Pickle fermentation process and equipment capable of controlling reproduction of lactobacillus

A technology of fermentation equipment and lactic acid bacteria, which is applied in the direction of specific-purpose bioreactor/fermenter, biochemical equipment and method, combination of bioreactor/fermenter, etc. rate and other issues, to achieve the effects of inhibiting reproductive growth, preventing total acid from exceeding the standard, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

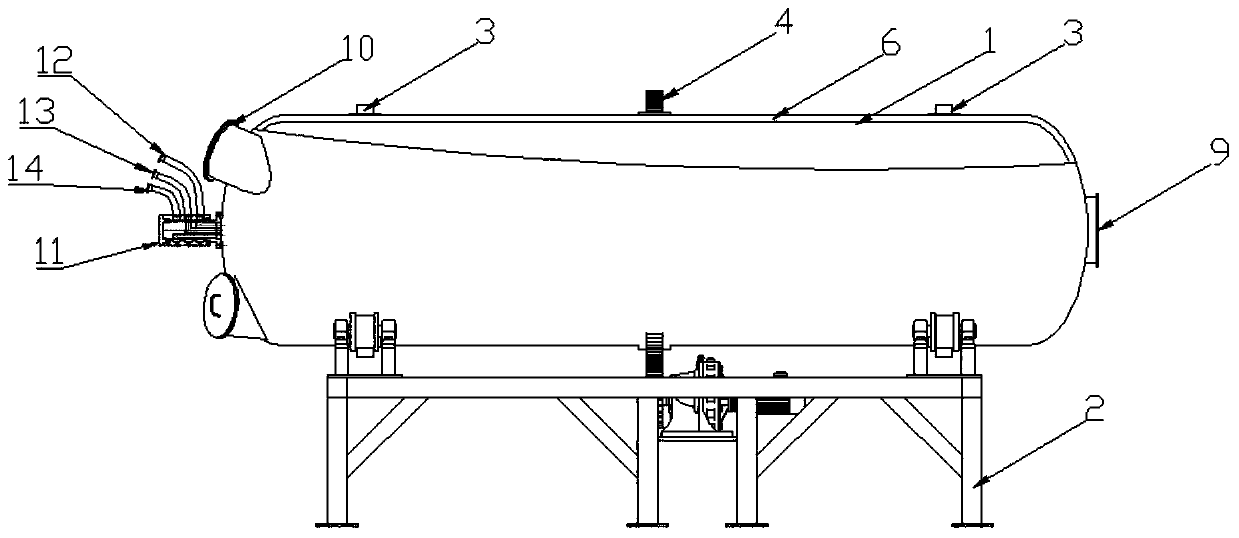

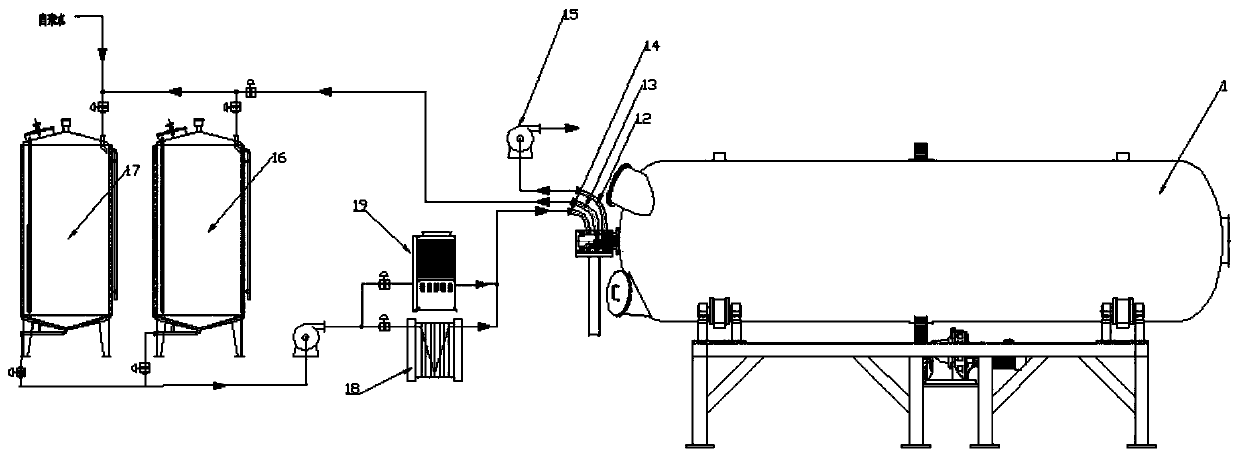

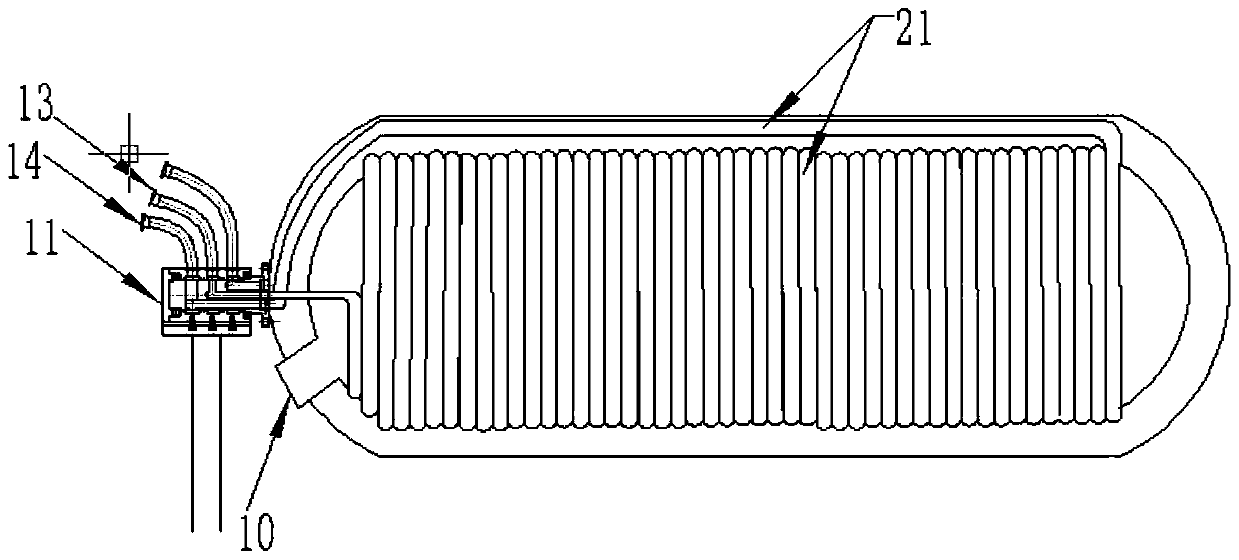

[0039] Embodiment: the pickle fermenting equipment that controls the propagation of lactic acid bacteria

[0040] The equipment of the present invention includes a rotatable cylinder (1), the inner wall of the cylinder (1) is provided with a large helical blade (7) in the axial direction; the large helical blade (7) is provided with a connecting column (5) ) connected small helical blade (8); the helical direction of the large helical blade (7) and the small helical blade (8) is opposite; the cylinder (1) is provided with a jacket (6); the jacket One end of (6) is provided with rotary joint (11); Described rotary joint (11) is provided with vacuum tube (12), and one end of described vacuum tube (12) stretches in cylinder body (1) and nozzle is upward, The other end is connected with vacuum pump (15). The direction of rotation of the large helical blade (7) is toward the discharge port (10), and the direction of rotation of the small helical blade (8) is toward the direction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com