Long-life iron runner quick-dry castable and production method thereof

A long-life, castable technology, used in ceramic products, other household appliances, applications, etc., can solve problems such as the bulk density should not be too large, the material affects the thermal insulation effect, etc., to improve air permeability, improve explosion-proof performance, prolong The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

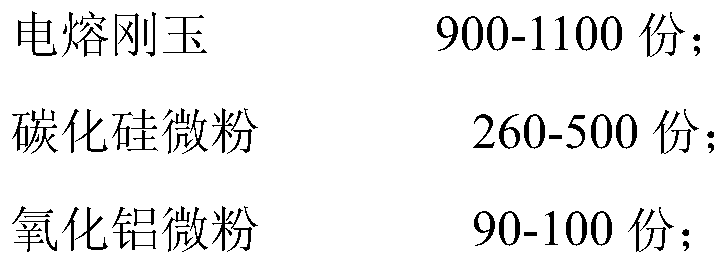

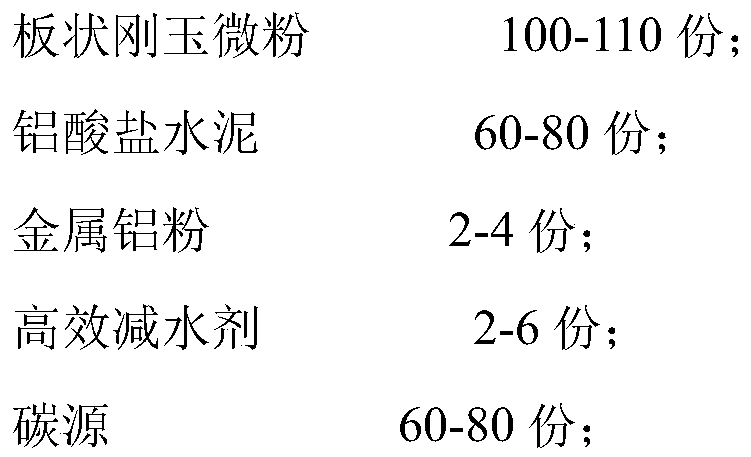

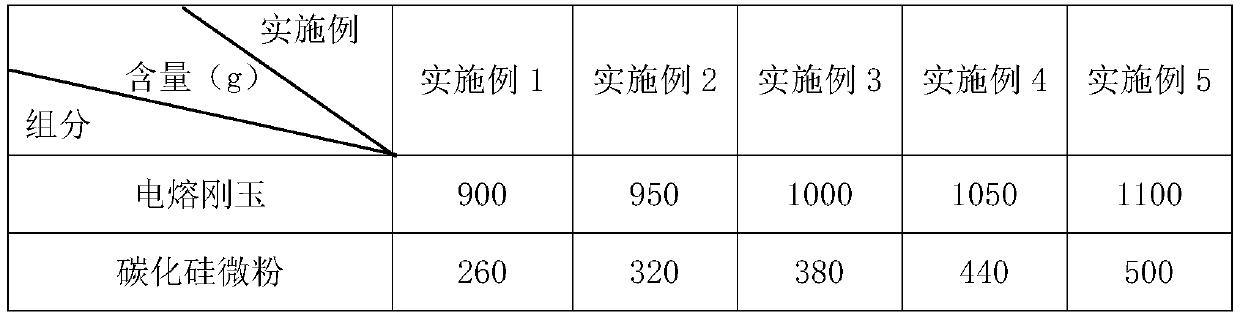

[0033] Embodiment 1: A long-life iron ditch quick-drying castable, including the components shown in Table 1 (1 part by weight=1g or 1kg). This embodiment takes 1 part by weight=1g as an example. Among them, the particle size range of fused corundum is 0-8mm, the particle size range of alumina micropowder is 0-2μm, and the particle size range of tabular corundum powder is 5μm. The particle size range of metal silicon powder is 0-0.044mm, and the particle size range of silicon carbide is 0-0.074mm. Metal aluminum powder is compounded by 0.154mm aluminum powder and 0.044mm aluminum powder with a weight ratio of 1:1. The carbon source is spherical pitch with a particle size of 0.1-0.3 mm. The water reducer is a polycarboxylate water reducer.

[0034] Each component content table of table 1 embodiment 1-5

[0035]

[0036]

[0037] The method for preparing the long-life iron ditch quick-drying castable comprises the following steps:

[0038] S1. Weigh each component with t...

Embodiment 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the contents of each component are as shown in Table 1.

Embodiment 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the contents of each component are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com