Submerged-arc welding wire for high-rise building structure refractory steel

A submerged arc welding wire, high-rise building technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of Mo element increasing material cost and high processing cost, and achieve excellent comprehensive mechanical properties, low cost, The effect of high temperature tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

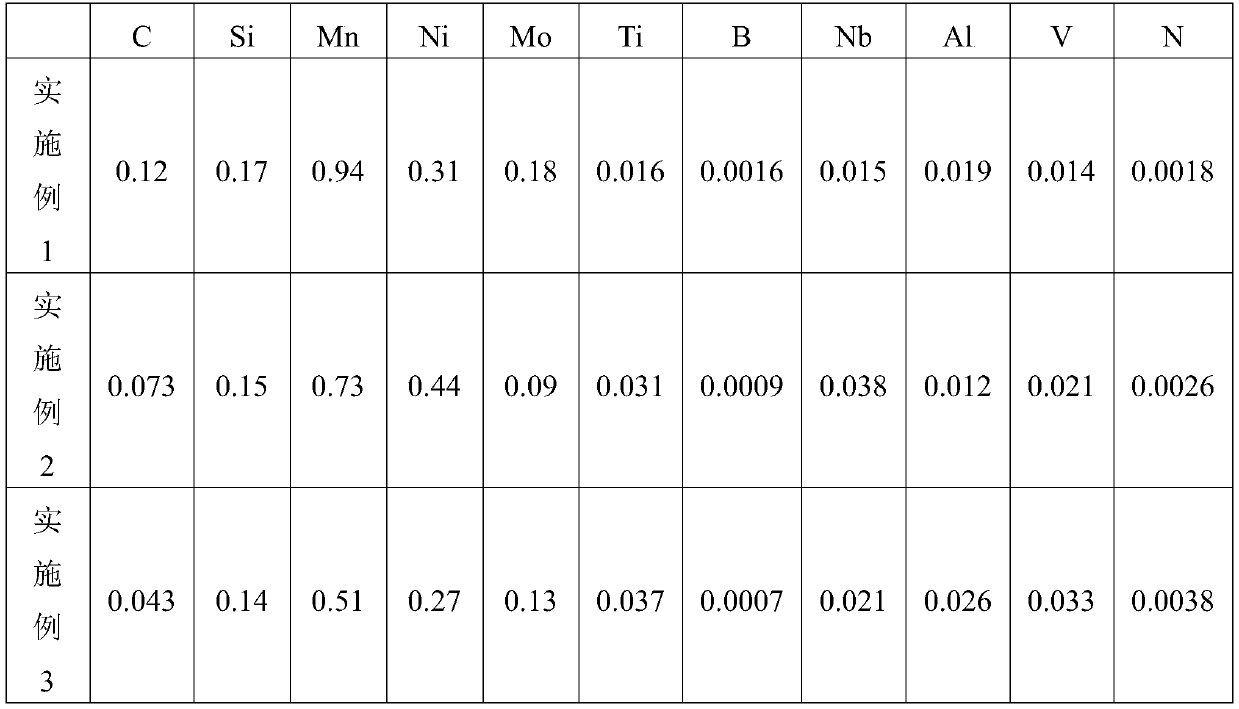

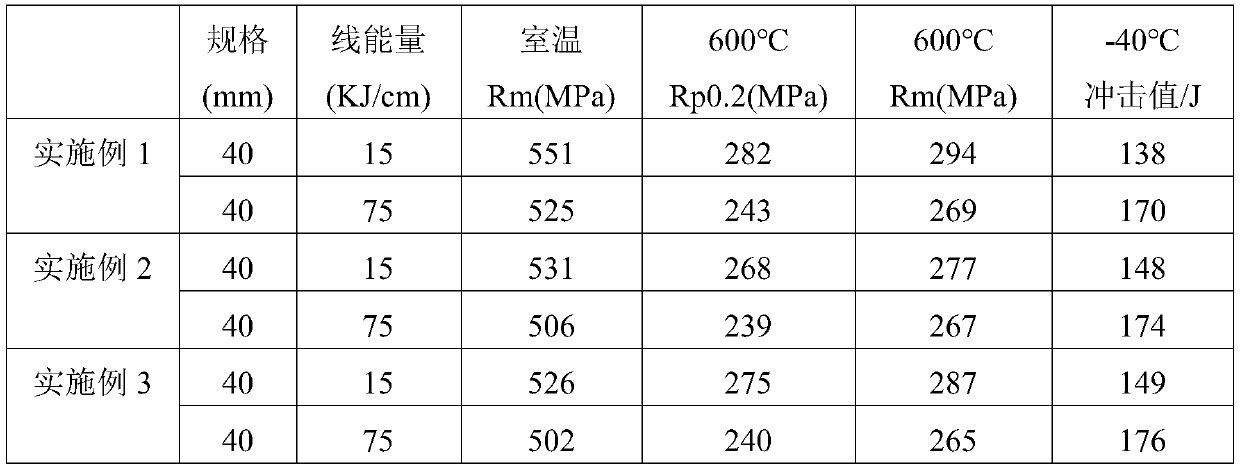

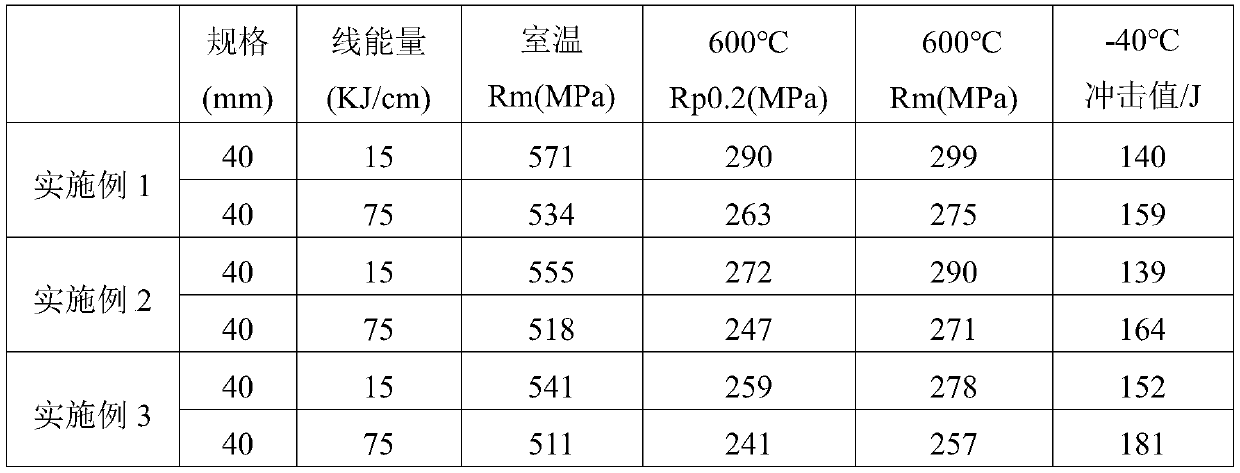

Embodiment 1

[0015] The preparation of submerged arc welding wire adopts existing equipment and technology. The mass percentage of its chemical composition is shown in Table 1. The welding plate is Q345FRE refractory steel with a thickness of 40mm. The welding heat input is 15KJ / cm and 75KJ / cm; the welding groove size, Sampling locations and test methods are carried out in accordance with the national standard GB / T 12470, and the judgment of test results is carried out in accordance with the national standard GB / T 28415-2012. The deposited metal with excellent comprehensive mechanical properties is obtained by welding with XUN121 flux.

Embodiment 2

[0017] The preparation of submerged arc welding wire adopts existing equipment and technology, and its chemical composition mass percentage is shown in Table 1, and the welding process is the same as that of Example 1.

Embodiment 3

[0019] The preparation of submerged arc welding wire adopts existing equipment and technology, and its chemical composition mass percentage is shown in Table 1, and the welding process is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com