A kind of high temperature resistant injection molding polypropylene material and its preparation method and application

A polypropylene material and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant injection-molded polypropylene material and its preparation, can solve problems such as rapid thermal decomposition, achieve reduced production cycle, extensive economic and social benefits, excellent mechanical properties and long-term effect Effect of Heat Aging Properties

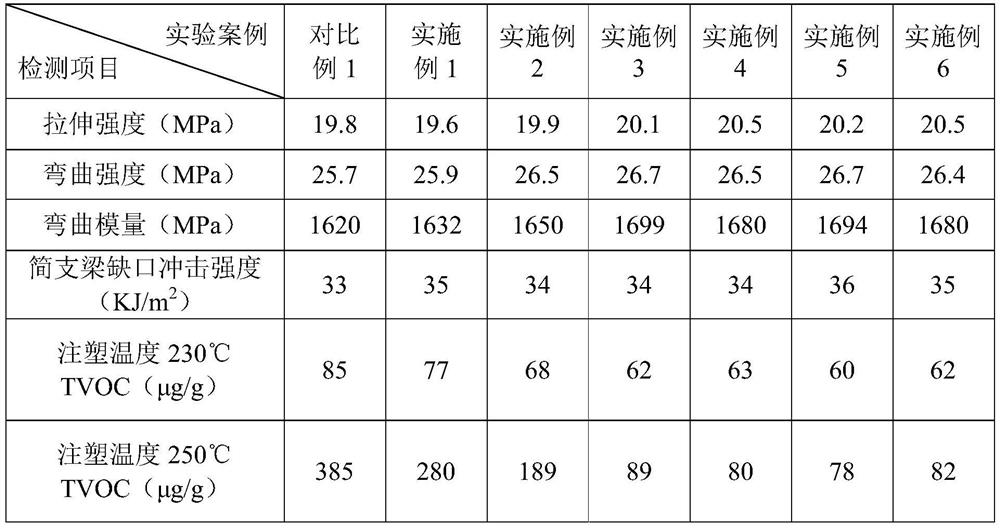

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. For the experimental methods without specific conditions indicated in the following examples, the conventional conditions or the conditions suggested by the manufacturer are usually followed.

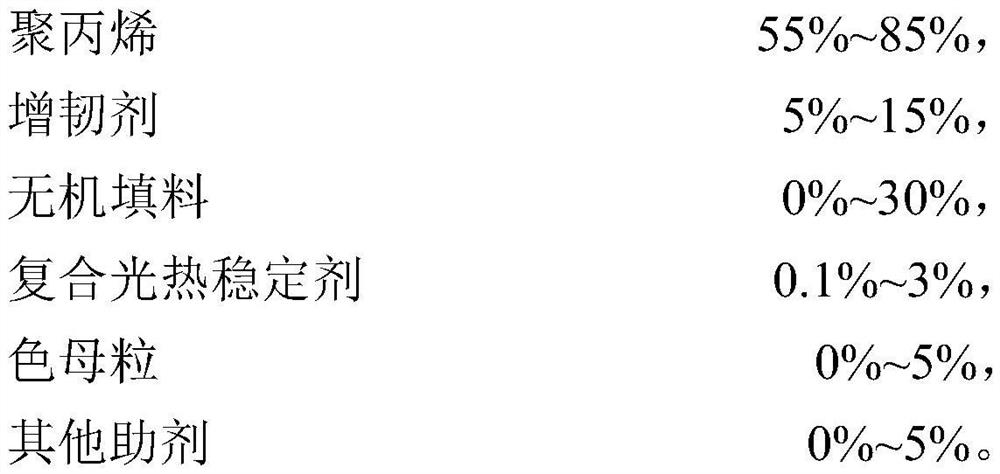

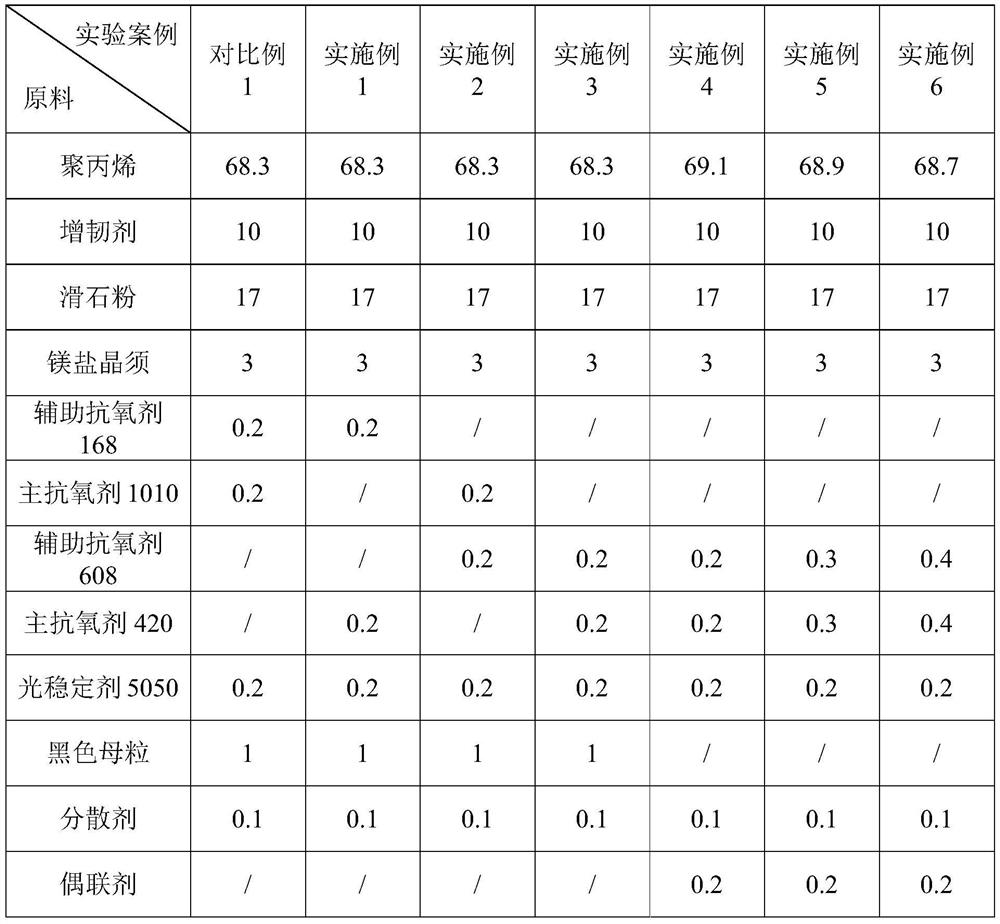

[0036] The raw material formulations of the injection-molded polypropylene materials of the following Examples 1 to 6 and Comparative Example 1 are shown in Table 1, wherein the polypropylene is a copolymerized PP produced by Yanshan Petrochemical Company, the trade name is K7760, and the melt flow rate is 60g / 10min; the toughening agent is ethylene-octene copolymer (POE) produced by Dow Company of the United States, the trade name is ENGAGE 8150, and the density is 0.863g / cm 3 , the melt flow rate is 0.5g / 10min; talc powder is produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com