Preparation method of low-glycemic-index rice noodles

A technology of low glycemic index and rice noodles, applied in the field of preparation of low glycemic index rice noodles, can solve the problems of not achieving the desired effect, loss of slow digestion characteristics, crystal transformation, etc., and achieve easy large-scale industrial production and high complexation rate The effect of improving and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

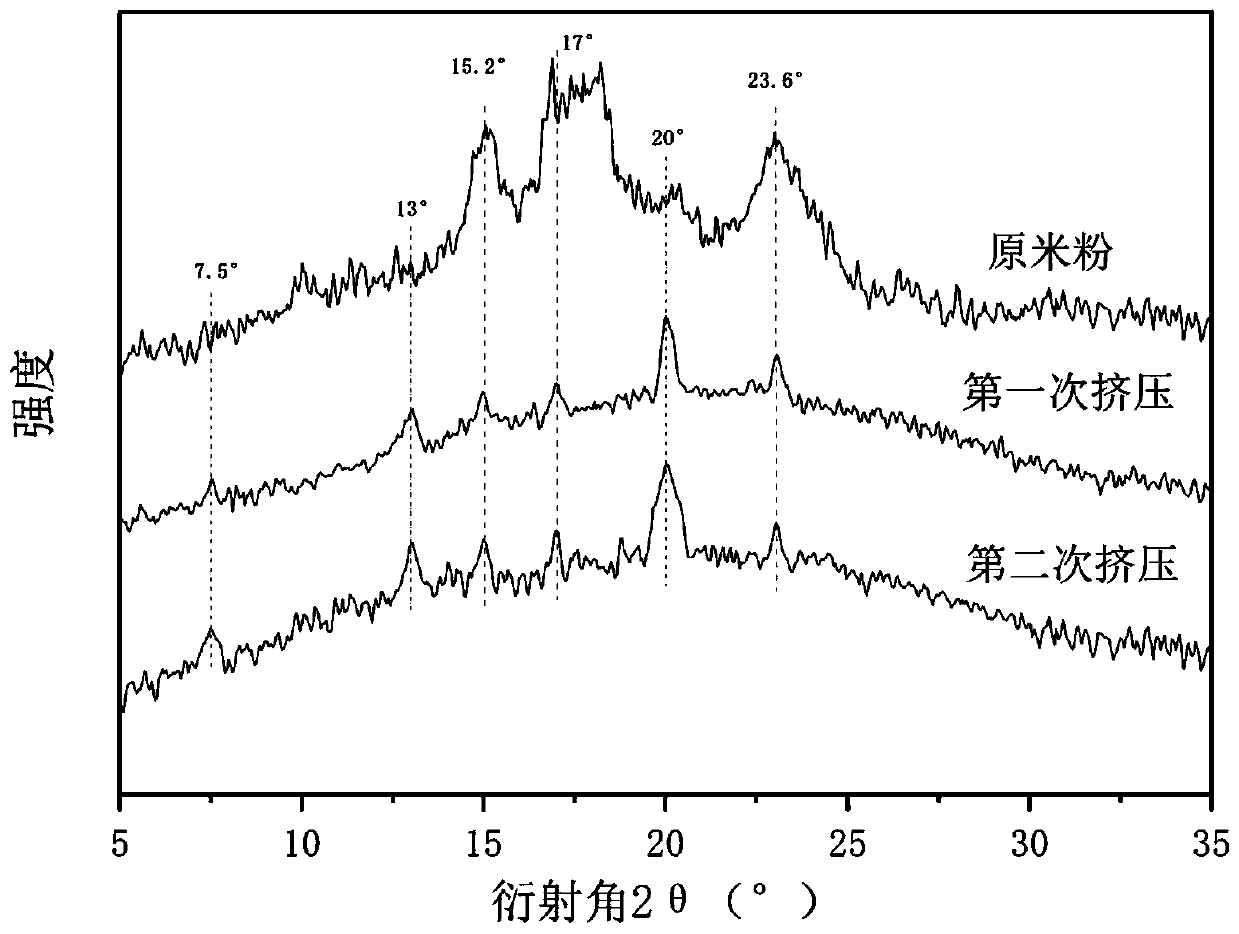

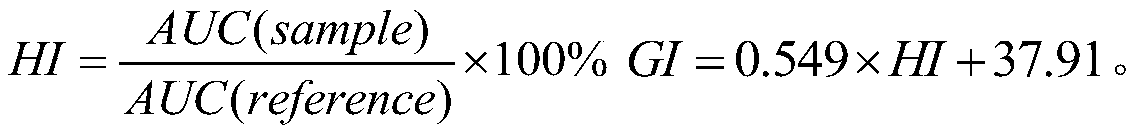

Method used

Image

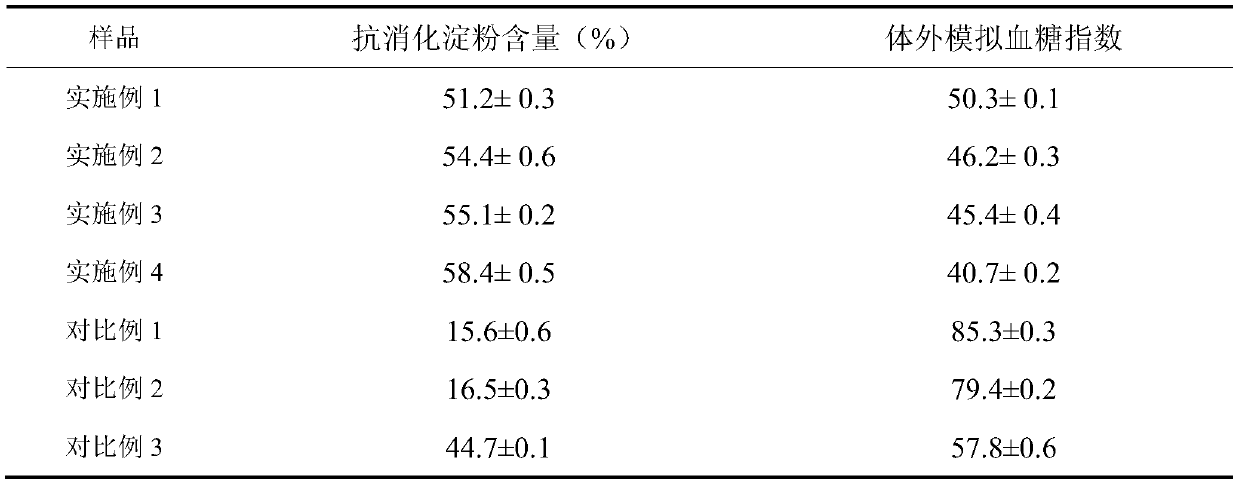

Examples

Embodiment 1

[0040] Embodiment 1: Preparation of low glycemic index anti-digestion rice noodles

[0041] details as follows:

[0042] (1) Pass the rice starch through a 100-mesh sieve, add water to adjust to a water content of 30% to 35%, and set aside;

[0043] (2) Add debranching enzyme and emulsifier to rice starch raw material, mix uniformly; Wherein, debranching enzyme is pullulanase and isoamylase, and addition is 40ASPU / g rice starch dry basis, pullulanase and The dosage ratio of isoamylase is 1:1; the emulsifier is glycerol monostearate, and the total addition amount is 0.5% (w / w) of the rice starch raw material; the water content is adjusted to 30% to 35%;

[0044] (3) Send the mixture into the extruder, the solid feeding speed is 5t / h before the extrusion starts, set the temperature of the four sections of the extruder to 45°C, 55°C, 65°C, 75°C respectively, the screw The rotating speed is 80rpm, and the die head aperture of the discharge port of the extruder is 8mm;

[0045] ...

Embodiment 2

[0048] Embodiment 2: Preparation of low glycemic index anti-digestion rice noodles

[0049] details as follows:

[0050] (1) Pass the rice starch through a 100-mesh sieve, add water to adjust to a water content of 30% to 35%, and set aside;

