Method for obtaining high-purity squalene from vegetable oil deodorized distillate

A technology for deodorizing distillate and squalene, applied in distillation purification/separation, chemical instruments and methods, hydrocarbons, etc., can solve problems such as high pollution, low efficiency, etc., to solve the shortage of raw materials and solve the continuous market demand effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

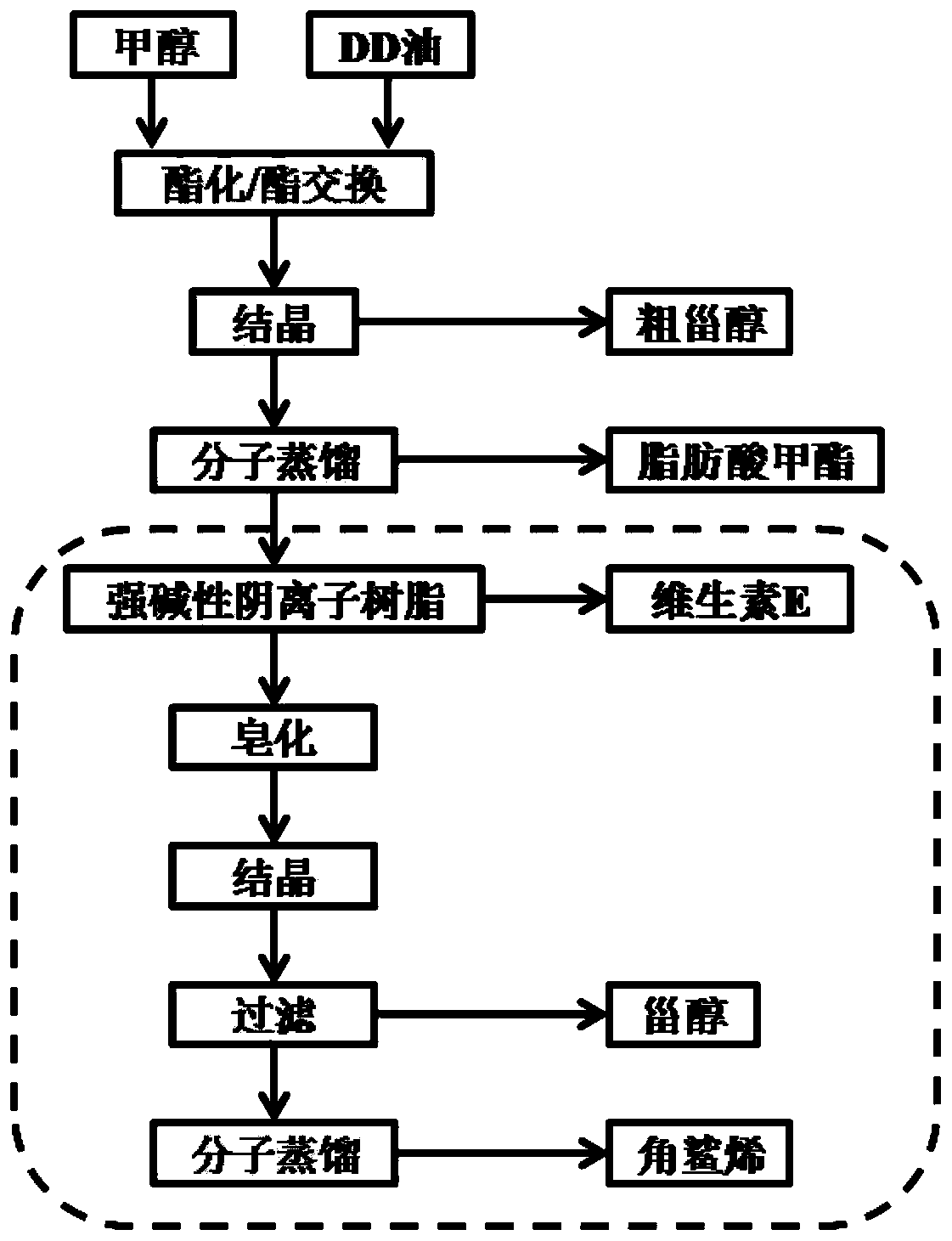

[0034] according to figure 1 Shown technological process, obtain squalene from vegetable oil deodorization distillate, concrete method is as follows:

[0035] 1. Preliminary enrichment of squalene

[0036] According to the volume ratio of vegetable oil deodorization distillate and methanol is 1:4, soybean oil deodorization distillate (containing 49.3% free fatty acid, 12.5% glyceride, 26.2% phytosterol, 10.8% vitamin E, 2.2% squalene ) and methanol are respectively placed in two raw material tanks, pumped into the primary pre-heater respectively through a high-pressure pump, preheated to 55°C and mixed in the mixer, and the resulting mixture is heated to 294°C by the secondary pre-heater Finally, it is pumped into a tubular fixed-bed reactor filled with magnesia catalyst particles for esterification and transesterification. The reaction temperature is 300° C., the pressure is 15 MPa, and the reaction time is 5 minutes. After the reaction, the reaction product enters the ga...

Embodiment 2

[0044] according to figure 1 Shown technological process, obtain squalene from vegetable oil deodorization distillate, concrete method is as follows:

[0045] 1. Preliminary enrichment of squalene

[0046] According to the volume ratio of vegetable oil deodorization distillate and methanol is 1:4, olive oil deodorization distillate (containing 54.5% free fatty acid, 10.1% glyceride, 14.4% phytosterol, 12.5% vitamin E, 3.9% squalene ) and methanol are respectively placed in two raw material tanks, pumped into the primary pre-heater respectively through a high-pressure pump, preheated to 50°C and mixed in the mixer, and the resulting mixture is heated to 300°C by the secondary pre-heater Finally, it is pumped into a tubular fixed-bed reactor filled with magnesia catalyst particles for esterification and transesterification. The reaction temperature is 310° C., the pressure is 16 MPa, and the reaction time is 6 minutes. After the reaction, the reaction product enters the gas-...

Embodiment 3

[0054] according to figure 1 Shown technological process, obtain squalene from vegetable oil deodorization distillate, concrete method is as follows:

[0055] 1. Preliminary enrichment of squalene

[0056]According to the volume ratio of vegetable oil deodorization distillate and methanol is 1:4, corn oil deodorization distillate (containing 61.3% free fatty acid, 11.0% glyceride, 15.1% phytosterol, 9.9% vitamin E, 1.5% squalene ) and methanol are respectively placed in two raw material tanks, pumped into the primary pre-heater respectively through a high-pressure pump, preheated to 48°C and mixed in the mixer, and the resulting mixture is heated to 300°C by the secondary pre-heater Finally, it is pumped into a tubular fixed-bed reactor filled with magnesia catalyst particles for esterification and transesterification. The reaction temperature is 305° C., the pressure is 18 MPa, and the reaction time is 7 minutes. After the reaction, the reaction product enters the gas-liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com