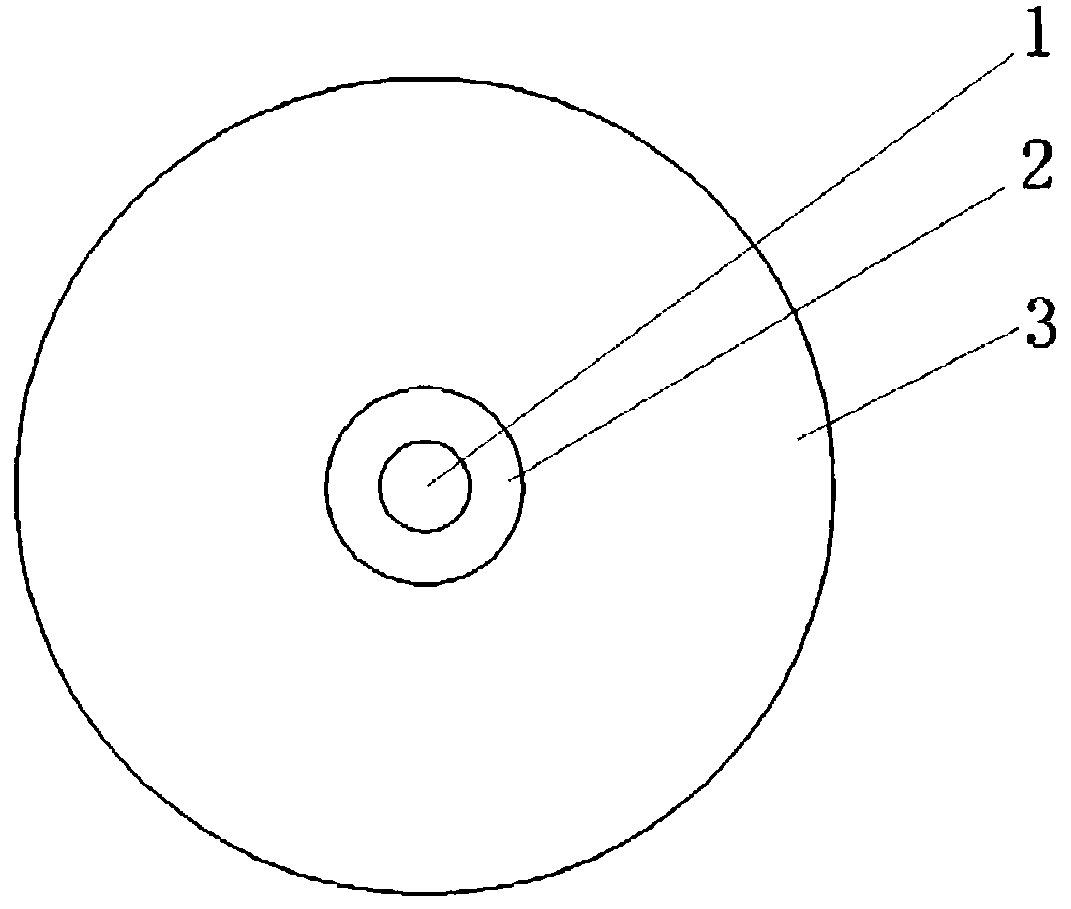

A kind of tm/tb co-doped silica fiber for 1.7μm fiber laser and its preparation method

A fiber laser and quartz fiber technology, which is applied in the field of optical fiber, can solve the problems of difficult uniform doping and achieve good repeatability, high anti-damage threshold power, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Using chemical vapor deposition method combined with chelate precursor doping technology, the Tm 3+ and Tb 3+ Chelate Tm(thd) 3 and Tb(thd) are uniformly mixed into the deposition layer in the quartz tube in turn to form the preform core layer and the inner cladding layer respectively, and then the outer cladding structure is formed by adjusting the formula composition of the adjacent deposition layer, and finally the optical fiber is formed by high temperature sintering and rod shrinkage process Preform. Among them, the core layer formula components are: Tm(thd) 3 : 0.5%, SiCl 4 : 35%, GeCl 4 : 20%, SiF 4 : 18%, POCl 3 : 20%, AlCl 3 : 6.5%, the inner cladding formula components are: Tb(thd) 3 : 2%, SiCl 4 : 35%, GeCl 4 : 20%, SiF 4 : 18%, POCl 3 : 20%, AlCl 3 : 5%, the outer cladding formula components include: SiCl 4 : 40%, GeCl 4 : 15%, SiF 4 : 30%, POCl 3 : 15%. The deposition temperature is 1300°C, and the pressure difference in the deposition ...

Embodiment 2

[0027] 1) Using chemical vapor deposition method combined with chelate precursor doping technology, the Tm 3+ and Tb 3+ Chelate Tm(thd) 3 and Tb(thd) are uniformly mixed into the deposition layer in the quartz tube in turn to form the preform core layer and the inner cladding layer respectively, and then the outer cladding structure is formed by adjusting the formula composition of the adjacent deposition layer, and finally the optical fiber is formed by high temperature sintering and rod shrinkage process Preform. Among them, the core layer formula components are: Tm(thd) 3 : 1%, SiCl 4 : 40%, GeCl 4 : 18%, SiF 4 : 17%, POCl 3 : 18%, AlCl 3 : 6%, the inner cladding formula component is: Tb(thd) 3 : 1%, SiCl 4 : 40%, GeCl 4 : 18%, SiF 4: 17%, POCl 3 : 18%, AlCl 3 : 6%, the outer cladding formula components include: SiCl 4 : 45%, GeCl 4 : 13%, SiF 4 : 27%, POCl 3 : 15%. The deposition temperature is 1350°C, and the pressure difference in the deposition tube is...

Embodiment 3

[0031] 1) Using chemical vapor deposition method combined with chelate precursor doping technology, the Tm 3+ and Tb 3+ Chelate Tm(thd) 3 and Tb(thd) are uniformly mixed into the deposition layer in the quartz tube in turn to form the preform core layer and the inner cladding layer respectively, and then the outer cladding structure is formed by adjusting the formula composition of the adjacent deposition layer, and finally the optical fiber is formed by high temperature sintering and rod shrinkage process Preform. Among them, the core layer formula components are: Tm(thd) 3 : 2%, SiCl 4 : 50%, GeCl 4 : 15%, SiF 4 : 15%, POCl 3 : 13%, AlCl 3 : 5%, the inner cladding formula component is: Tb(thd) 3 : 0.5%, SiCl 4 : 50%, GeCl 4 : 15%, SiF 4 : 15%, POCl 3 : 13%, AlCl 3 : 6.5%, the outer cladding formula components include: SiCl 4 : 50%, GeCl 4 : 10%, SiF 4 : 25%, POCl 3 : 15%. The deposition temperature is 1450°C, and the pressure difference in the deposition tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com