Method for using Miscanthus sinensis biochar as soil organic silicon fertilizer

A biochar and organosilicon technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of odorous harmful volatile organic compounds, complex process, environmental pollution, etc., to improve photosynthetic efficiency, simple process and long-lasting repair effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

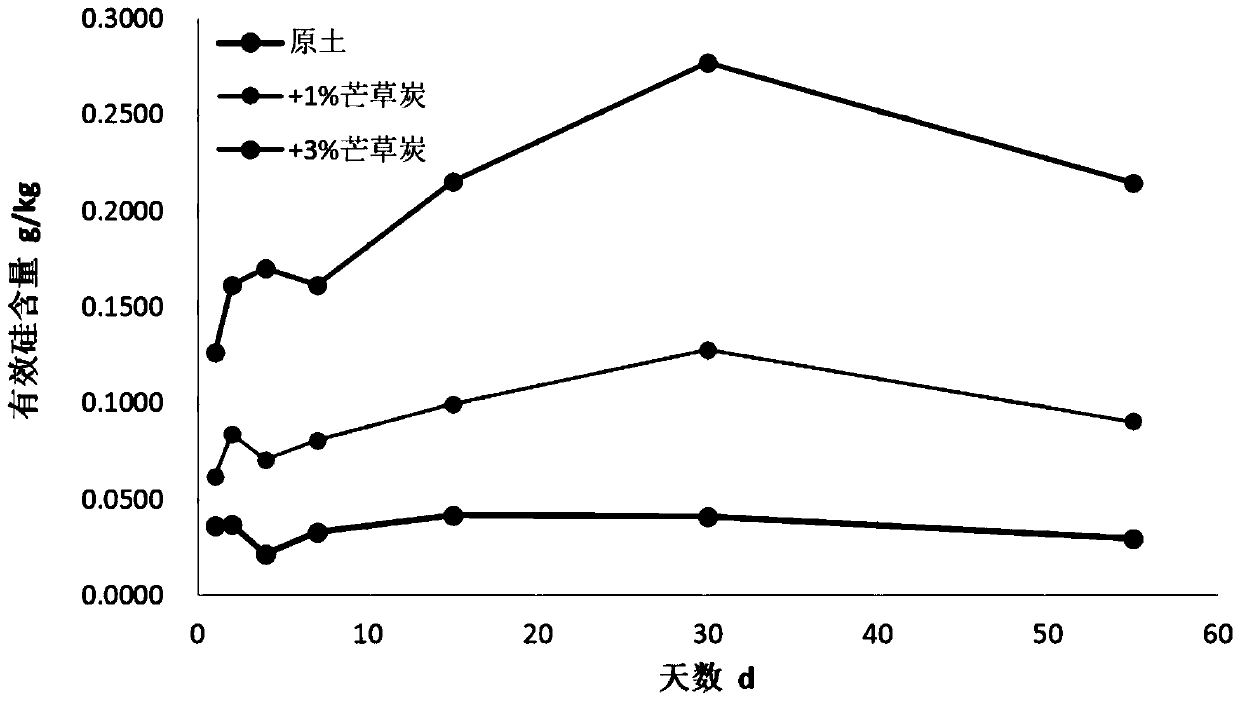

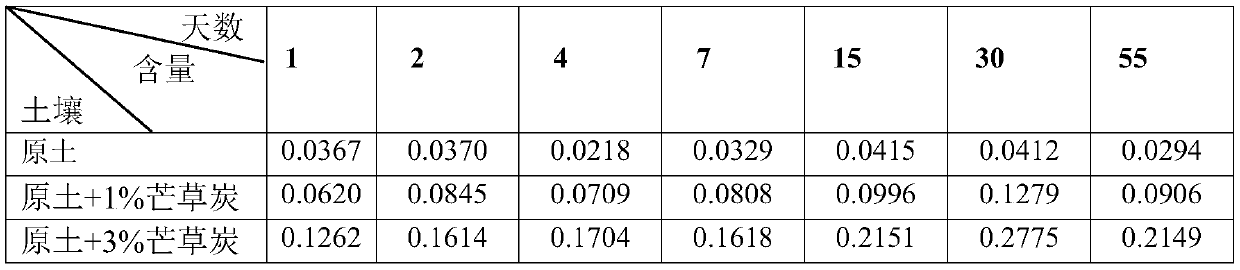

Embodiment 1

[0029] Miscanthus collected in the field was put into three sets of tube furnaces N 2 Under the atmosphere, the heating rate was 10°C / min, and the three groups of miscanthus were pyrolyzed and carbonized at 300°C, 500°C, and 700°C for 2 hours, respectively, to obtain Miscanthus biochar. After analysis, the total silicon content was enriched from 66.8±5.46mg / g in the original Miscanthus biomass to 223±4.32mg / g, 636±7.08mg / g and 722±7. 29.7 mg / g. Among them, the water-soluble silicon increased from 1.15±0.054mg / g in the original Miscanthus biomass to 4.39±0.29mg / g, 71.6±0.65mg / g and 87.2±1.02mg in charcoal at 300°C, 500°C, and 700°C, respectively / g.

