Photoelectric hybrid airtight cabin crossing socket

A photoelectric hybrid and airtight technology, which is applied in the direction of electrical components, optical waveguide coupling, and parts of connecting devices, can solve the problem of the inability to simultaneously plug and unplug the electrical and optical fiber contacts, and the optical fiber contacts have long dimensions, The problem of large insertion loss of the airtight socket is achieved to overcome the large insertion loss, reduce the loss of the optical path, and achieve the effect of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

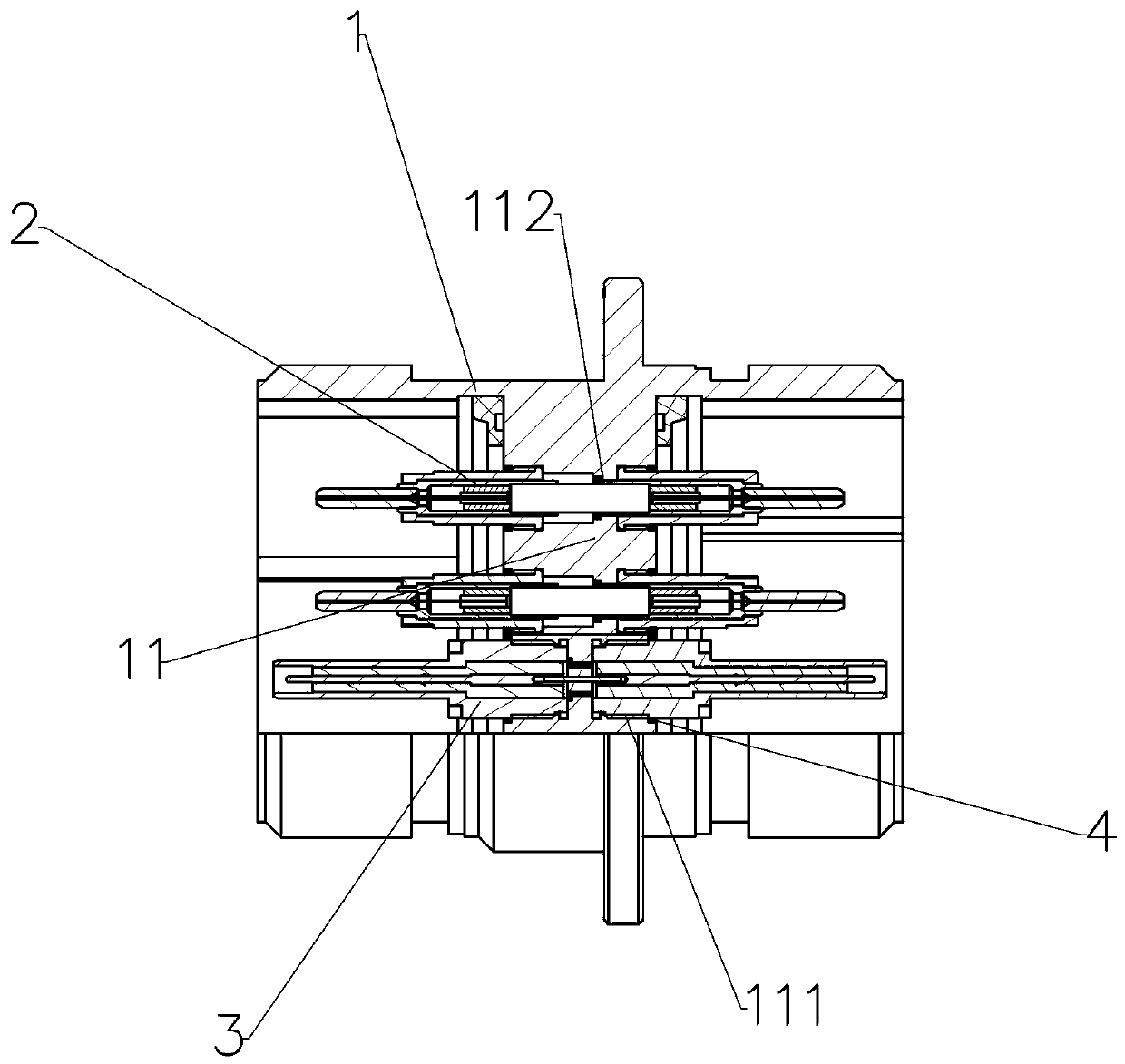

[0026] refer to figure 1 , The present invention includes a shell, 1, an optical fiber ferrule fitting 2 and a radio frequency ferrule fitting 3.

[0027] refer to figure 1 , the housing 1 is a circular housing member, the middle of which is radially provided with a partition wall 11, and the partition wall 11 is provided with several optical fiber pin holes 112 and several radio frequency pin holes 111, and the optical fiber pin holes 112 Both ends are provided with internal threads, and both ends of the radio frequency pin hole 111 are provided with internal threads.

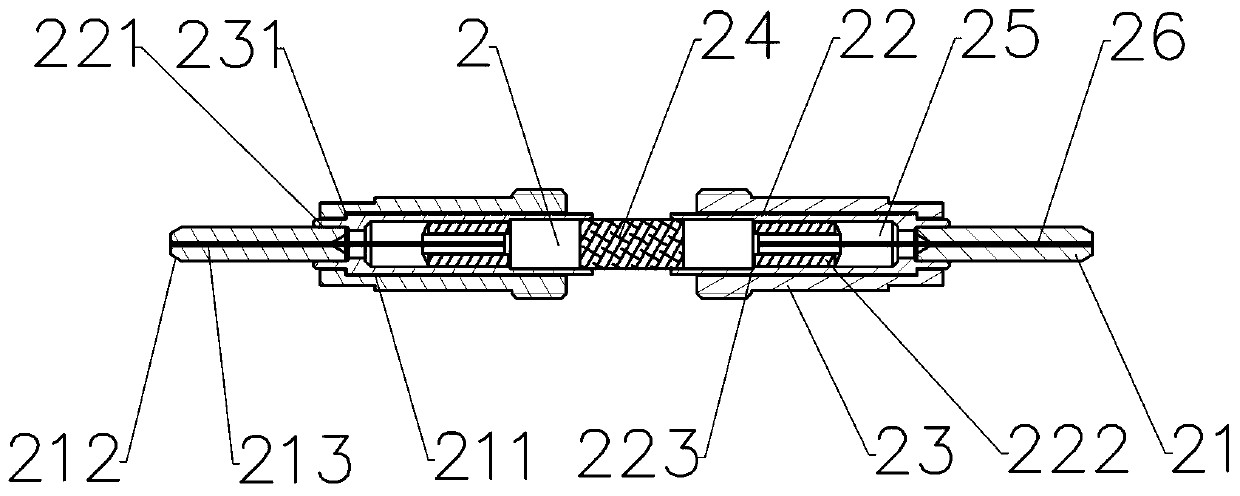

[0028] refer to figure 1 , figure 2 , the optical fiber ferrule assembly 2 is composed of a lens 24 and an optical fiber assembly, wherein the optical fiber assembly is composed of a ceramic sleeve 21, an inner sleeve 22, a coaxial through hole 222, an outer sleeve 23, an optical fiber 26 and an epoxy glue 25, The outer casing 23 is provided with external threads;

[0029] The inner casing 22 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com