanofibril and submicron inorganic powder;

[0040] The composite of corn husk nanofibrils and submicron inorganic powder is obtained by adding submicron inorganic powder in a certain step in the preparation process of corn husk nanofibrils.

[0041] Further, the mass proportion of corn coat nanofibrils in the polyethylene film is 35%, and the mass proportion of the submicron inorganic powder is 12%.

[0042] Further, the submicron inorganic powder is perlite with a particle size of 0.2 micron.

[0043] Further, the preparation method of the corn coat nanofibrils is:

[0044] (1) Dry the corn clothes to a moisture content of 8%, then crush them, and pass through a 100-mesh sieve to obtain corn clothes powder;

[0045] (2) Ad...

Embodiment 3

[0053] A modified corn husk reinforced polyethylene mulch, the polyethylene mulch comprising corn husk nanofibrils and submicron inorganic powder composites;

[0054] The corn husk nanofibril and submicron inorganic powder composite is made of corn husk nanofibril and submicron inorganic powder;

[0055] The composite of corn husk nanofibrils and submicron inorganic powder is obtained by adding submicron inorganic powder in a certain step in the preparation process of corn husk nanofibrils.

[0056] Further, the mass proportion of corn coat nanofibrils in the polyethylene mulch film is 32%, and the mass proportion of the submicron inorganic powder is 11%.

[0057] Further, the submicron inorganic powder is perlite with a particle size of 0.2 micron.

[0058] Further, the preparation method of the corn coat nanofibrils is:

[0059] (1) Dry the corn clothes to a moisture content of 8%, then crush them, and pass through a 100-mesh sieve to obtain corn clothes powder;

[0060] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com