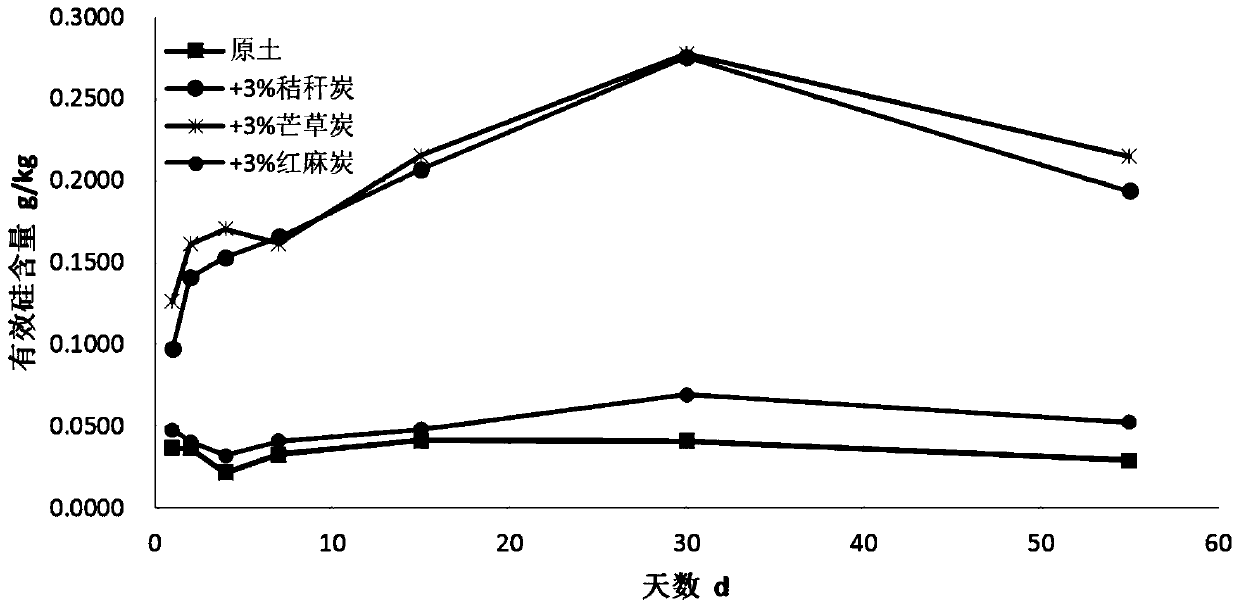

Embodiment 2

[0031] Put miscanthus collected in the field and rice straw collected in farmland into a tube furnaceN 2 Under the atmosphere, the heating rate was 10°C / min, and pyrolysis and carbonization were carried out at 700°C for 2 hours to obtain Miscanthus biochar and straw biochar, respectively. After analysis, the total silicon content (722±29.7mg / g) in miscanthus biochar was significantly higher than that in straw biochar (614±15.3mg / g), and its water-soluble silicon content (87.2±1.02mg / g) was also significantly higher and straw biochar (77.1±5.22mg / g), both of which are much higher than the total silicon and water-soluble silicon levels of soil in my country.

Embodiment 3

[0033] Put miscanthus collected in the field, rice husks collected in farmland and kenaf stalks harvested in the field into a tube furnaceN 2 Under atmosphere, the heating rate was 10°C / min, and pyrolysis and carbonization were carried out at 700°C for 2 hours to obtain Miscanthus biochar, rice husk biochar and kenaf biochar respectively. After analysis, the total silicon content of the three were 722±29.7mg / g, 771±25.2mg / g and 30.3±1.08mg / g respectively. In the long-term repeated water-soluble silicon leaching (the prepared biochar was leached for 24 hours each time, and the data were obtained after 15 rounds of leaching), it was found that the silicon dissolution of Miscanthus biochar was the highest and stable (35.8±1.39mg / g~75.0±1.64 mg / g), significantly higher than that of rice husk biochar (11.0±0.50mg / g~25.4±1.01mg / g), much higher than that of kenaf biochar (0.343±0.019mg / g~1.78±0.214mg / g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com