A coating alkali metal atom air cell curing system and its application method for prolonging the lifetime of atomic spin relaxation

A technology of atomic gas chamber and atomic spin, which is applied to furnace types, furnace components, furnace control devices, etc., can solve problems such as difficulty in controlling the density of alkali metal atoms, large magnetic resonance signal line width, and small magnetic resonance signal amplitude, etc., to achieve Uniform distribution of coating materials, prolonging the service life and prolonging the effect of relaxation life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Those of ordinary skill in the art can Some non-essential improvements and adjustments are made to the present invention according to the above-mentioned content of the invention.

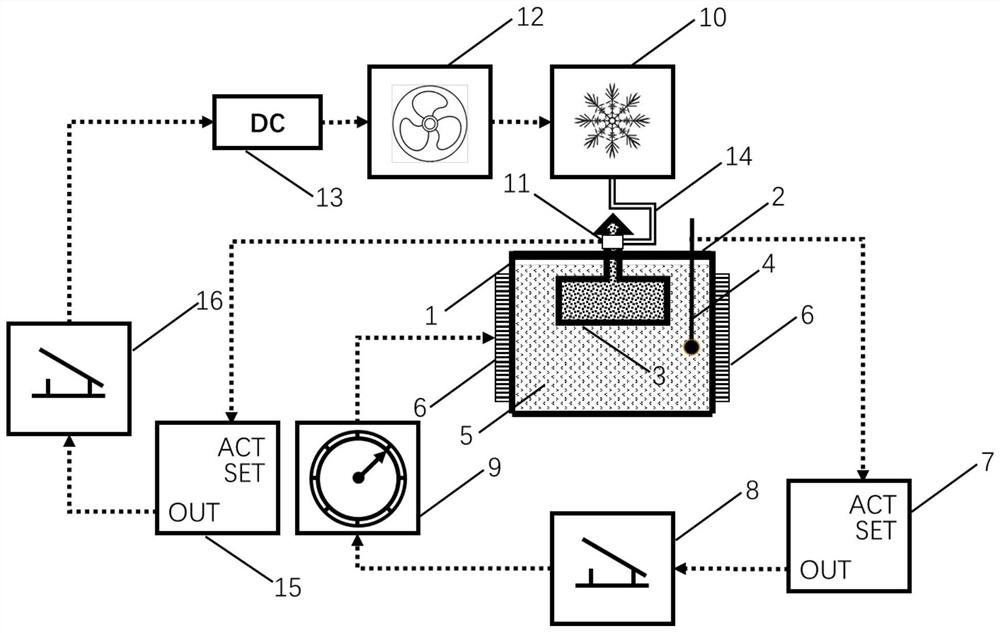

[0034] Such as figure 1 Shown is a schematic diagram of the main functional modules of the present invention.

[0035] For the atomic gas chamber heating temperature control furnace 1 made of high-temperature-resistant non-magnetic plastic materials, the inner wall coating material of the alkali metal atomic gas chamber 3 that needs to be matured is preheated to prevent the system from being damaged due to excessive temperature during use .

[0036] According to the alkali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com