Colored photosensitive resin composition, color filter and image display apparatus comprising same

A technology of photosensitive resin and composition, which is applied in the field of colored photosensitive resin composition and image display device, can solve the problems of poor reliability and stability such as heat resistance and light resistance, and achieve excellent reliability, heat resistance Excellent effect of light resistance and light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

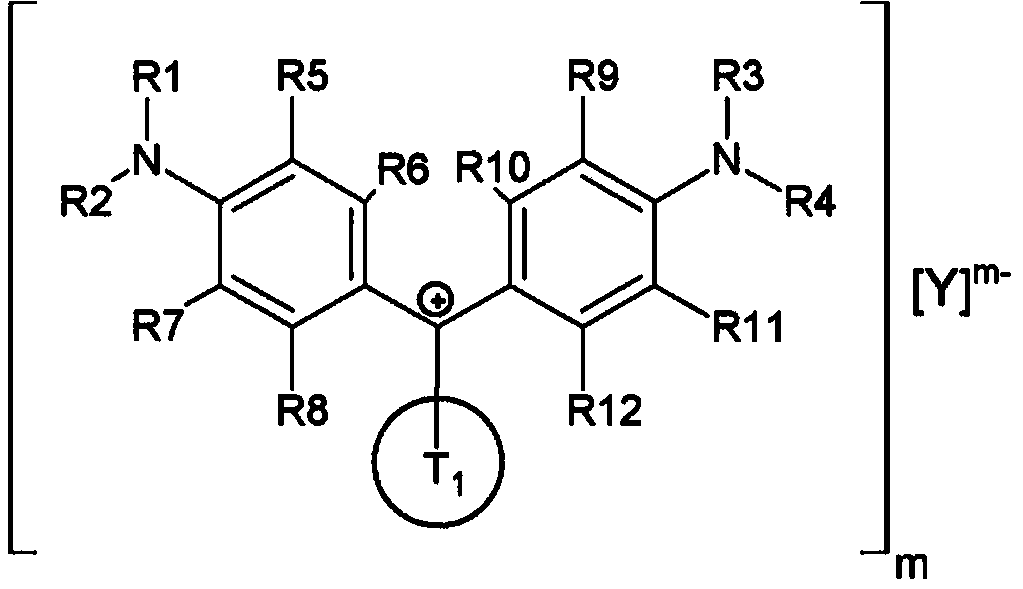

[0159] Synthesis Example 1: Compound of colorant (A-1)

[0160] The following reactions were carried out under a nitrogen atmosphere. After putting 15.3 parts of N-methylaniline (manufactured by Tokyo Chemical Industry Co., Ltd.) and 60 parts of N,N-dimethylformamide into a flask equipped with a condenser and a stirring device, the mixed solution was ice-cooled. Under ice cooling, 5.7 parts of 60% sodium hydride (manufactured by Tokyo Chemical Industry Co., Ltd.) was added little by little over 30 minutes, and stirred for 1 hour while raising the temperature to room temperature. 10.4 parts of 4,4'-difluorobenzophenone (manufactured by Tokyo Chemical Industry Co., Ltd.) was added little by little to the reaction solution, and stirred at room temperature for 24 hours. After adding the reaction liquid to 200 parts of ice water little by little, it was left standing at room temperature for 15 hours, and the water was removed by decantation to obtain a viscous solid as a residue. T...

Synthetic example 1-1

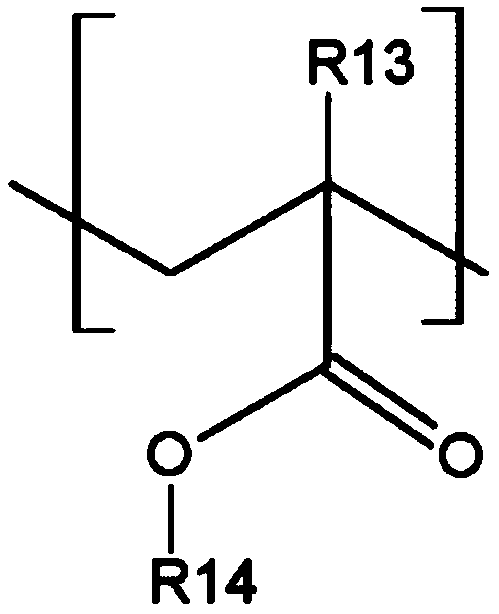

[0171] Synthesis Example 1-1: Resin for Colored Dispersion Liquid (B)

[0172] In a flask equipped with a reflux condenser, a dropping funnel and a stirrer, a nitrogen atmosphere was made by flowing nitrogen gas at 0.02 L / min, and 200 parts of 3-methoxy-1-butanol and 3-methoxybutanol were added. 105 parts of glycyl acetate were heated to 70°C while stirring. Next, 60 parts of methacrylic acid, 3,4-epoxy tricyclic 5.2.1.O 2,6 ] 240 parts of decyl acrylate was dissolved in 140 parts of 3-methoxybutyl acetate to prepare a solution, and the dissolved solution was dropped into a flask kept at 70° C. using a dropping funnel over 4 hours. On the other hand, 30 parts of polymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) was dissolved in 225 parts of 3-methoxybutyl acetate, and the resulting solution was used for another drop The funnel was dropped into the flask over 4 hours. After the dropwise addition of the polymerization initiator solution was completed, the solution ...

Synthetic example 2

[0175] Synthesis Example 2: Compound of Coloring Agent (A-2)

[0176] According to the method described in Synthesis Example 1, a phosphomolybdic acid solution was added to obtain a compound represented by the following formula (A'-5).

[0177] [Formula (A'-5)]

[0178]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com