Micro-channel boiling heat transfer system and method based on vapor-liquid multiphase fluid staggered division

A boiling heat transfer, multiphase fluid technology, applied in fluid velocity measurement, process for producing decorative surface effects, microstructure technology, etc. The pressure drop increases, the surface roughness decreases, etc., to achieve strong scientific innovation and technical practicability, increase the gas-liquid contact area, and achieve the effects of sensible heat and latent heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

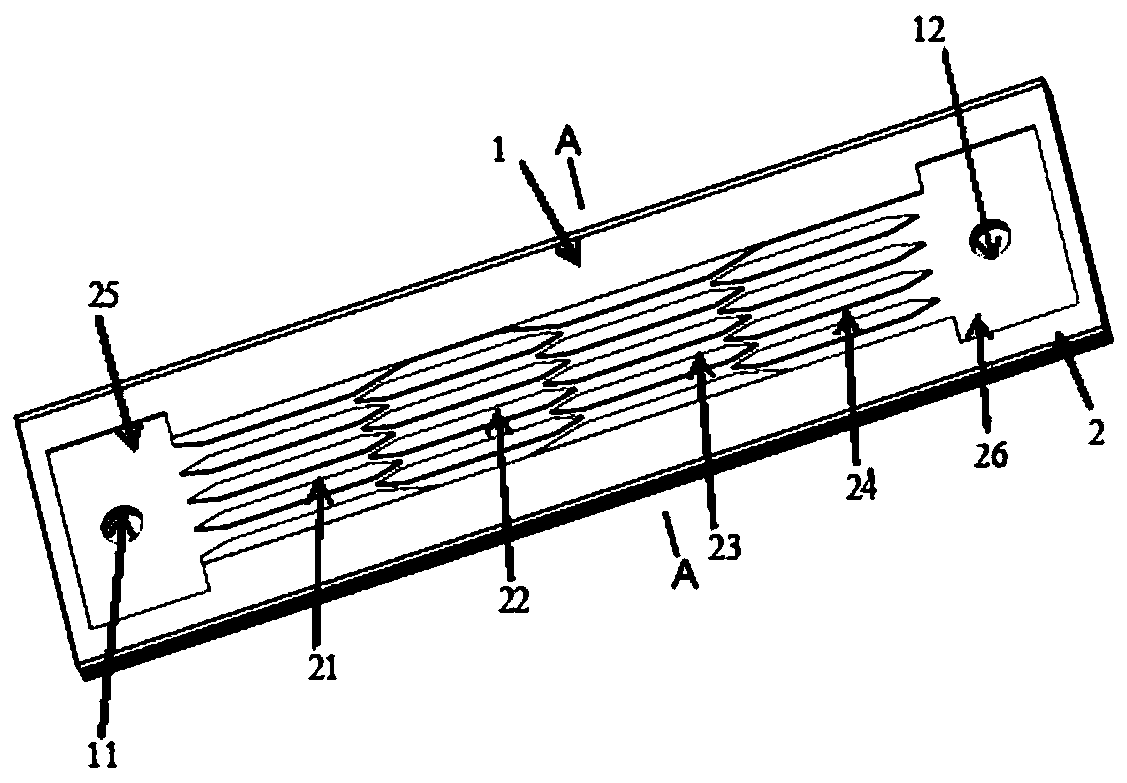

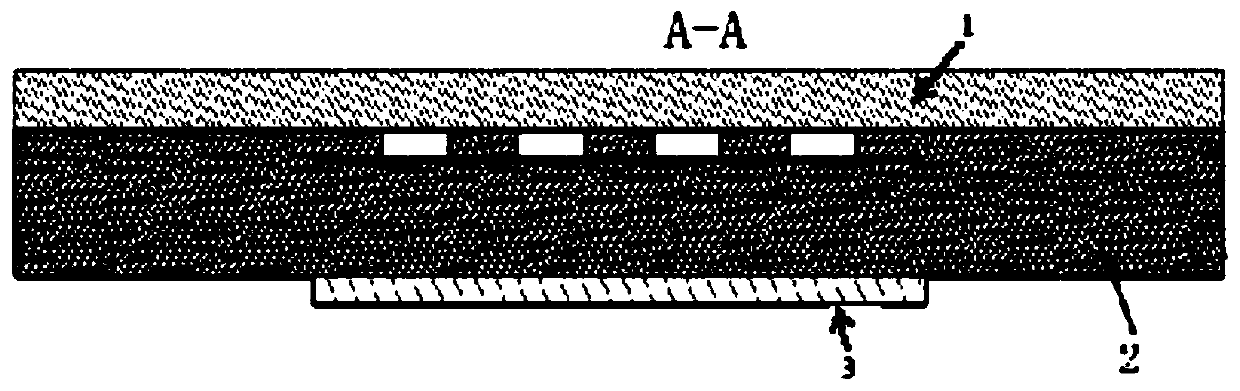

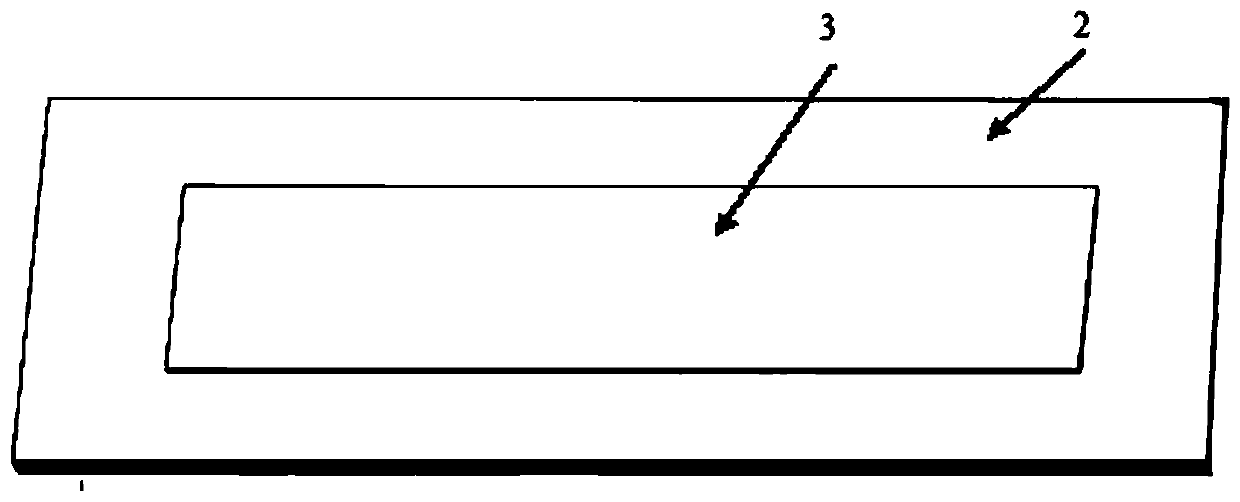

[0028] like Figure 1-4Shown is a microchannel boiling heat transfer system based on gas-liquid multiphase fluid staggered division, which consists of an upper cover plate 1 , a bottom fluid-based microchannel array plate 2 and a simulated heat source 3 . The upper cover plate has a liquid inlet 11 and a liquid outlet 12; the bottom layer has a first parallel microchannel array 21, a second parallel microchannel array 21, and a second parallel microchannel array plate 2 that are periodically staggered and arranged on the front of the microchannel array plate 2 based on fluid staggered divisions. Channel array 22, the third parallel microchannel array 23, the fourth parallel microchannel array 24, the inlet liquid storage tank 25 and the outlet liquid storage tank 26; The back side is facing the first parallel microchannel array 21, the second parallel microchannel array 22, the third parallel microchannel array 23, and the fourth parallel microchannel array 24 regions arranged...

Embodiment 2

[0039] like Figure 5 Shown is a microchannel boiling heat transfer enhancement method based on interlaced division of gas-liquid multiphase fluid. The single-phase liquid working medium enters the first parallel microchannels arranged in periodic interlaced divisions from the liquid inlet 11 through the inlet storage tank 25 Array 21, the second parallel microchannel array 22, the third parallel microchannel array 23, and the fourth parallel microchannel array 24. Under the heating heat flow of the simulated heat source 3, the working medium is periodically staggered and arranged in the microchannel array 21, Gas-liquid phase transition occurs in 22, 23, and 24 to form a multiphase flow, and the first parallel microchannel array 21, the second parallel microchannel array 22, the third parallel microchannel array 23, and the fourth parallel microchannel array 24 mutually The staggered area produces fluid segmentation, boundary layer detachment and redevelopment respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com