Method for producing oxamide by using synthesis ammonia and ammonium bicarbonate coproduction technology

A technology of ammonium bicarbonate and oxamide, which is applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of high production cost of oxamide, and achieve the effects of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

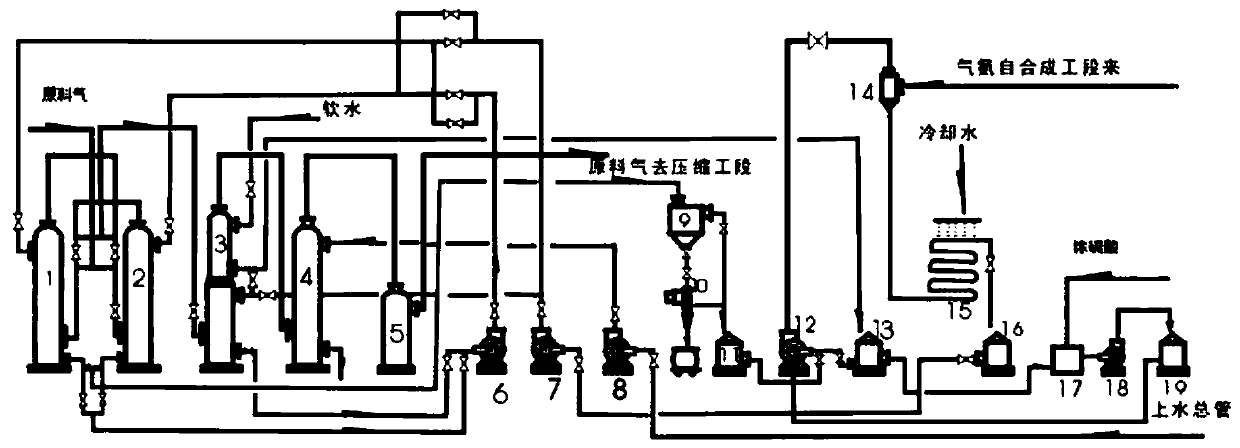

[0041] A kind of method of the present invention utilizes synthetic ammonia-co-production ammonium bicarbonate process to produce oxamide, specifically implements according to the following steps:

[0042] Step 1, utilizing synthetic ammonia-co-production ammonium bicarbonate process, the semi-water gas (H 2 36-37, CO32-35, N 2 21-22, CO 2 6-9) Send it into the gas cabinet, and then use the Roots blower to extract the semi-water gas in the gas cabinet. After desulfurization, it enters the first stage and the second stage of the compressor to compress to 0.7Mpa. After cooling to room temperature, cancel the transformation section and directly enter the carbonization workshop for removal Carbon dioxide, that is, raw material gas; the removed carbon dioxide reacts with ammonia water to produce ammonium bicarbonate;

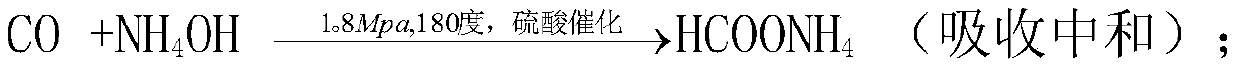

[0043] Step 2, the raw material gas obtained in step 1 is raised to 1.8Mpa through the three stages of the compressor, and the raw material gas after the raised pr...

Embodiment 2

[0052] A kind of method of the present invention utilizes synthetic ammonia-co-production ammonium bicarbonate process to produce oxamide, specifically implements according to the following steps:

[0053] Step 1, utilizing synthetic ammonia-co-production ammonium bicarbonate process, the semi-water gas (H 2 36-37, CO32-35, N 2 21-22, CO 2 6-9) Send it into the gas cabinet, and then use the Roots blower to extract the semi-water gas in the gas cabinet. After desulfurization, it enters the first stage and the second stage of the compressor to compress to 0.7Mpa. After cooling to room temperature, it enters the carbonization workshop to remove carbon dioxide, and the raw material is obtained gas; the removed carbon dioxide reacts with ammonia water to produce ammonium bicarbonate;

[0054] Step 2: Raise the pressure of the raw material gas obtained in step 1 to 1.7Mpa through three stages of the compressor, use heat transfer oil to heat the raw material gas after the pressure ...

Embodiment 3

[0063] A kind of method of the present invention utilizes synthetic ammonia-co-production ammonium bicarbonate process to produce oxamide, specifically implements according to the following steps:

[0064] Step 1, utilizing synthetic ammonia-co-production ammonium bicarbonate process, the semi-water gas (H 2 36-37, CO32-35, N 2 21-22, CO 2 6-9) Send it into the gas cabinet, and then use the Roots blower to extract the semi-water gas in the gas cabinet. After desulfurization, it enters the first stage and the second stage of the compressor to compress to 0.7Mpa. After cooling to room temperature, it enters the carbonization workshop to remove carbon dioxide, and the raw material is obtained gas; the removed carbon dioxide reacts with ammonia water to produce ammonium bicarbonate;

[0065] Step 2: Raise the pressure of the raw material gas obtained in step 1 to 1.9Mpa through three stages of the compressor, use heat transfer oil to heat the raw material gas after the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com