Sulfur-tolerant shift catalyst modified by titanium compound containing sulfate ion and preparation method thereof

A technology of sulfur-resistant conversion and titanium compounds, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of simple preparation process, low cost, and improved anti-hydration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

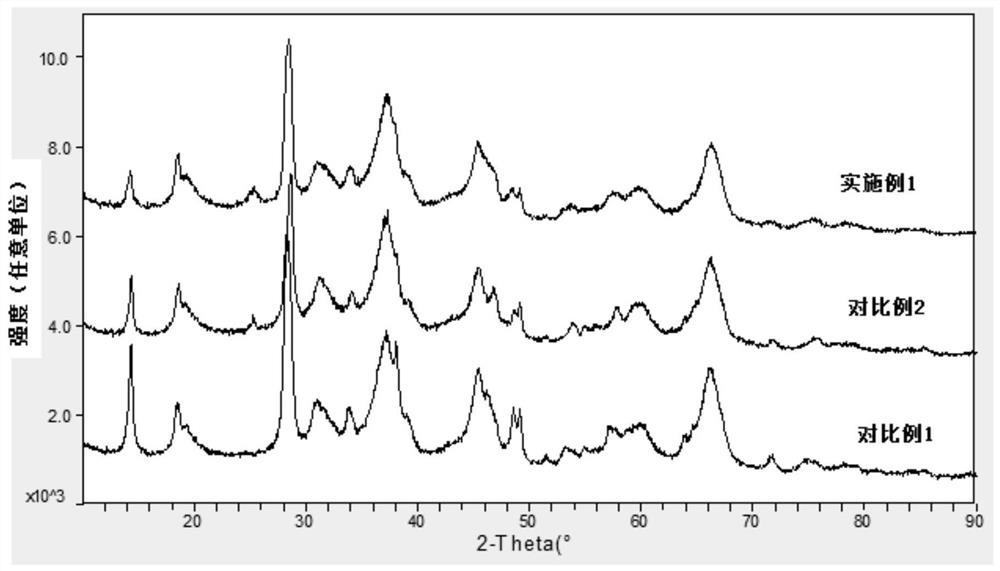

Image

Examples

preparation example Construction

[0034] The present invention has no particular limitation on the preparation method of the sulfur-tolerant shift catalyst, as long as the above-mentioned catalyst can be obtained, any preparation method can be used in the present invention.

[0035] A second aspect of the present invention provides a method for preparing a sulfur-tolerant shift catalyst, the method comprising the following steps:

[0036] (1) The carrier is impregnated in the solution containing the coagent precursor and the titanium compound component containing sulfate ions, followed by drying and roasting;

[0037] (2) Immersing the product obtained in step (1) in a solution containing the precursor of the metal active component, followed by drying and calcining in sequence to obtain the sulfur-tolerant shift catalyst.

[0038] A third aspect of the present invention provides a method for preparing a preferred sulfur-tolerant shift catalyst, the method comprising the following steps:

[0039] (1) impregnat...

Embodiment 1

[0071] This example is used to illustrate the sulfur-tolerant shift catalyst provided by the present invention and its preparation method

[0072] Weigh 1.2g of industrial grade titanyl sulfate, 6.5g of magnesium nitrate, and 0.6g of lanthanum nitrate, dissolve in deionized water, impregnate isometrically on 15.5g of alumina balls, dry at room temperature, dry at 120°C for 12h, and roast at 500°C 3h, the modified carrier was obtained.

[0073] Weigh 2.0g of ammonium heptamolybdate and dissolve it with ammonia water, add 1.9g of citric acid and 2.5g of cobalt acetate, stir and dissolve to prepare a co-impregnation solution, then carry out isovolumic impregnation, dry at room temperature, dry at 12°C for 12h, and roast at 500°C 3h, the sulfur-tolerant shift catalyst was obtained.

[0074] The composition of the catalyst is: 77.5% by weight carrier, 3.2% by weight Co 2 o 3 , 8.0 wt% MoO 3 , 5.1% by weight MgO, 0.7% by weight La 2 o 3 and 5.5% by weight titanyl sulfate.

[...

Embodiment 2

[0094] This example is used to illustrate the sulfur-tolerant shift catalyst provided by the present invention and its preparation method

[0095] Weigh 0.45g of industrial-grade titanyl sulfate, 7.6g of magnesium nitrate, and 1.3g of lanthanum nitrate, dissolve them in deionized water, impregnate isometrically on 16.7g of alumina balls, dry at room temperature, dry at 100°C for 8h, and roast at 400°C 5h, the modified carrier was obtained.

[0096] Weigh 1.25g of ammonium heptamolybdate and dissolve it with ammonia water, add 1.8g of citric acid and 0.63g of basic cobalt carbonate, stir and dissolve to prepare a co-immersion water soaking solution, then carry out isovolumic impregnation, dry at room temperature and then dry at 150°C for 10h. Calcined at 600°C for 3 hours to obtain a sulfur-tolerant shift catalyst.

[0097] The composition of the catalyst is: 83.5% by weight carrier, 2% by weight Co 2 o 3 , 5 wt% MoO 3 , 6 wt% MgO, 1.5 wt% La 2 o 3 and 2% by weight titany...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com