Mono-crystal strontium titanate substrate with atomic-scale step structure and preparation method of substrate

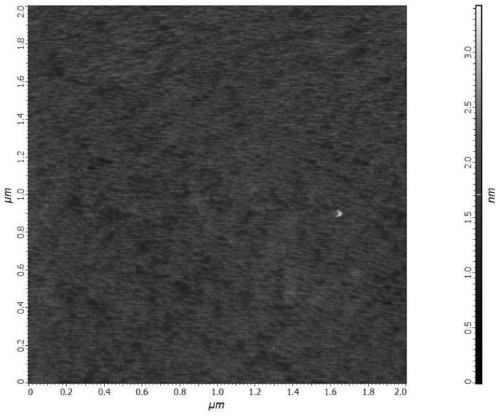

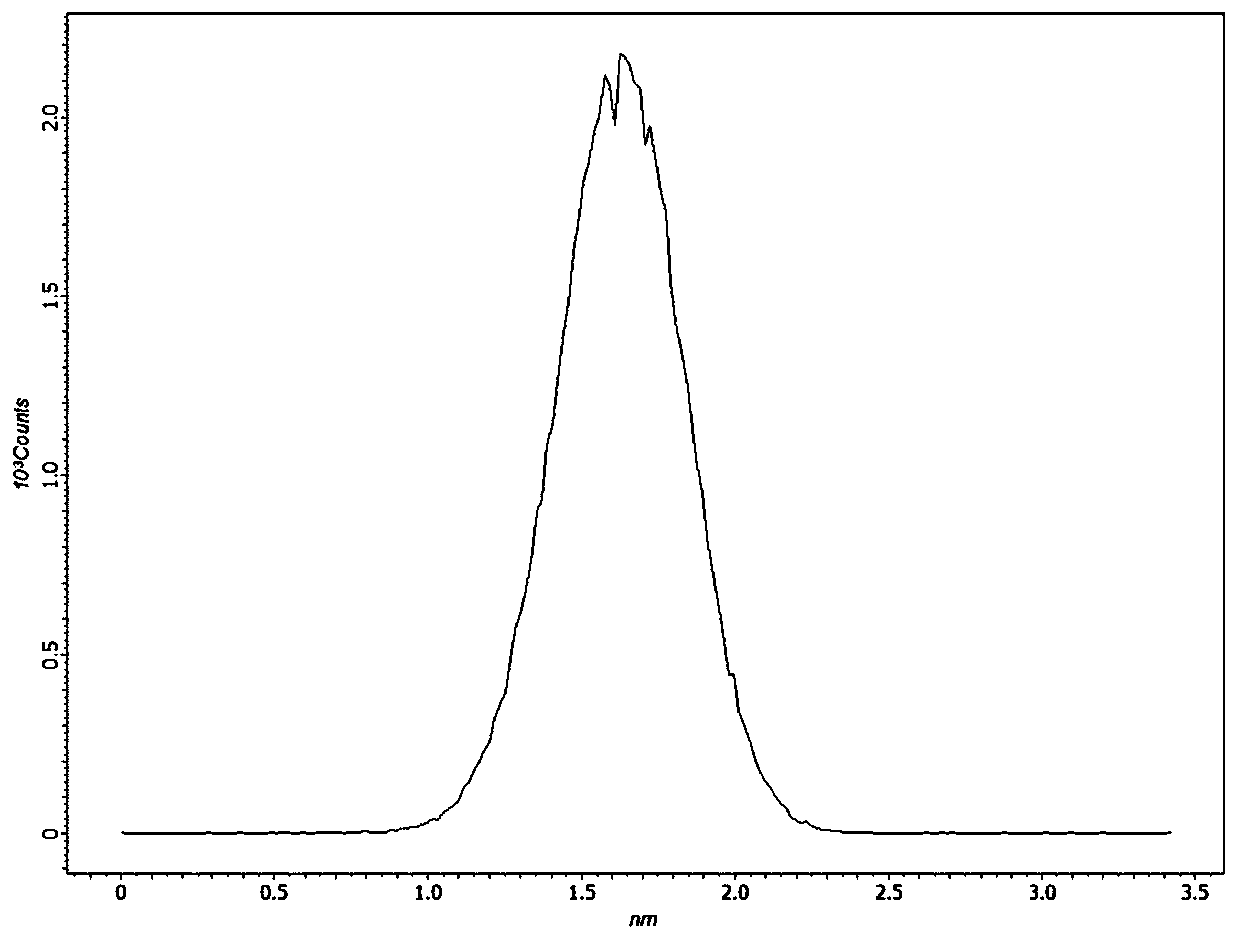

An atomic-level step and substrate substrate technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of unfavorable high-quality functional thin film growth, unexplored chemical reaction time, obvious defects and holes, etc. problem, to achieve the effect of low surface root mean square roughness, suitable annealing time and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

