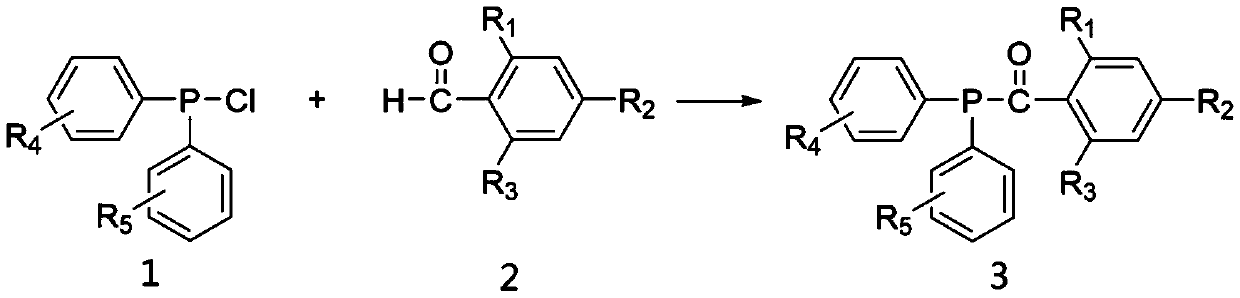

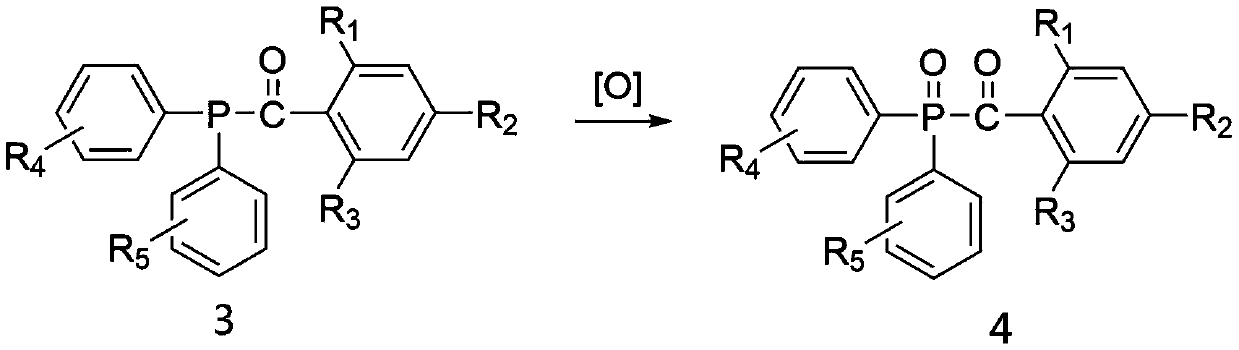

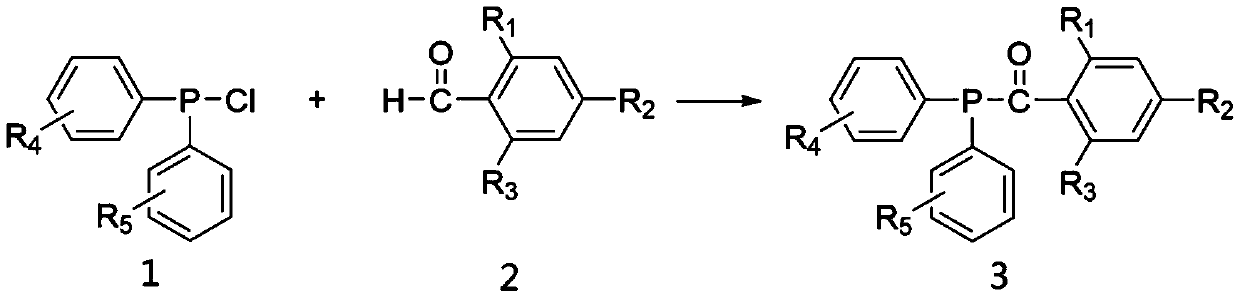

Continuous preparation method of trimethylbenzoyl-diphenylphosphine oxide compound

A technology of trimethylbenzoyl and diphenylphosphine oxide, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems such as high risk factors and large environmental pollution problems, to achieve the effect of high safety, environmental protection, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The molar flow ratio of 2,4,6-trimethylbenzaldehyde to diphenylphosphine chloride or its derivatives in the pipeline reactor is 1:1, and the reaction raw materials are all fed in the form of solution. According to 74g 2,4,6-trimethylbenzaldehyde, add 400g chlorobenzene to prepare the chlorobenzene solution of 2,4,6-trimethylbenzaldehyde, the concentration is 1.0mol / L; 110g diphenylphosphine chloride is added 400g Chlorobenzene Prepare a chlorobenzene solution of diphenylphosphine chloride with a concentration of 1.0mol / L. The volume flow rate of 2,4,6-trimethylbenzaldehyde solution is 50mL / min, and the volume flow rate of diphenylphosphine chloride is 45mL / min. The reaction was carried out at 2 bar pressure and 30° C. with a residence time of 10 s. Subsequently, the oxidation solution was fed with a volume flow rate of 47 mL / min. According to 0.8g V 2 o 5 , 400g chlorobenzene and 90g tert-butanol peroxide to configure the oxidation solution. The reaction was carrie...

Embodiment 2

[0036] The molar flow ratio of benzaldehyde to diphenylphosphine chloride or its derivatives in the pipeline reactor is 1:1, and the reaction raw materials are all fed in the form of solution. Add 400g chlorobenzene to prepare the chlorobenzene solution of 2 benzaldehyde according to 53g benzaldehyde, concentration is 1.0mol / L; mol / L. The volume flow of benzaldehyde solution is 36mL / min, and the volume flow of diphenylphosphine chloride is 45mL / min. The reaction was carried out at 2 bar pressure and 40° C. with a residence time of 15 s. Subsequently, the oxidation solution starts to feed. According to 0.8g V 2 o 5 , 400g chlorobenzene and 90g tert-butanol peroxide to configure the oxidation solution. The reaction was carried out at 2 bar pressure and 40° C. with a residence time of 10 s. The reaction solution was analyzed by HPLC, and the conversion rate of the product was 98.5%. The reaction solution is precipitated and recrystallized to obtain a finished product with ...

Embodiment 3

[0038]The molar flow ratio of 2,4,6-triethylbenzaldehyde to diphenylphosphine chloride or its derivatives in the pipeline reactor is 1:1, and the reaction raw materials are all fed in the form of solution. According to 95g 2,4,6-triethylbenzaldehyde, add 400g chlorobenzene to prepare the chlorobenzene solution of 2,4,6-triethylbenzaldehyde, the concentration is 1.0mol / L; 110g diphenylphosphine chloride is added 400g Chlorobenzene Prepare a chlorobenzene solution of diphenylphosphine chloride with a concentration of 1.0mol / L. The volume flow rate of 2,4,6-trimethylbenzaldehyde solution is 63mL / min, and the volume flow rate of diphenylphosphine chloride is 45mL / min. The reaction was carried out at 2 bar pressure and 30° C. with a residence time of 10 s. Subsequently, the oxidation solution was fed with a volume flow rate of 47 mL / min. According to 0.8g V 2 o 5 , 400g chlorobenzene and 90g tert-butanol peroxide to configure the oxidation solution. The reaction was carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com