[0051] (2) Add debranching enzyme and emulsifier to rice starch raw material, mix uniformly; Wherein, debranching enzyme is pullulanase and isoamylase, and addition is 45ASPU / g rice starch dry basis, pullulanase and The dosage ratio of isoamylase is 1:1; the emulsifier is glycerol monostearate, and the total addition amount is 0.5% (w / w) of the rice starch raw material; the water content is adjusted to 30% to 35%;

[0052] (3) Send the mixture into the extruder, the solid feeding speed is 6t / h before the extrusion starts, set the temperature of the four sections of the extruder to 50°C, 60°C, 70°C, 80°C respectively, the screw The rotating speed is 90rpm, and the die head aperture of the discharge port of the extruder is 8mm;

[0053] ...

Embodiment 3

[0056] Embodiment 3: Preparation of low glycemic index anti-digestion rice noodles

[0057] details as follows:

[0058] (1) Pass the rice starch through a 100-mesh sieve, add water to adjust to a water content of 30% to 35%, and set aside;

[0059] (2) Add pullulanase and emulsifier to the rice starch raw material, and mix evenly; wherein, the debranching enzyme is pullulanase and isoamylase, and the addition amount is 50 ASPU / g rice starch dry basis, pullulan The dosage ratio of enzyme and isoamylase is 1:1; the emulsifier is glycerol monostearate, and the total addition amount is 1% (w / w) of the rice starch raw material; the water content is adjusted to 30% to 35%;

[0060] (3) Send the mixture into the extruder, the solid feeding speed is 7t / h before the extrusion starts, set the temperature of the four sections of the extruder to 55°C, 65°C, 75°C, 85°C respectively, the screw The rotating speed is 100rpm, and the die head aperture of the discharge port of the extruder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com