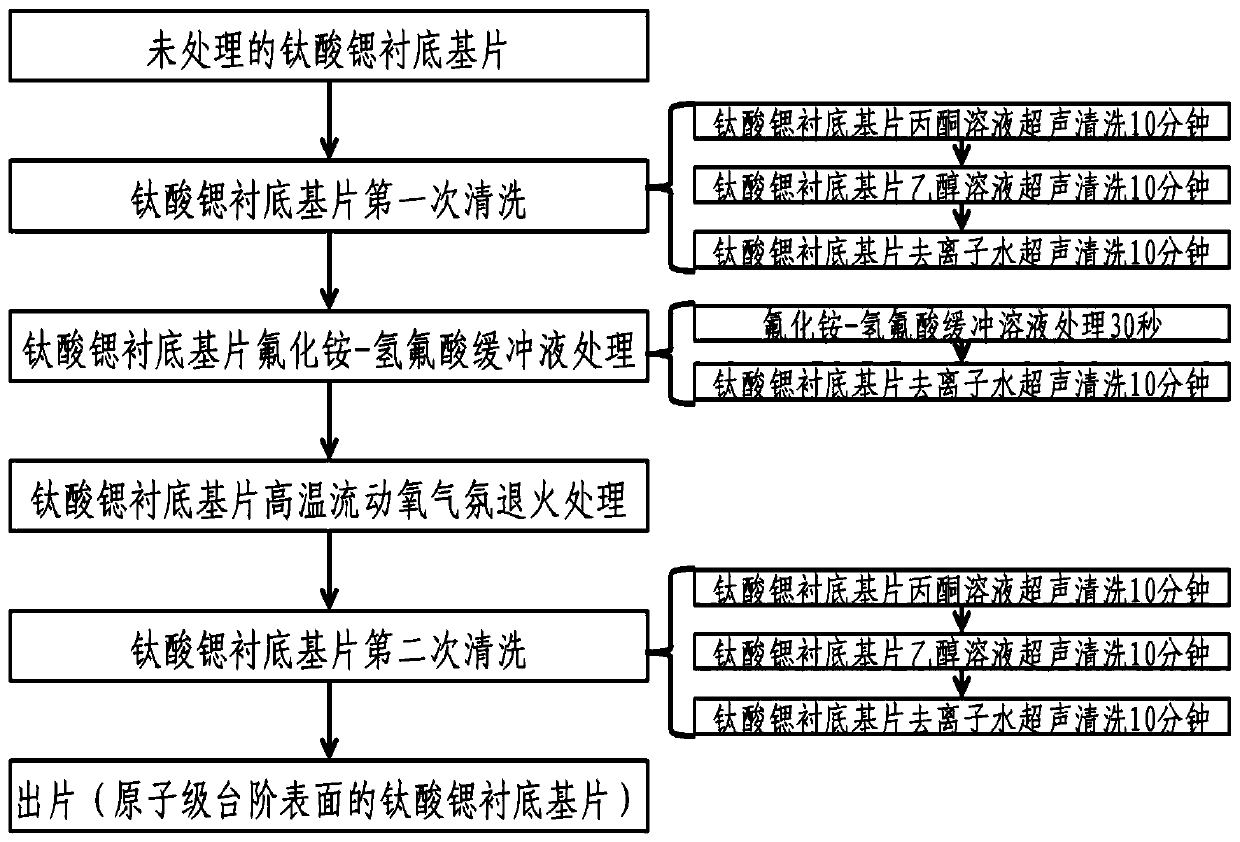

[0049] Embodiment 1: Preparation method of single crystal strontium titanate substrate with atomic-level step structure

[0050] Steps include:

[0051] (1) Ultrasonic cleaning is carried out for the first time on the untreated strontium titanate substrate substrate; the first ultrasonic cleaning includes three steps, and the cleaning steps are as follows: first, the untreated strontium titanate substrate substrate is The chip was ultrasonically cleaned in acetone solution, and the ultrasonic cleaning time of the acetone solution was 10 minutes; then, the strontium titanate substrate substrate cleaned by the acetone solution was ultrasonically cleaned in the ethanol solution, and the ultrasonic cleaning time of the ethanol solution was 10 minutes; finally, The strontium titanate substrate substrate cleaned by the ethanol solution is ultrasonically cleaned in deionized water, and the ultrasonic cleaning time of deionized water is 10 minutes;

[0052] (2) corrode the first clea...

Embodiment 2

[0057] Embodiment 2: Preparation method of single crystal strontium titanate substrate substrate with atomic-level step structure

[0058] Steps include:

[0059] (1) The strontium titanate substrate substrate after the first ultrasonic cleaning in Example 1 is corroded with the ammonium fluoride-hydrofluoric acid buffer solution with a pH value of 4.5 after the first cleaning of the strontium titanate substrate Substrate, etch time is 45s;

[0060] (2) Perform annealing treatment on the obtained strontium titanate substrate substrate under a high-temperature flowing oxygen atmosphere. The conditions for annealing treatment are: place the strontium titanate substrate substrate in a vacuum environment, feed flowing oxygen gas, and control the temperature 950℃, the annealing time is 1h;

[0061] (3) ultrasonically cleaning the strontium titanate substrate substrate after the annealing treatment for the second time, the cleaning method and steps are the same as in Example 1; an...

Embodiment 3

[0063] Embodiment 3: Preparation method of single crystal strontium titanate substrate with atomic-level step structure

[0064] Steps include:

[0065] (1) The strontium titanate substrate substrate after the first ultrasonic cleaning in Example 1 is corroded with the ammonium fluoride-hydrofluoric acid buffer solution with a pH value of 5.5 after the first cleaning of the strontium titanate substrate For the substrate, the etching time is 35s; then, the strontium titanate substrate substrate etched by the buffer solution is ultrasonically cleaned with deionized water for 10 minutes;

[0066] (2) Perform annealing treatment on the obtained strontium titanate substrate substrate under a high-temperature flowing oxygen atmosphere. The conditions for annealing treatment are: place the strontium titanate substrate substrate in a vacuum environment, feed flowing oxygen gas, and control the temperature 1100℃, the annealing time is 1h;

[0067] (3) ultrasonically cleaning the stro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com