Poplar steam blasting liquid hemicellulose-based hydrogel and preparation method thereof

A technology of hemicellulose and hydrogel, which is applied in poplar wood steam explosion liquid hemicellulose-based hydrogel and its preparation field, can solve the problems of poor water retention performance, poor environmental protection performance and poor treatment effect of hydrogel, etc. Achieve excellent water retention performance, less environmental pollution, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The poplar wood steam explosion liquid hemicellulose-based hydrogel described in this embodiment is a three-dimensional network structure polymer formed by graft copolymerization of hemicellulose in the poplar wood steam explosion liquid with acrylamide and acrylic acid. The mass ratio of cellulose, acrylamide and acrylic acid is 1:1.3:3.6.

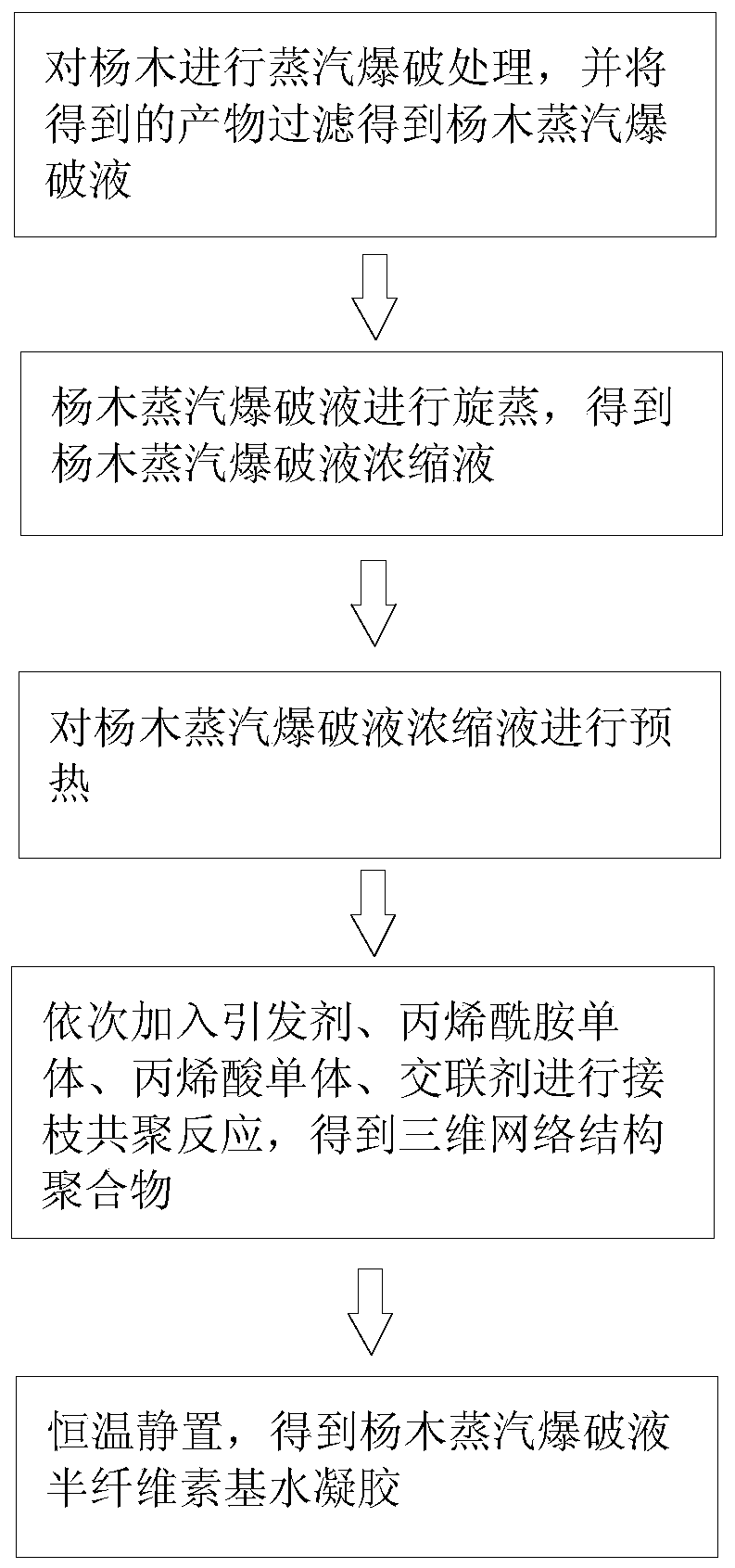

[0037] The preparation method of the poplar steam explosion liquid hemicellulose-based hydrogel described in the present embodiment is as follows:

[0038] S1. Immerse the poplar wood in a sealed bag with distilled water for rehydration balance, control the water content at about 35%, put it in a refrigerator at 6°C, and balance it for 48 hours; put the rehydrated and balanced poplar wood chips into the high pressure reaction In the autoclave, steam is introduced into the autoclave first, so that the temperature rises to 209°C, then heat preservation is carried out, and the pressure is maintained. The pressure maintenance time is 7...

Embodiment 2

[0045] The poplar wood steam explosion liquid hemicellulose-based hydrogel described in this embodiment is a three-dimensional network structure polymer formed by graft copolymerization of hemicellulose in the poplar wood steam explosion liquid with acrylamide and acrylic acid. The mass ratio of cellulose, acrylamide and acrylic acid is 1:1.4:3.

[0046] The preparation method of the poplar steam explosion liquid hemicellulose-based hydrogel described in the present embodiment is as follows:

[0047] S1. Immerse the poplar wood in a sealed bag with distilled water for rehydration balance, control the water content at about 35%, put it in a refrigerator at 6°C, and balance it for 48 hours; put the rehydrated and balanced poplar wood chips into the high pressure reaction In the autoclave, steam is introduced into the autoclave first, so that the temperature rises to 209°C, then heat preservation is carried out, and the pressure is maintained. The pressure maintenance time is 7 m...

Embodiment 3

[0053] The poplar wood steam explosion liquid hemicellulose-based hydrogel described in this embodiment is a three-dimensional network structure polymer formed by graft copolymerization of hemicellulose in the poplar wood steam explosion liquid with acrylamide and acrylic acid. The mass ratio of cellulose, acrylamide and acrylic acid is 1:1:4.

[0054] The preparation method of the poplar steam explosion liquid hemicellulose-based hydrogel described in the present embodiment is as follows:

[0055] S1. Immerse the poplar wood in a sealed bag with distilled water for rehydration balance, control the water content at about 35%, put it in a refrigerator at 6°C, and balance it for 48 hours; put the rehydrated and balanced poplar wood chips into the high pressure reaction In the autoclave, steam is introduced into the autoclave first, so that the temperature rises to 209°C, then heat preservation is carried out, and the pressure is maintained. The pressure maintenance time is 7 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com