Efficient leakage-proof water-loaded capsule and preparation method thereof

An anti-leakage and capsule technology, which is applied in capsule delivery, preparation of tobacco, medical preparations of non-active ingredients, etc., can solve problems such as unsatisfactory forming degree, unsatisfactory water blocking effect, and easy penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

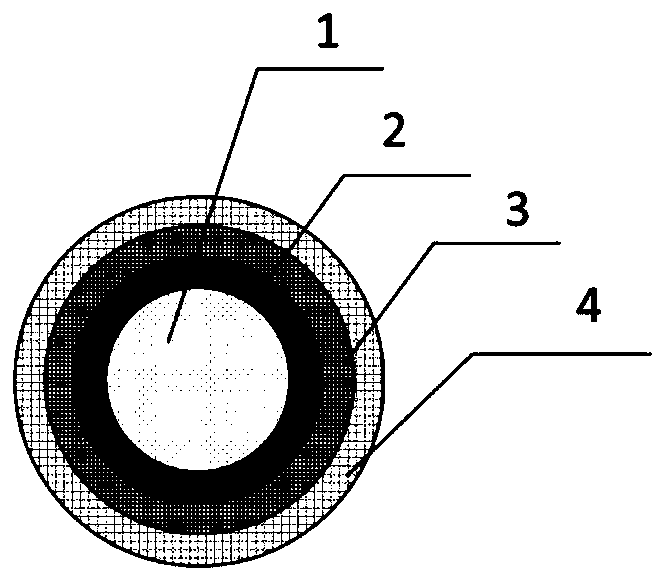

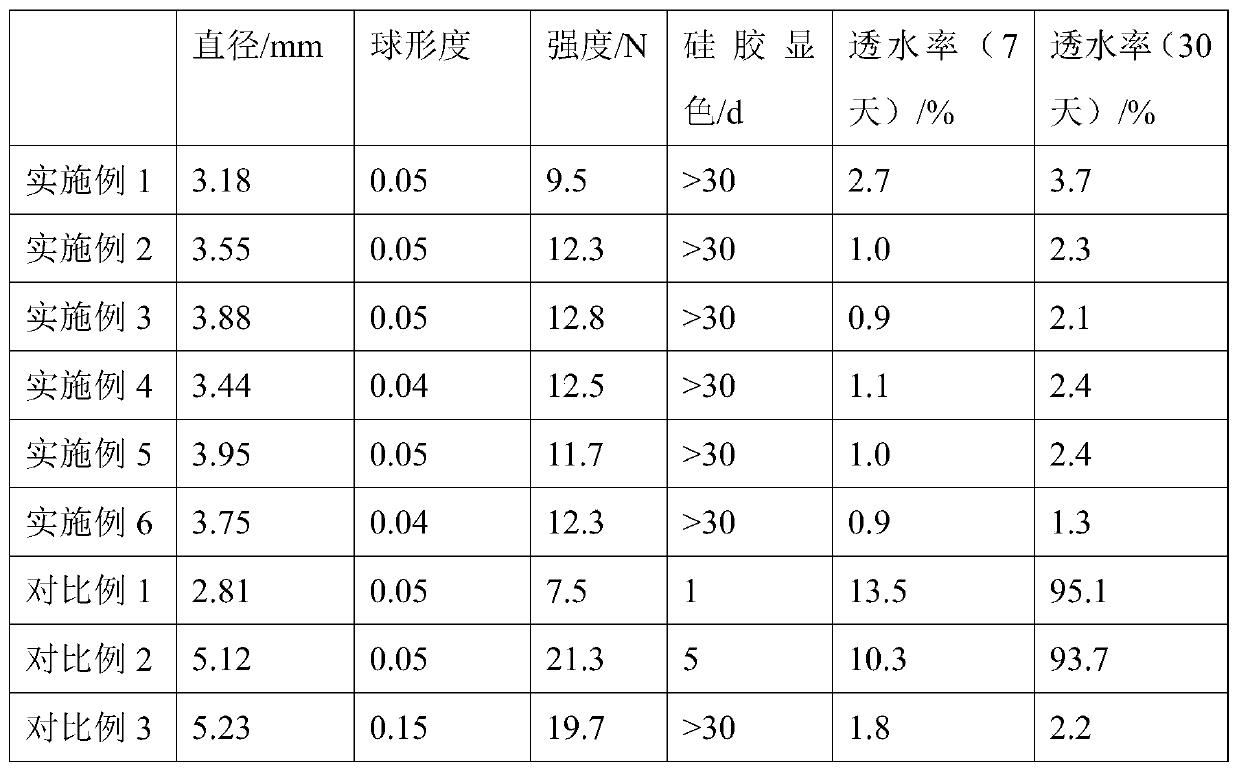

[0035] A preparation method of a high-efficiency anti-leakage water-carrying capsule, which is produced according to the following steps: preparing a core layer, the core layer is a calcium chloride aqueous solution with a concentration of 10%; preparing a capsule wall layer, and the raw material of the capsule wall layer is sodium alginate solution , the concentration is 3%; the first water blocking layer is prepared, and the first water blocking layer is cyanoacrylate. The operation steps are as follows: (1) preparing capsules by back-dropping method, the core layer is calcium chloride aqueous solution, and the raw material of capsule wall layer is sodium alginate solution; (2) the capsules obtained in step (1) are dispersed in dimethyl carbonate, The cyanoacrylate was added dropwise to the dispersion system until the first water-blocking layer was formed on the surface of the capsule. In order to ensure the fluidity of the sodium alginate when preparing the capsules, the te...

Embodiment 2

[0037] A preparation method of a high-efficiency anti-leakage water-carrying capsule, which is produced according to the following steps: prepare a core layer, the core layer is a mixed solution of water, essence and calcium chloride, the concentration of essence is 20%, and the concentration of calcium chloride solution is 10%; prepare the wall layer, the raw material of the wall layer is sodium alginate solution, the concentration is 3%; prepare the first water blocking layer, the first water blocking layer is cyanoacrylate; prepare the second water blocking layer, the second The water blocking layer is a mixed solution of photocurable resin monomer and initiator. The operation steps are as follows: (1) Capsules are prepared by the reverse drop method, the core layer is a mixed solution of water, essence and calcium chloride, and the raw material of the capsule wall layer is sodium alginate solution; (2) The surface of the capsule is coated with the first water-blocking layer...

Embodiment 3

[0039] A preparation method of a high-efficiency anti-leakage water-carrying capsule, which is produced according to the following steps: prepare a core layer, the core layer is a mixed solution of water, essence and calcium chloride, the concentration of essence is 20%, and the concentration of calcium chloride solution is 10% %; prepare the wall layer, the raw material of the wall layer is sodium alginate solution, the concentration is 3%; prepare the first water-blocking layer, the first water-blocking layer is cyanoacrylate; prepare the second water-blocking layer, the second water-blocking layer The water layer is a mixed solution of photocurable resin monomer and initiator. The operation steps are as follows: (1) Capsules are prepared by the reverse drop method, the core layer is a mixed solution of water, essence and calcium chloride, and the raw material of the capsule wall layer is sodium alginate solution; (2) The surface of the capsule is coated with the first water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com