Thermoforming mold cooling process and thermoforming mold thereof

A technology of mold cooling and cooling process, applied in the direction of forming tools, manufacturing tools, heat treatment equipment, etc., can solve the problems of no water leakage in thermoforming molds, high price of high-strength steel thermoforming molds, and increased mold manufacturing costs and maintenance costs, etc. To achieve the effect of saving processing time, reducing processing workload, reducing manufacturing cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

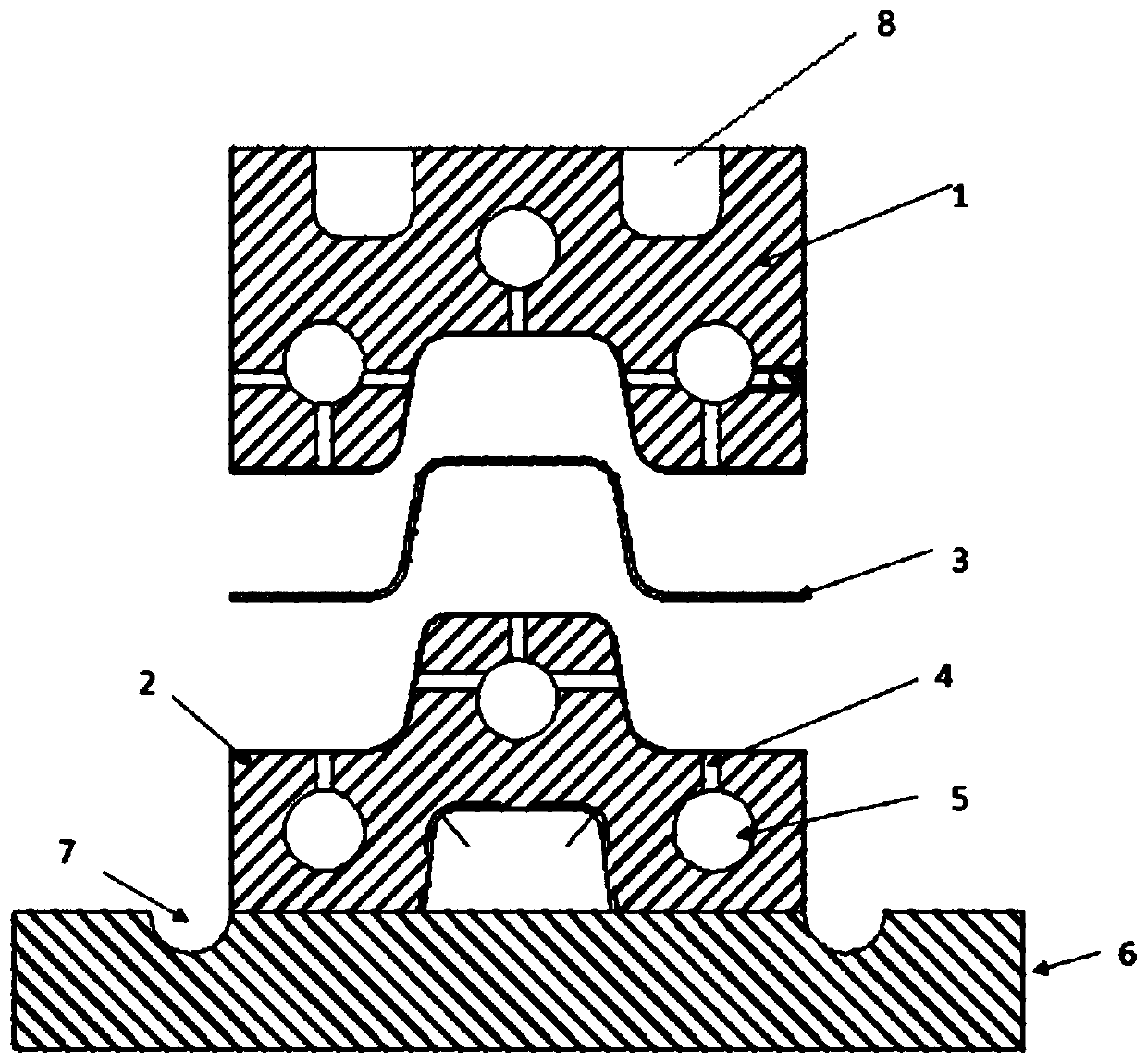

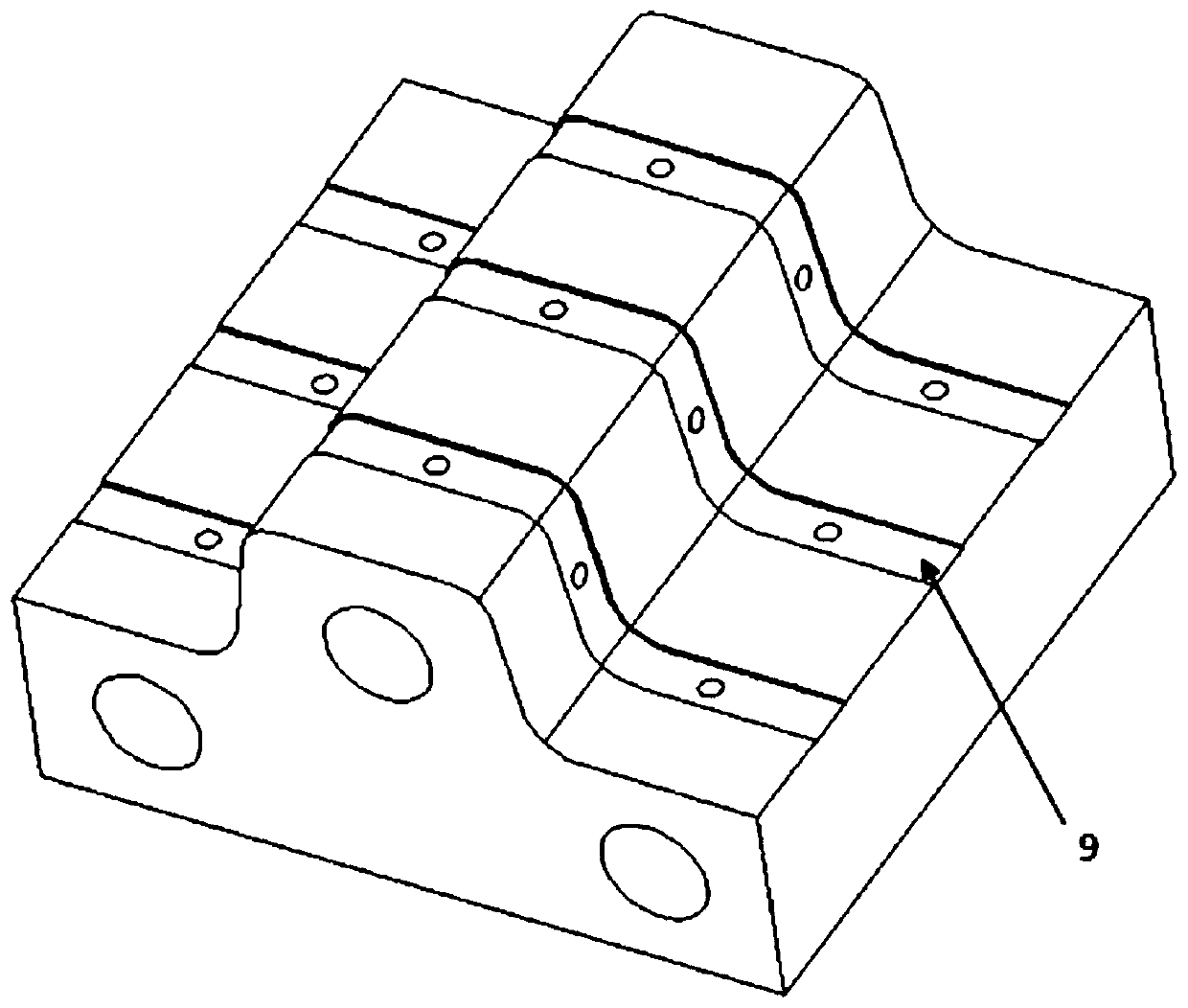

[0036] Such as Figure 1-2 As shown, a thermoforming mold includes an upper mold core 1 , a lower mold core 2 , and a casting backing plate 6 , and the upper mold core 1 and the lower mold core 2 are provided with casting lightening holes 8 . Part 3 is in the middle of the mold.

[0037] The upper mold core 1 and the lower mold core 2 use cast steel: reduce the amount of processing and reduce the cost of steel blocks

[0038] The main water hole 5 is directly cast: when the mold is closed, water or water mist flows through the main water pipe, and the water or water mist enters the groove (through the water tank) 9 through the small water hole 4; the water or water mist flows in the groove so that Take away the heat of the workpiece to achieve the purpose of cooling and quenching of the workpiece 3.

[0039] Small water hole 4: arranged horizontally or vertically to reduce the difficulty of machining.

[0040] A drain groove 7 is opened on the casting backing plate 6, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com