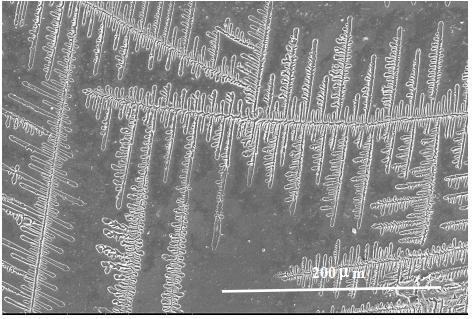

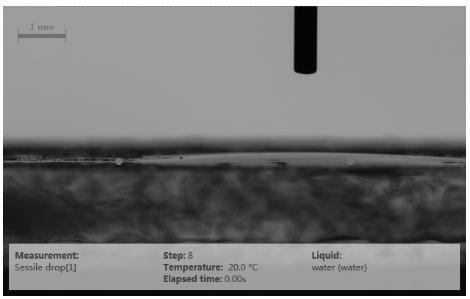

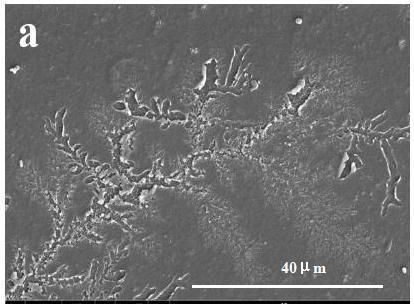

Method for preparing silicon dioxide/titanium dioxide composite film containing branch porous structure on substrate

A technology of silicon dioxide and titanium dioxide, applied in the coating and other directions, can solve the problems of super hydrophilic effect failure and other problems, and achieve the effect of good wear resistance, unique design and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Surface polishing: the ordinary float glass with length 50mm×width 30mm×height 1mm is first soaked in acetone for 10-60 minutes, then ultrasonically washed with ethanol solution for 5-60 minutes, and then cleaned with deionized water to obtain a clean surface. substrate.

[0040] (2) Preparation of sol mixture:

[0041] Preparation of titanium dioxide sol: Pour 120mL of absolute ethanol into a dry beaker, then slowly drop 30mL of butyl titanate into the beaker at a rate of 0.2mL per minute, and stir at a speed of 800r / s for 10 minutes; Then slowly add 2 mL of acetylacetone dropwise at a rate of 0.2 mL per minute, and continue to stir vigorously at a rate of 800 r / s for 10 min; add catalyst nitric acid dropwise at a rate of 0.2 mL per minute to adjust the pH to 2-3 In between, stir for 1 h to obtain titanium dioxide sol.

[0042] Preparation of silica sol: add 4mL tetraethyl orthosilicate, 4mL, and 4m deionized water into a beaker and stir; add 2mL of ammonia water...

Embodiment 2

[0046] (1) Ordinary float glass with a length of 50 mm × width 30 mm × height 1 mm is first soaked in acetone for 10-60 min, then ultrasonically washed with ethanol solution for 5-60 min, and then cleaned with deionized water to obtain a substrate with a clean surface.

[0047] (2) Preparation of sol mixture

[0048] Preparation of titanium dioxide sol: Pour 120mL of absolute ethanol into a dry beaker, then slowly drop 30mL of butyl titanate into the beaker at a rate of 0.2mL per minute, and stir at a speed of 800r / s for 10 minutes; Then slowly add 2 mL of acetylacetone dropwise at a rate of 0.2 mL per minute, and continue to stir vigorously at a rate of 800 r / s for 10 min; add catalyst nitric acid dropwise at a rate of 0.2 mL per minute to adjust the pH to 2-3 In between, stir for 1 h to obtain titanium dioxide sol.

[0049] Preparation of silica sol: add 4mL tetraethyl orthosilicate, 4mL, and 4m deionized water into a beaker and stir; add 2mL of ammonia water (concentration...

Embodiment 3

[0053] (1) Surface polishing: the ordinary float glass with length 50mm×width 30mm×height 1mm is first soaked in acetone for 10-60 minutes, then ultrasonically washed with ethanol solution for 5-60 minutes, and then cleaned with deionized water to obtain a clean surface. substrate.

[0054] (2) Preparation of sol mixture:

[0055] Preparation of titanium dioxide sol: Pour 120mL of absolute ethanol into a dry beaker, then slowly drop 30mL of butyl titanate into the beaker at a rate of 0.2mL per minute, and stir at a speed of 800r / s for 10 minutes; Then slowly add 2 mL of acetylacetone dropwise at a rate of 0.2 mL per minute, and continue to stir vigorously at a rate of 800 r / s for 10 min; add catalyst nitric acid dropwise at a rate of 0.2 mL per minute to adjust the pH to 2-3 In between, stir for 1 h to obtain titanium dioxide sol.

[0056] Preparation of silica sol: add 4mL tetraethyl orthosilicate, 4mL, and 4m deionized water into a beaker and stir; add 2mL of ammonia water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com